Full-automatic transversal multi-shaft milling and drilling machine

A multi-axis drilling, fully automatic technology, applied in other manufacturing equipment/tools, large fixed members, metal processing machinery parts, etc., can solve the problems of low processing accuracy, manual operation of loading and discharging, and low processing efficiency, Achieve the effects of high machining accuracy, improved charging efficiency, and high work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

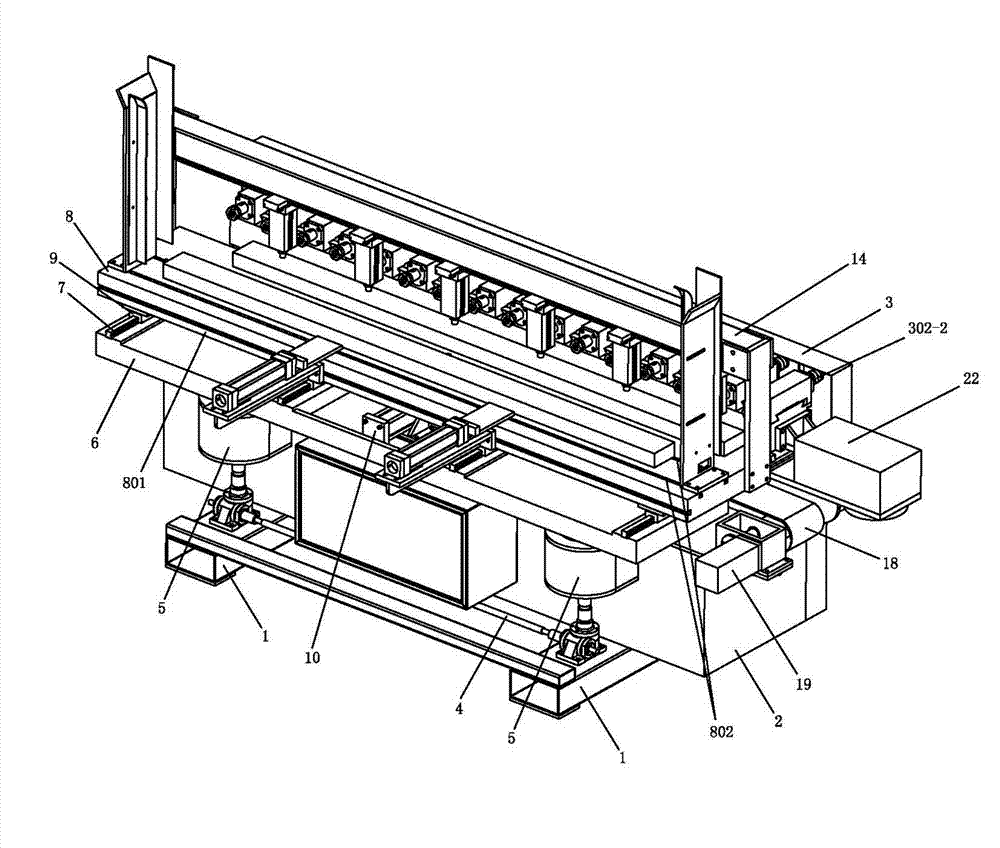

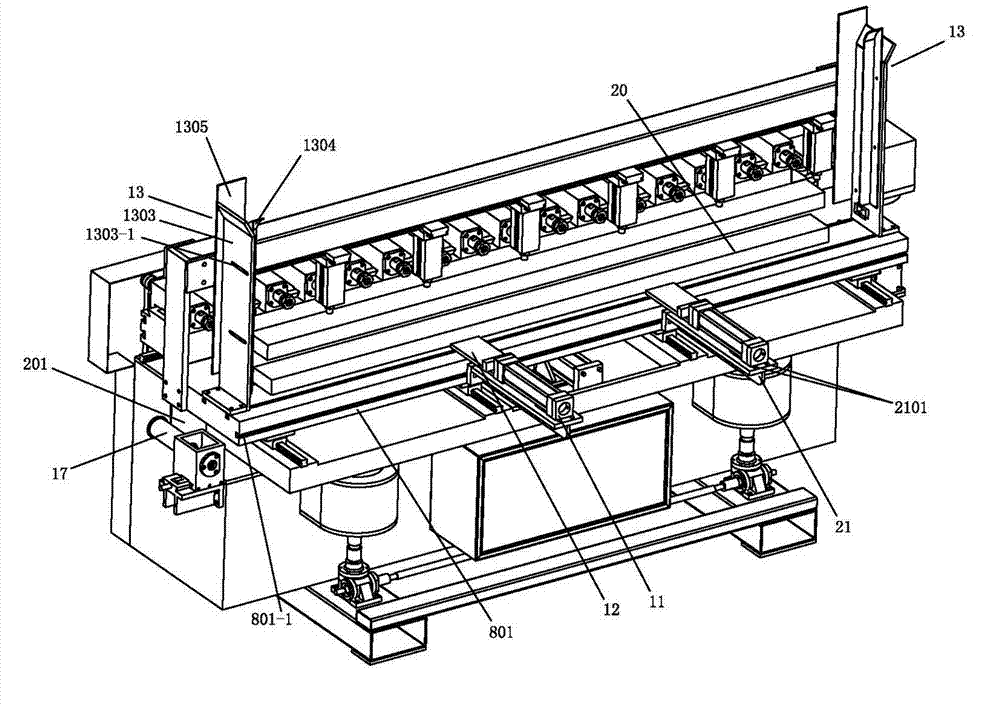

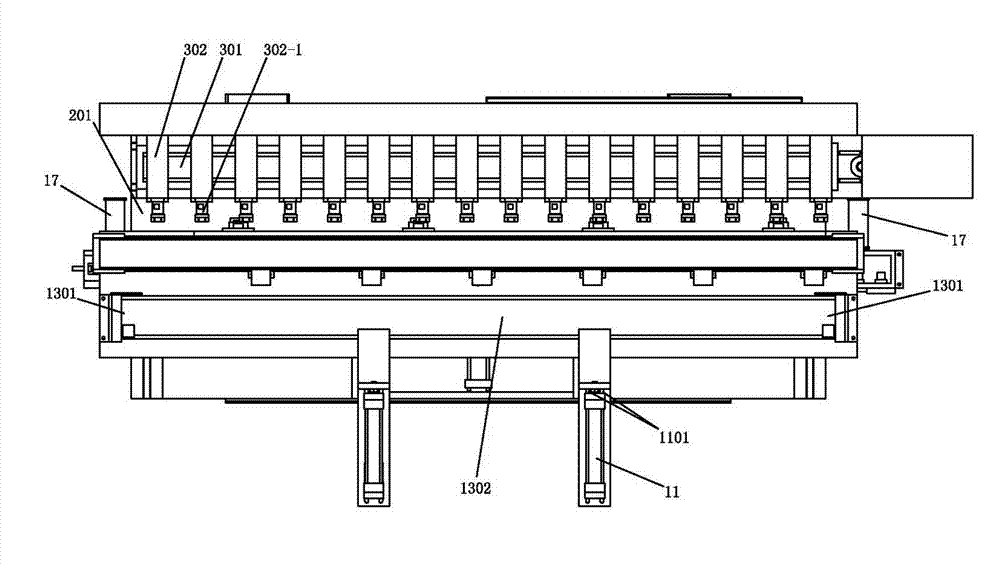

[0023] Such as Figure 1 to Figure 4 As shown, a fully automatic horizontal multi-axis drilling and milling machine includes a frame 1, the rear end of the frame 1 is provided with a fixed workbench 2, and the fixed workbench 2 is horizontally extended with multiple groups of spindle drilling and milling devices 3, and its features are:

[0024] Both sides of the front end of the frame 1 are equipped with two lifting mechanisms 5 connected by a synchronous connecting shaft 4, and the tops of the two lifting mechanisms 5 are connected with a lifting platform 6, and a plurality of longitudinal guide rails 7 are arranged on the lifting platform 6, and a sliding workbench 8 The slider 9 slides and sits on the longitudinal slide rail 7, and the lifting platform 6 is equipped with a longitudinal drive cylinder 10 that drives the sliding table 8 to slide back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com