On-line rapid detection system for density of emulsion explosive semi-finished product

A technology of emulsion explosives and density detection, which is applied in the direction of measuring devices, specific gravity measurement, instruments, etc., can solve the problems of guidance lag, failure to consider errors, automatic sampling and other problems, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

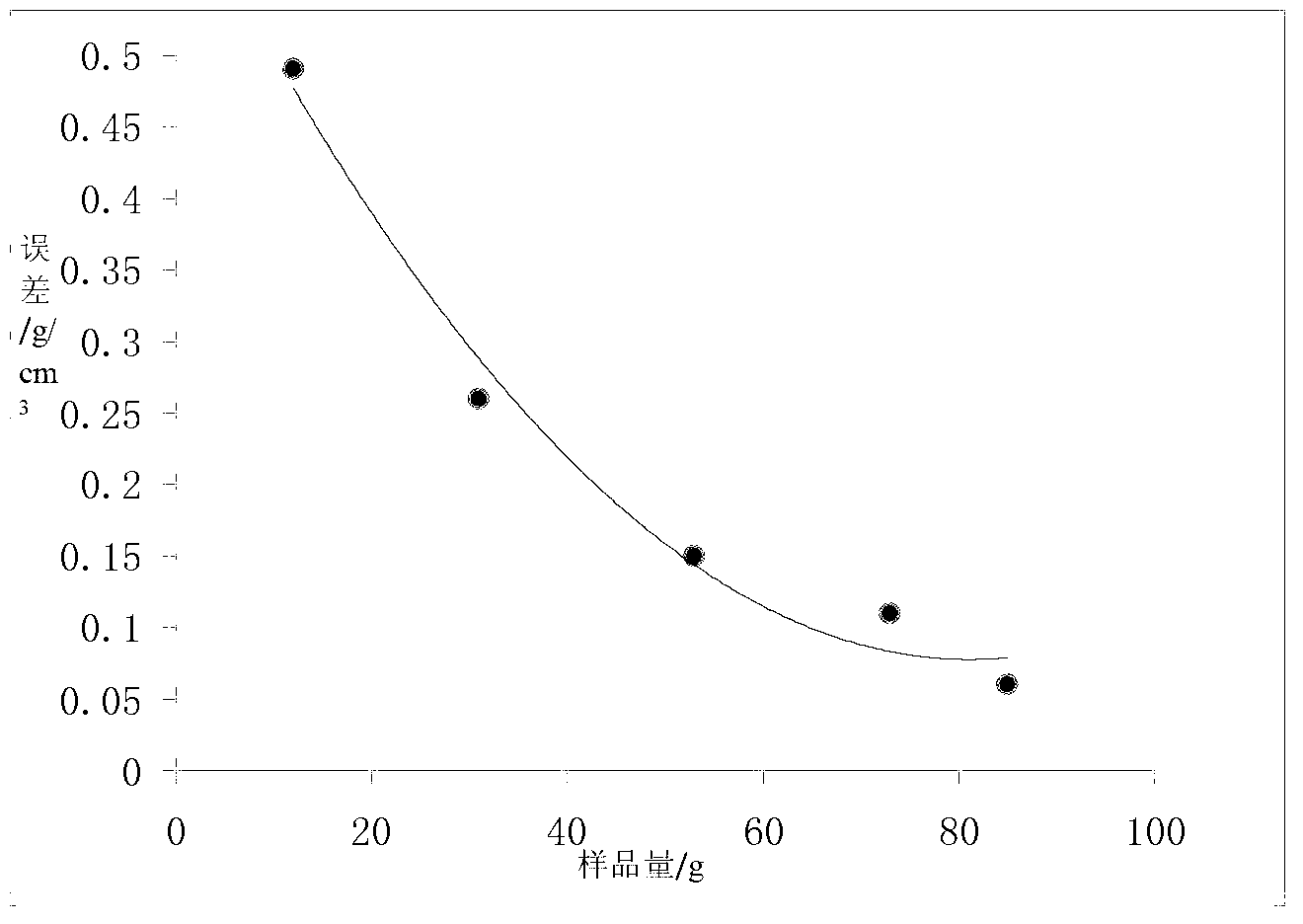

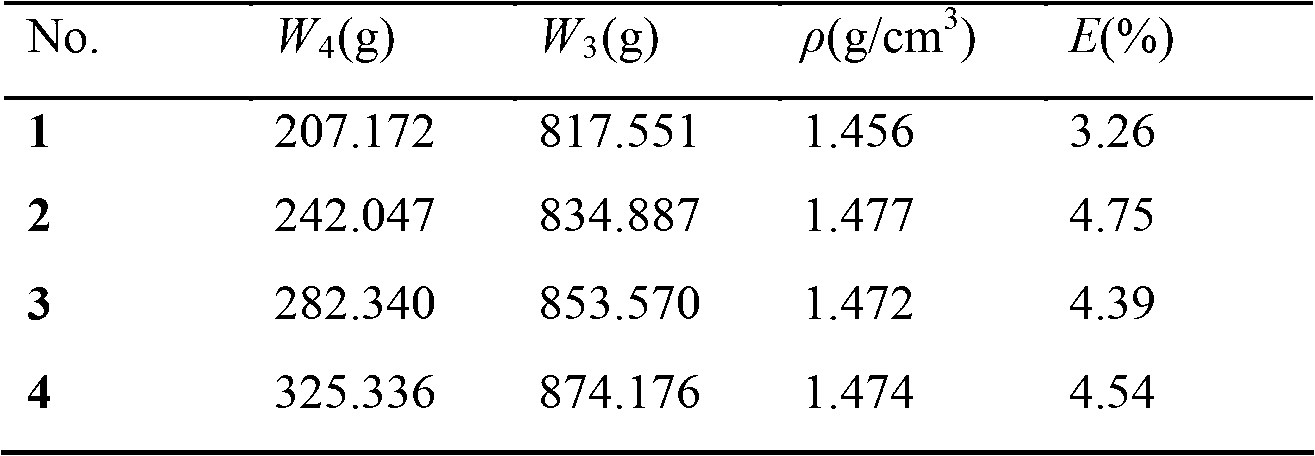

Embodiment 1

[0027] First, the control center 41 controls the solenoid valve unit 11 to open, and the sample outlet unit 12 takes out the sample, and enters the container filled with the solution on the first weighing device 21 through the sample delivery tube unit 13, and discharges the corresponding volume of the solution. into the empty container on the second weighing device 22 to measure the quality and volume of the sample; the weighing sensor is connected with the transmitter to convert the physical quantity into an analog signal, and the analog signal is converted into an available signal using the weighing signal conversion unit 31 Based on the digital signal of the density calculation unit 33, then execute the sample size judging unit 32, when the sample mass is greater than or equal to 86g, only execute the density calculation unit 33 to obtain the density detection value; the density calculation unit 33 utilizes the density calculation formula ρ=(W 3 +W 4 -W 1 -W 2 ) / (W 4 -W...

Embodiment 2

[0033] The invention is used to detect the density of steel with any shape to verify the universality of the density detection of the invention. First, directly put a certain amount of sample into the container full of solution on the first weighing device 21, and discharge the corresponding volume of solution into the empty container on the second weighing device 22 to measure the quality of the sample and volume; the weighing sensor is connected with the transmitter, and the physical quantity is converted into an analog signal, and the analog signal is converted into a digital signal that can be used for the density calculation unit 33 by using the weighing signal conversion unit 31, and then executes the sample size judging unit 32, when the sample When the quality is greater than or equal to 86g, only the density calculation unit 33 is executed to obtain the density detection value; the density calculation unit 33 utilizes the density calculation formula ρ=(W 3 +W 4 -W 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com