Heavy duty tire

一种轮胎、轮胎周向的技术,应用在重型轮胎、充气轮胎、轮胎零部件等方向,能够解决胎面胎肩部不均匀磨损、边缘部增加等问题,达到提高湿地性能、抑制不均匀磨损的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

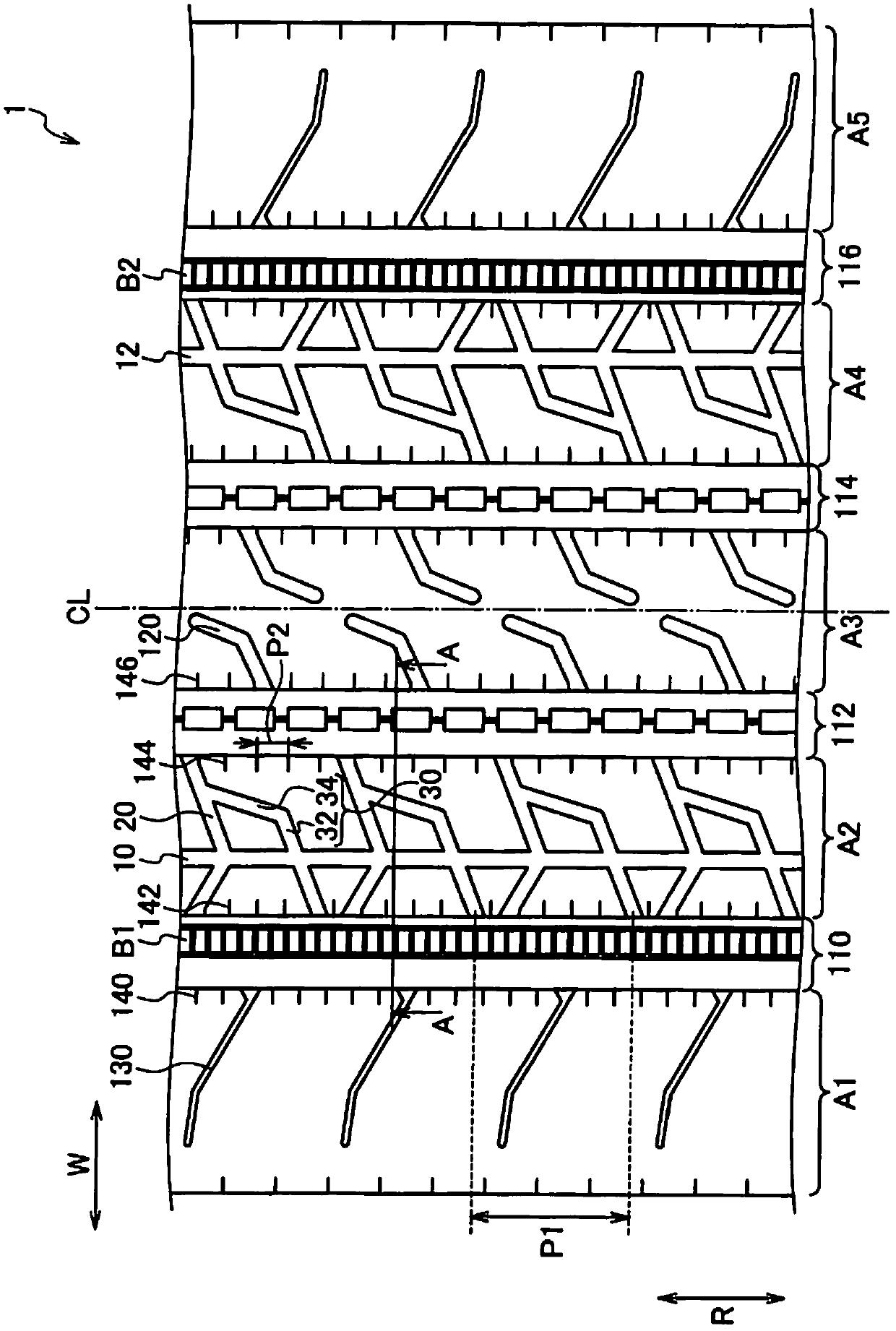

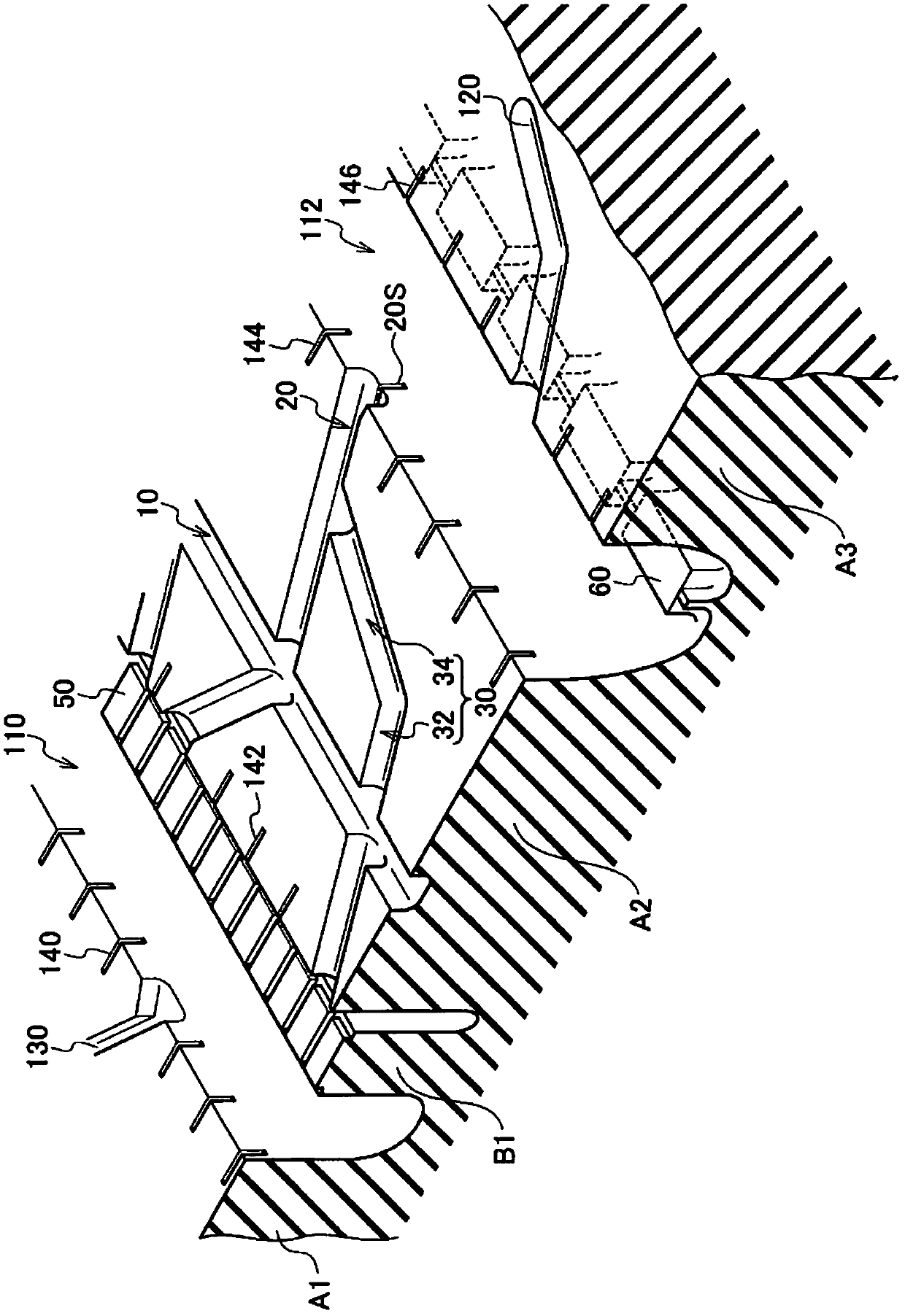

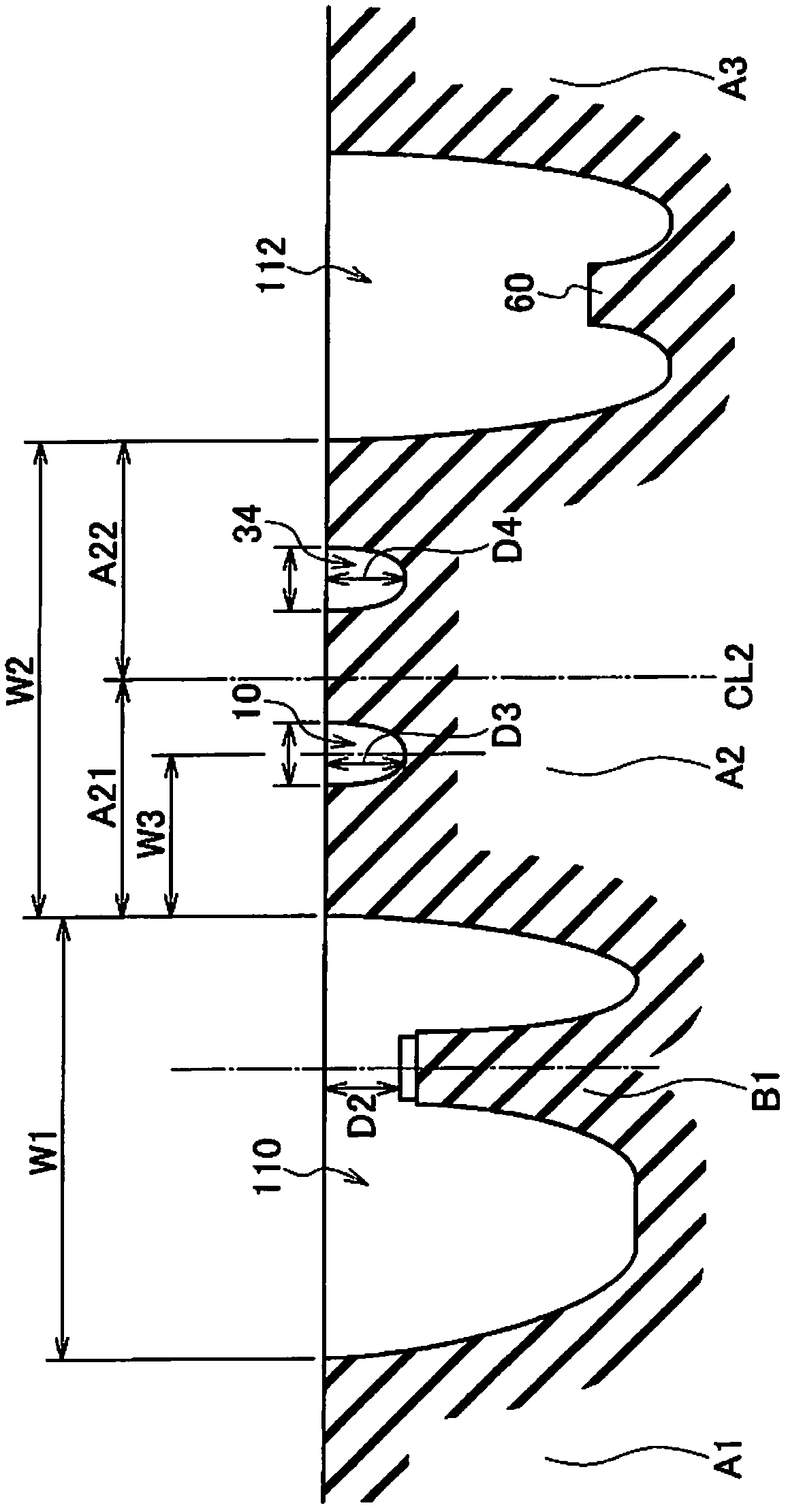

[0022] Next, embodiments of the heavy duty tire of the present invention will be described with reference to the drawings. In addition, in the description of the following drawings, the same or similar reference numerals are attached to the same or similar parts. However, it should be noted that the drawings are merely schematic representations, and ratios of dimensions and the like are different from actual ones.

[0023] Therefore, specific dimensions and the like should be determined with reference to the following description. In addition, it is needless to say that the relationship and ratio of mutual dimensions are different among the respective drawings.

[0024] In this embodiment, (1) the overall structure of the heavy-duty tire, (2) the detailed shape of the circumferential narrow grooves, (3) the detailed shape of the intersecting narrow grooves, (4) the detailed shape of the intersecting transverse grooves, (5) Modifications, (6) comparative evaluation, (7) actio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com