Sampling method for quality detection of entire top cover forging of reactor pressure vessel

A pressure vessel and quality inspection technology, applied in the direction of sampling devices, etc., can solve problems such as difficult inspection of the overall quality of forgings, difficulty in sampling non-standard sampling parts, and damage to joint parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

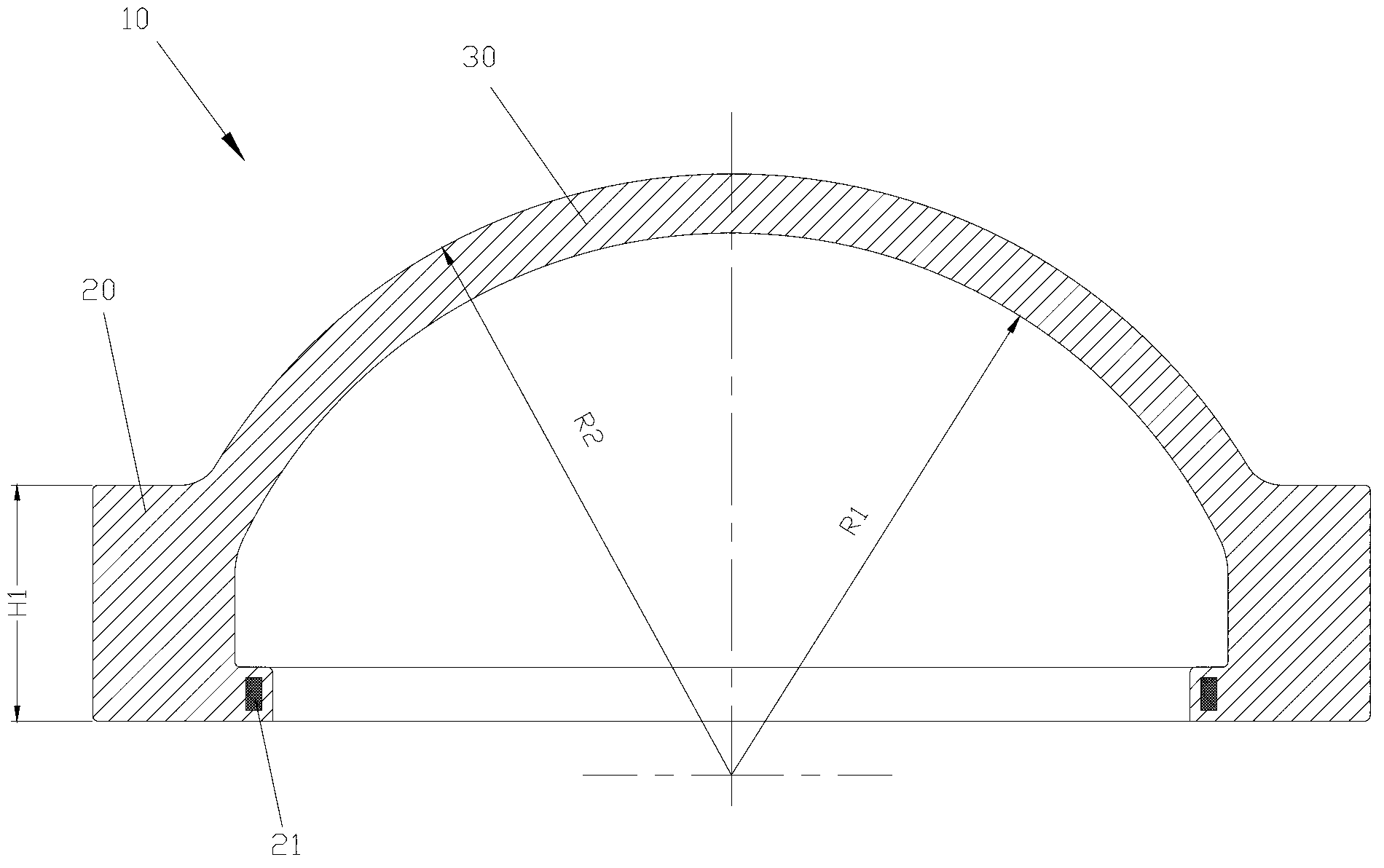

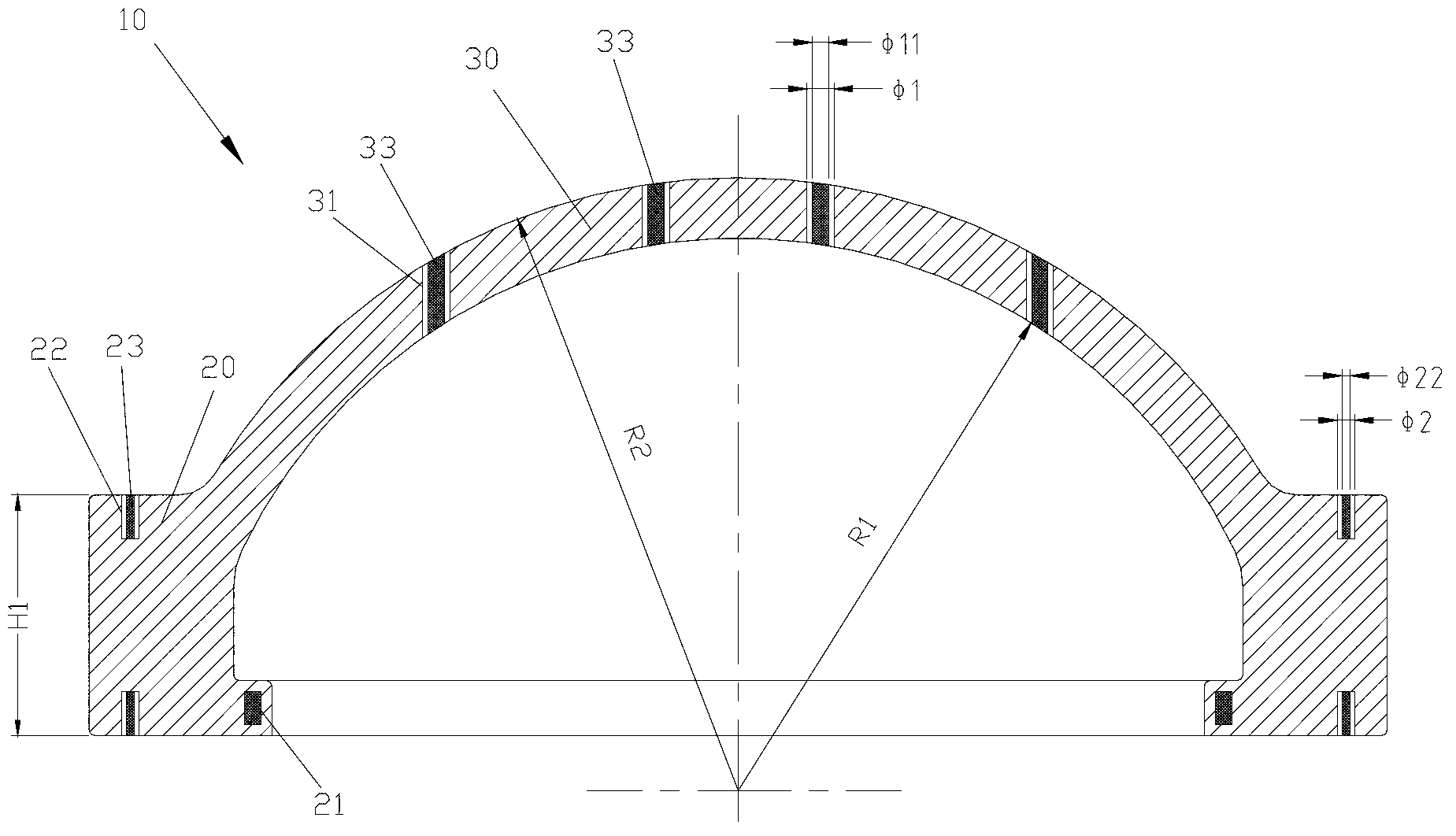

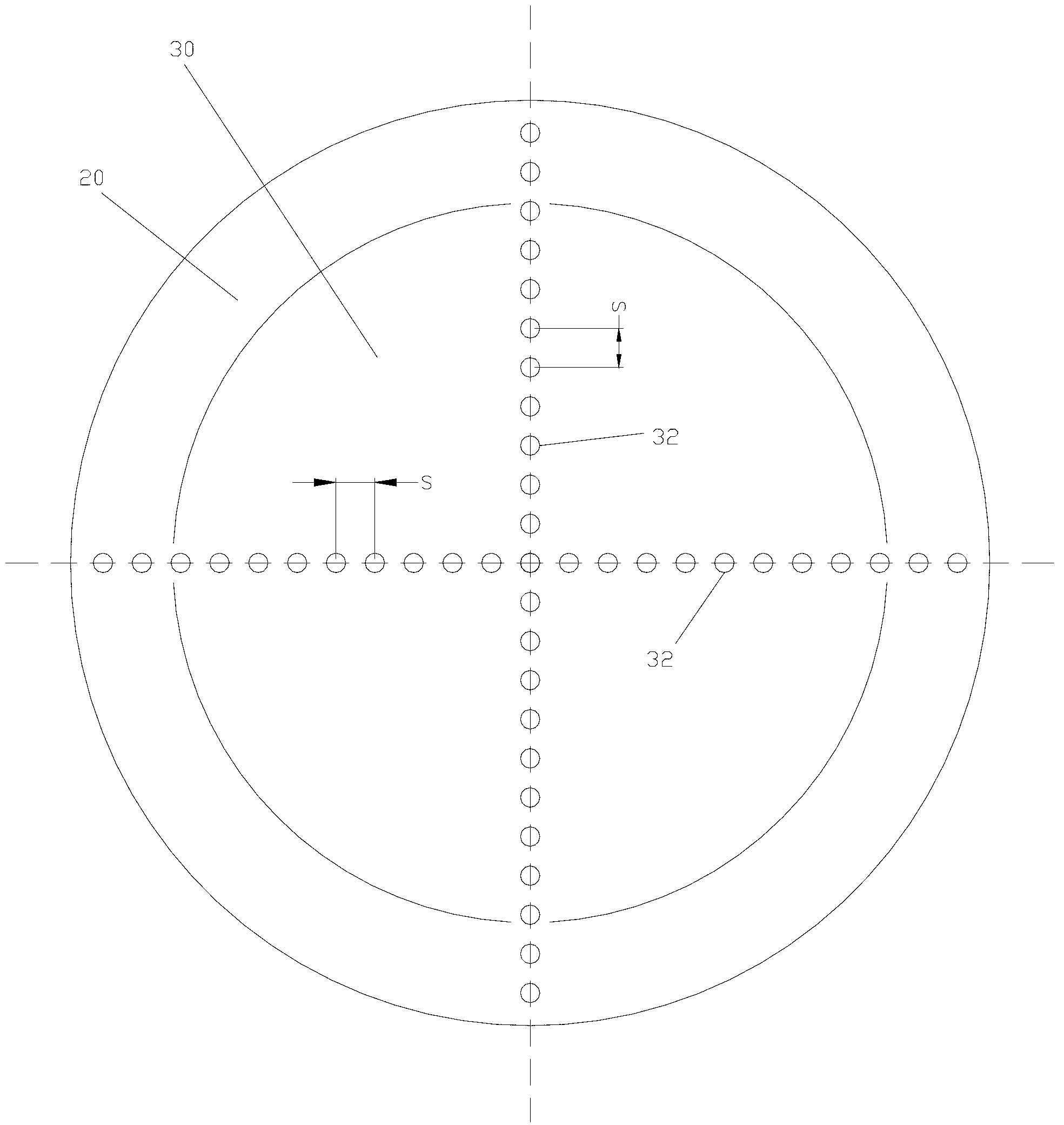

[0049] see Figure 1 to Figure 9 , The present invention provides a sampling method for the quality inspection of the integral top cover forging of a reactor pressure vessel. The integral top cover forging 10 includes a sealing portion 30 and a flange portion 20, and the integral top cover forging 10 has an integrally forged flange part 20 and a hemispherical sealing part 30, the flange part 20 is provided with an inner sample ring 21 at the lower part of the inner wall at the nozzle end. The height H of the flange part 20 1 =880mm, the inner radius of the head 30 is R 1 =2010mm, the outer radius is R 2 =2230mm. In addition, due to the installation needs of the integral roof forging 10, a plurality of installation holes for processing the installation holes 31 are preset on the head 30, and the diameter of the installation holes 31 is φ1=1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com