Preparation method of linear Fresnel lens and Fresnel lens prepared by preparation method

A linear Fresnel and lens technology, applied in the field of Fresnel lenses, can solve the problems of Fresnel lenses such as poor weather resistance, complicated preparation process, and low production efficiency, and achieve easy operation, simple preparation method, and overcome poor weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

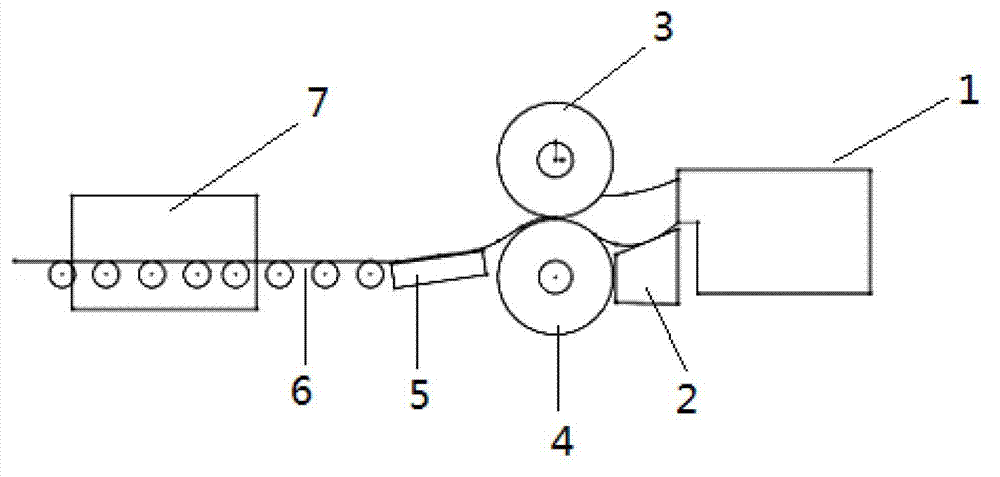

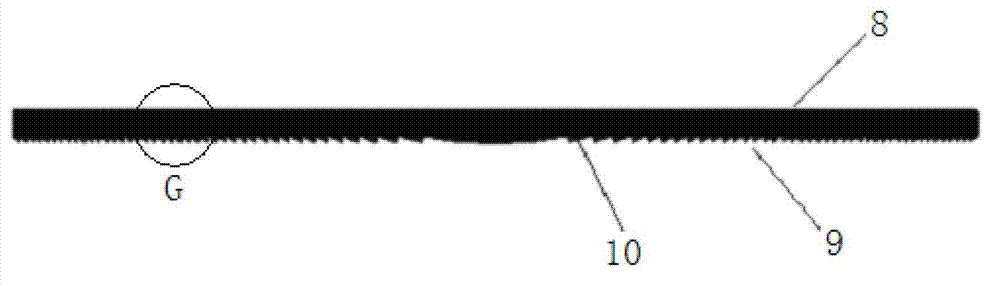

[0034] Such as figure 1 As shown, the equipment of the preparation method of the linear Fresnel lens of the present invention comprises in sequence: a melting device, a deflector, an upper pressure roller, a lower pressure roller, a guide cooling plate, a conveying device, an annealing kiln, wherein the upper pressure roller and One of the lower pressure rollers is a flat smooth roller, and the other is a mold roller engraved with tooth patterns; the upper pressure roller and / or the lower pressure roller are hollow rollers that can pass cooling water, and the upper pressure roller and The distance between the lower pressing rollers is 5mm, the rolling pressure is 100MPa, and the rolling speed is 170m / h; the viscosity of the glass before rolling is 10 3 dPas, the viscosity of the glass after rolling is 10 7 dPas; guide the cooling plate to cool to the viscosity of the glass is 10 13 dPas; annealing viscosity is 10 13 dPas, the annealing time is 15 minutes. After passing thr...

Embodiment 2

[0037] Such as figure 1 As shown, the equipment of the preparation method of the linear Fresnel lens of the present invention comprises in sequence: a melting device, a deflector, an upper pressure roller, a lower pressure roller, a guide cooling plate, a conveying device, an annealing kiln, wherein the upper pressure roller and One of the lower pressure rollers is a flat smooth roller, and the other is a mold roller engraved with tooth patterns; the upper pressure roller and / or the lower pressure roller are hollow rollers that can pass cooling water, and the upper pressure roller and The distance between the lower pressing rollers is 7mm, the rolling pressure is 100MPa, and the rolling speed is 150m / h; the viscosity of the glass before rolling is 10 5 dPas, the viscosity of the glass after rolling is 10 11 dPas; guide the cooling plate to cool to the viscosity of the glass is 10 13 dPas; the annealed viscosity is 4×10 14 dPas, the annealing time is 15 minutes. After the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com