Retreating sectional type hydraulic cracking method

A hydraulic fracturing and segmented technology, applied in the field of hydraulic fracturing, can solve problems such as difficulty in meeting the effect of on-site hydraulic fracturing, easy blockage of gas migration channels, increase in gas content and pressure, etc. The effect of avoiding gas excess and improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

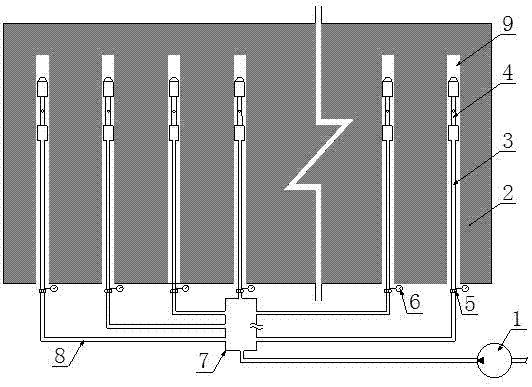

[0022] Embodiment one: The average thickness of the coal seam in a certain mine is about 2.51 m, and the buried depth is about 800 m. The coal seam is stable in occurrence and simple in structure. The inclination angle of the coal seam is about 0°-6°, with an average of 4°. It occurs in the middle and lower part of the Shanxi Formation, about 50 m away from the limestone at the top of the Carboniferous Taiyuan Formation, 36.6 m away from the sandstone at the bottom of the coal seam, and about 50 m away from the K 4 The aluminum mudstone is 51.51 m, the roof is sandy mudstone or sandstone, the floor is sandy mudstone and siltstone, and the coal seam is relatively stable. The gas content is about 11.15m 3 / t, gas drainage radius is 5 m, coal seam permeability coefficient is 0.0861 m 3 / (MPa 2 .d). The damage type of the coal seam belongs to the type III-IV coal, the relative gas pressure is 1.12-1.7 MPa, the firmness coefficient is 0.22-0.4059, the initial gas emission vel...

Embodiment 2

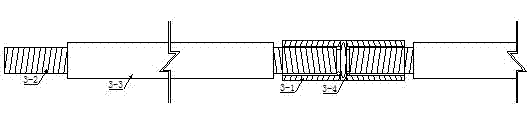

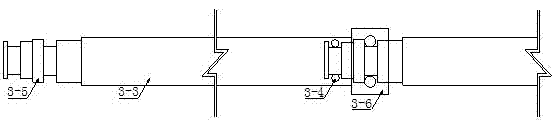

[0025] Embodiment two: The average thickness of the coal seam in a mine is 1.5 m, the average inclination angle is 6°, and the hardness of the coal seam f=2; the immediate roof is light gray medium-grained sandstone with an average thickness of 2.28 m; the old roof is gray-black sandy mudstone with an average thickness of 5.33 m. According to the actual situation on site, it is necessary to construct several hydraulic fracturing boreholes 9 with an inclination angle of 90°, linear, and vertical roof upward arrangement on the 30 m ahead of the working face of the wind tunnel, that is, the linear arrangement of the elevation angle. The diameter of the fracturing drilling is 32 mm, the hole depth is 4 m, and the drilling distance is 0.5 m. The construction is carried out along the advancing direction of the working face in sequence, and the directional cutting of the roof is carried out along the gob-side entry. A special fracturing installation rod 3 in the threaded connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com