biomass stove

A technology for biomass stoves and hearths, which is applied to household stoves/stoves, stoves/stoves with hot water devices, and household cooking utensils. Complete combustion, low thermal efficiency of biomass stoves, etc., achieve good social benefits, complete combustion, and no slagging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

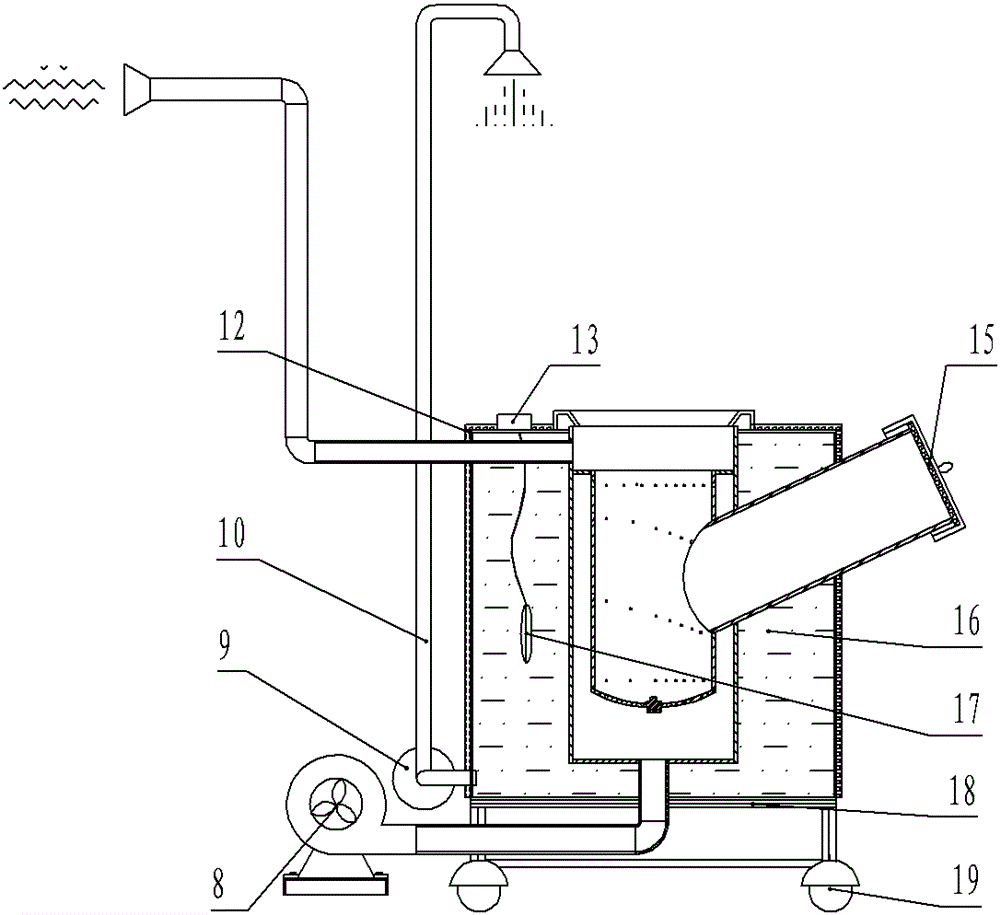

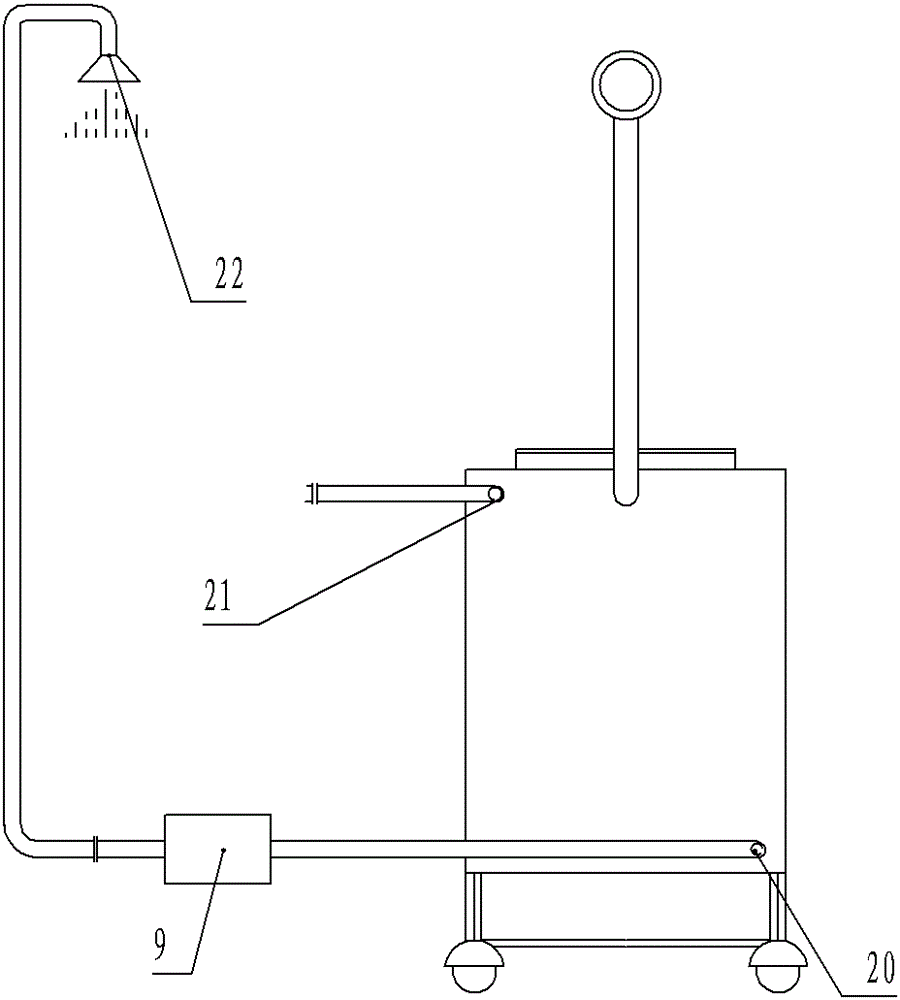

[0016] Such as figure 1 , figure 2 The biomass stove shown includes a stove frame 18 and a stove core. The bottom of the stove frame 18 is equipped with walking wheels 19; Water outlet 20 is provided; the top of water tank 16 is provided with exhaust hole 13, and micro-water pump 17 is housed in the water tank, and purpose is to make the water in the water tank be heated evenly; The insulation material is a ceramic fiber board; a stove core is inserted in the water tank 16, and in the present embodiment the water tank 16 is welded to the stove core; Adding fuel is more convenient.

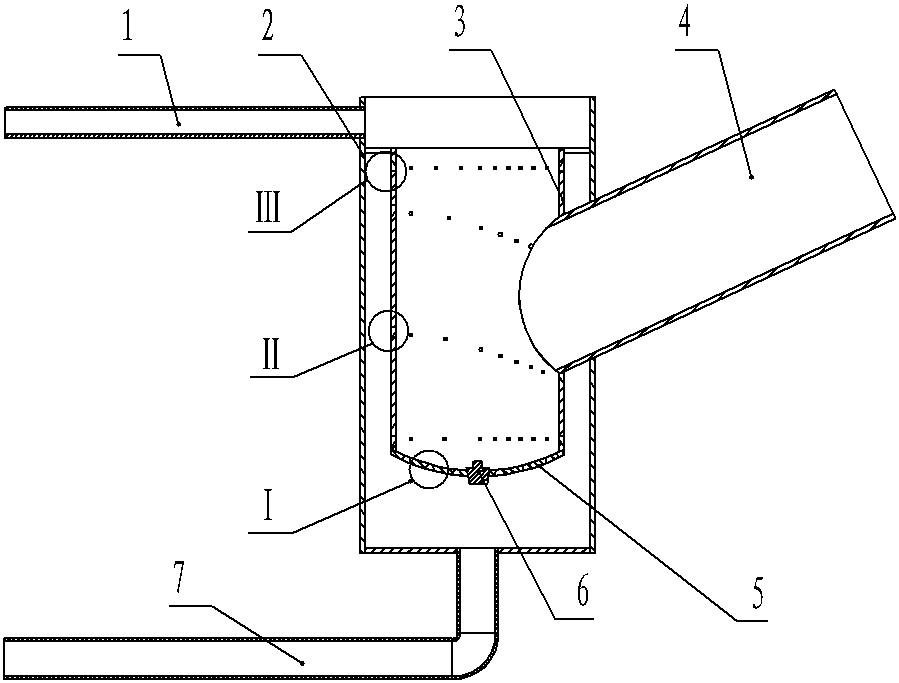

[0017] Such as image 3 The shown biomass stove core includes a stove chamber 3 and a stove cover 2 set outside the stove chamber 3, the gas supply chamber is between the stove chamber 3 and the stove jacket 2, and the tube wall of the stove chamber 3 is welded to one end of the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com