Polar plate dividing mechanism and automatic plate-wrapping assembly device for polar plate

A plate, automatic technology, applied in sustainable manufacturing/processing, climate sustainability, final product manufacturing, etc., can solve the problems of high labor intensity and low production efficiency of assembly workers, and improve product quality and production capacity. Strong and easy positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be further illustrated and described below through specific embodiments.

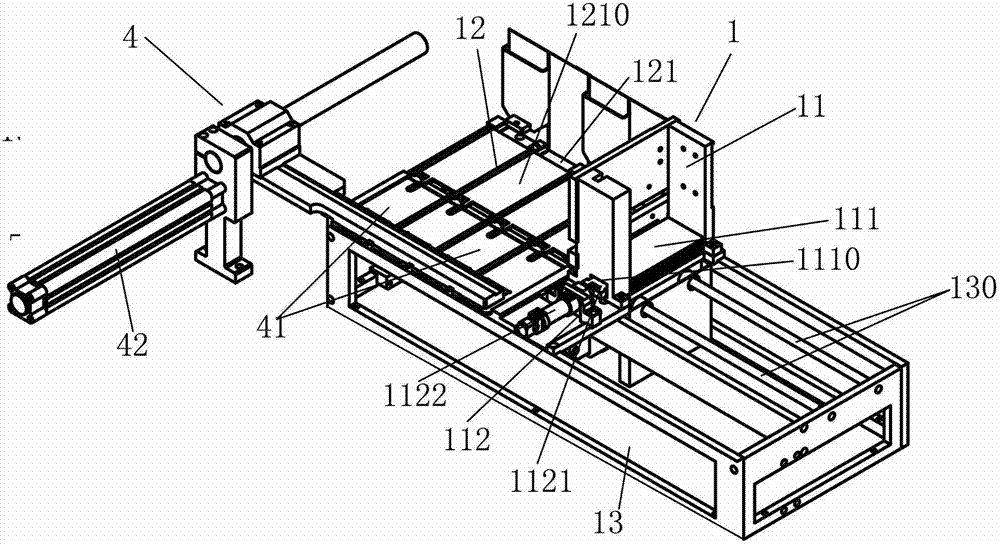

[0042] Such as figure 1 The pole plate splitting mechanism 1 shown includes a pole plate stacking part 11, a slice part 12 and a support frame 13; the pole plate stacking part 11 includes a pole plate stacking area 111 and a blocking mechanism 112, the blocking mechanism 112 includes a blocking plate 1121 and a first cylinder 1122 that drives the blocking plate 1121, and a through hole for the free end of the blocking plate 1121 to enter its interior is provided on a side wall of the plate stacking area 111 1110; the slice part 12 includes a slice plate 121 that is slidingly fitted under the plate stacking part 11 and a second cylinder (not shown) that drives the slice plate, and the slice plate 121 is There are four single plate placement areas 1210 . The support frame 13 is provided with a guide rail 130, the pole plate stacking part 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com