Preparation method of rare-earth doped nanometer spherical CePo4 material

A rare earth doping and nano-technology, which is applied in the field of preparation of hexagonal nano-spherical CePO4 particle materials, can solve problems such as low friction coefficient, and achieve the effects of simple preparation method, energy saving and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

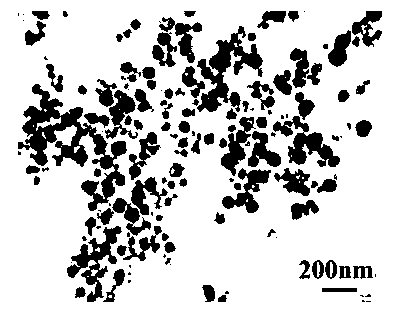

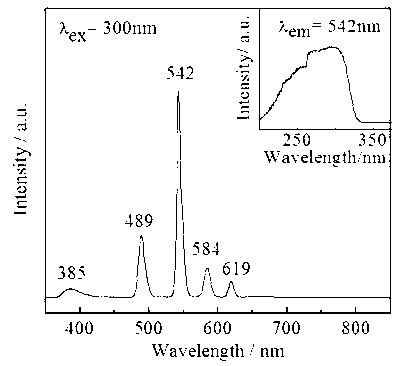

Embodiment 1

[0026] Weigh commercially available spectrally pure cerium sulfate tetrahydrate (Ce(SO 4 ) 2 4H 2 O) Reagent 101.075g (0.25mol), is mixed with 0.25 mol / liter of Ce(SO 4 ) 2 solution. Take by weighing the concentrated phosphoric acid 230.6g (containing 2mol H 3 PO 4 ), prepared as 2 mol / L H 3 PO 4 solution. Measure 10mL of Ce(SO 4 ) 2 Solution, according to absolute ethanol / Ce(SO 4 ) 2 The solution volume ratio is 7:1, Ce 4+ / polyoxyethylene ether-polyoxypropylene ether-polyoxyethylene ether triblock copolymer (P123, 5800) proportioning is 0.0005mol:1g, takes by weighing 55g dehydrated alcohol and 5g P123 respectively, joins Ce(SO 4 ) 2 solution and mix well. Press PO 4 3- / C 4+ =1:1 (molar ratio), measure 1.25mL of H with a concentration of 2 mol / L 3 PO 4 Solution, added to the above mixed solution at a rate of 0.1mL / min under stirring conditions to generate a cerium phosphate mesophase precursor, continue to stir for 2h after the dropwise addition, and the...

Embodiment 2

[0028] Using the same steps as in Example 1, the prepared concentration is 0.25 mol / liter of Ce(SO 4 ) 2 solution and 2 mol / L H 3 PO 4 solution. Measure 13mL of Ce(SO 4 ) 2 Solution, according to absolute ethanol / Ce(SO 4 ) 2 The solution volume ratio is 5:1, Ce 4+ / polyoxyethylene ether-polyoxypropylene ether-polyoxyethylene ether triblock copolymer (P123, 5800) proportioning is 0.0005mol:1g, takes by weighing 51g dehydrated alcohol and 6.5g P123 respectively, joins Ce(SO 4 ) 2 solution and mix well. Press PO 4 3- / C 4+ =1:1 (molar ratio), measure 1.625mL of H with a concentration of 2 mol / L 3 PO 4 Solution, under stirring condition, join in the above-mentioned mixed solution with the drop speed of 0.1mL / min, generate cerium phosphate mesophase precursor, all the other steps are identical with embodiment 1, obtain white hexagonal crystal phase nano-spherical CePO 4 particles. The product was characterized by XRD as hexagonal CePO 4 Pure phase, the product obta...

Embodiment 3

[0030] Using the same steps as in Example 1, the prepared concentration is 0.25 mol / liter of Ce(SO 4 ) 2 solution and 2 mol / L H 3 PO 4 solution. Measure 16mL of Ce(SO 4 ) 2 Solution, according to absolute ethanol / Ce(SO 4 ) 2 The solution volume ratio is 4:1, Ce 4+ / polyoxyethylene ether-polyoxypropylene ether-polyoxyethylene ether triblock copolymer (P123, 5800) proportioning is 0.0005mol:1g, takes by weighing 50g dehydrated alcohol and 8g P123 respectively and joins Ce(SO 4 ) 2 solution and mix well. Press PO 4 3- / C 4+ =1:1 (molar ratio), measure 2.0 mL of H with a concentration of 2 mol / L 3 PO 4 Solution, under stirring condition, join in the above-mentioned mixed solution with the drop speed of 0.1mL / min, generate cerium phosphate mesophase precursor, all the other steps are identical with embodiment 1, obtain white hexagonal crystal phase nano-spherical CePO 4 particles. The product was characterized by XRD as hexagonal CePO 4 Pure phase, the product obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com