Dried noodle smoothness detection device

A detection device and smoothness technology, applied in the direction of measuring device, mechanical device, instrument, etc., can solve the problems of not detecting the surface smoothness of noodles, the process of obtaining parameters is not objective, and will vary from person to person, etc., to achieve scientific detection methods. Reasonable, simple structure, good evaluation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

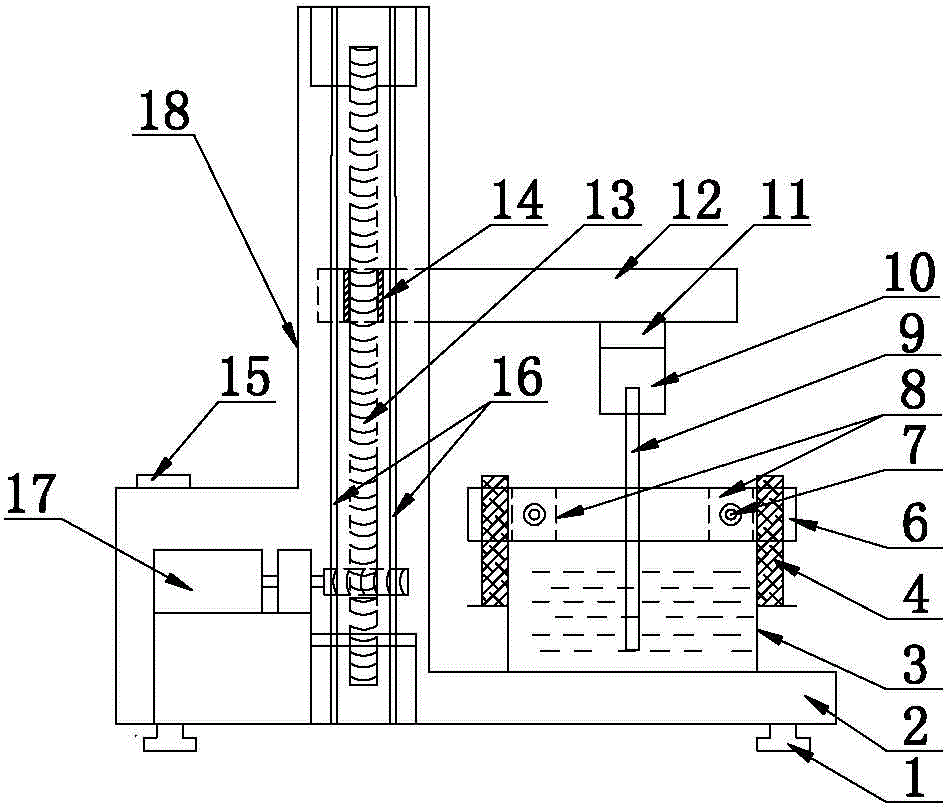

[0018] by figure 1 , figure 2 It can be seen that a device for detecting the smoothness of dried noodles is characterized in that it includes a base 2, on which a fixing frame 18, a noodle holding mechanism, and a power 17 are provided. The fixing frame 18 is provided with a power 17 that can be moved vertically. The lifting arm 12 is provided with an upper clamp 10 connected to the mechanical sensor 11, and the upper clamp 10 is located above the noodle clamping mechanism.

[0019] The fixing frame 18 of the present invention includes a positioning rod 16 and a screw rod 13 driven by a power 17. The lifting arm 12 is connected to the screw rod 13 through a nut 14. The lifting arm 12 moves vertically along the positioning rod 16 as the screw rod 13 rotates. movement.

[0020] In the present invention, for the accuracy of the experimental data, the noodle clamping mechanism includes a fixed clamping rod 5 and a movable clamping rod 6 which are mutually clamped. The elastic pressing...

Embodiment 2

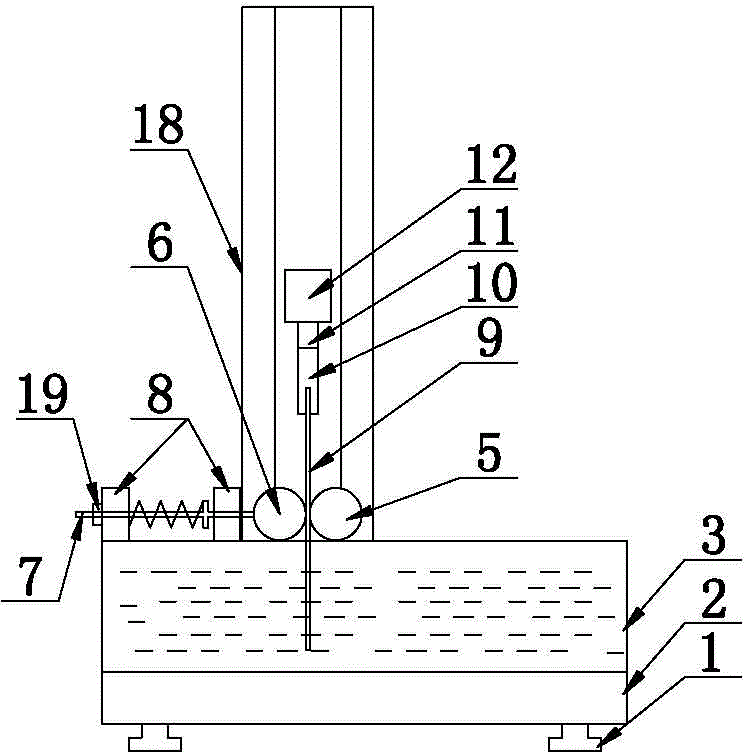

[0036] The fixing frame 18 of the present invention includes a transmission chain 13 driven by a gear driven by a power 17. The lifting arm 12 is fixed on a node of the transmission chain 13, and the lifting arm 12 moves vertically up and down with the lifting of the node of the transmission chain 13 .

[0037] When the present invention is started, the power 17 (that is, the speed-regulating motor) drives the transmission chain 13 to rotate through the gear of the reducer, thereby driving the lifting arm 12 fixed on the node of the transmission chain 13 to rise vertically at a constant speed, the mechanical sensor 11, the upper clamp 10 rises at a constant speed with the lifting arm 12, and then drives the cooked noodle section 9 to rise. During the ascending process, the mechanical sensor 11 detects the resistance experienced by the cooked noodle section 9 ascending, that is, the cooked noodle section 9 is in the fixed clamp 5, movable clamp The friction force generated on the ...

Embodiment 3

[0040] The fixing frame 18 of the present invention includes a rack 13 driven by a gear driven by a power 17. A lifting arm 12 is fixed to the upper end of the rack 13, and the lifting arm 12 moves vertically and vertically with the lifting of the rack 13.

[0041] When the present invention is started, the power 17 (that is, the speed-regulating motor) drives the rack 13 to rise through the gear rotation of the reducer, thereby driving the lifting arm 12 fixed on the upper end of the rack 13 to rise vertically at a constant speed. The mechanical sensor 11 and the upper clamp 10 As the lifting arm 12 rises at a constant speed, it drives the cooked noodle section 9 to rise. During the ascending process, the mechanical sensor 11 detects the resistance experienced by the cooked noodle section 9 when it rises, that is, the cooked noodle section 9 is in the fixed clamp 5 and movable clamp. The friction force generated by the surface under the action of 6. After the single detection is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com