Non-oriented electrical steel plate with extremely low content of Ti and smelting method for non-oriented electrical steel plate

A technology of oriented electrical steel sheets and oriented electrical steels, applied in the manufacture of converters, etc., can solve the problems of expensive modifiers, prolonging the smelting cycle, and complicated operation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with embodiment.

[0041] See Table 1 for the composition examples of the steel of the present invention, and see Table 1 for the steel composition examples. Table 2 is the performance of the steel of the embodiment. Wherein, A, B, and C represent different steel grades, and the embodiments and comparative examples can only be compared under the same steel grade.

[0042] The molten iron and steel scrap are matched according to the proportion. After smelting in a 300-ton converter, controlling the slag during the tapping process, RH refining decarburization, weak deoxidation, and alloying of ferrosilicon and ferromanganese, and then continuous casting, the final 170-250mm thick, 800 ~1400mm wide continuous casting slab.

[0043] Table 1 Unit: weight percentage

[0044]

[0045] Table 2

[0046]

[0047]

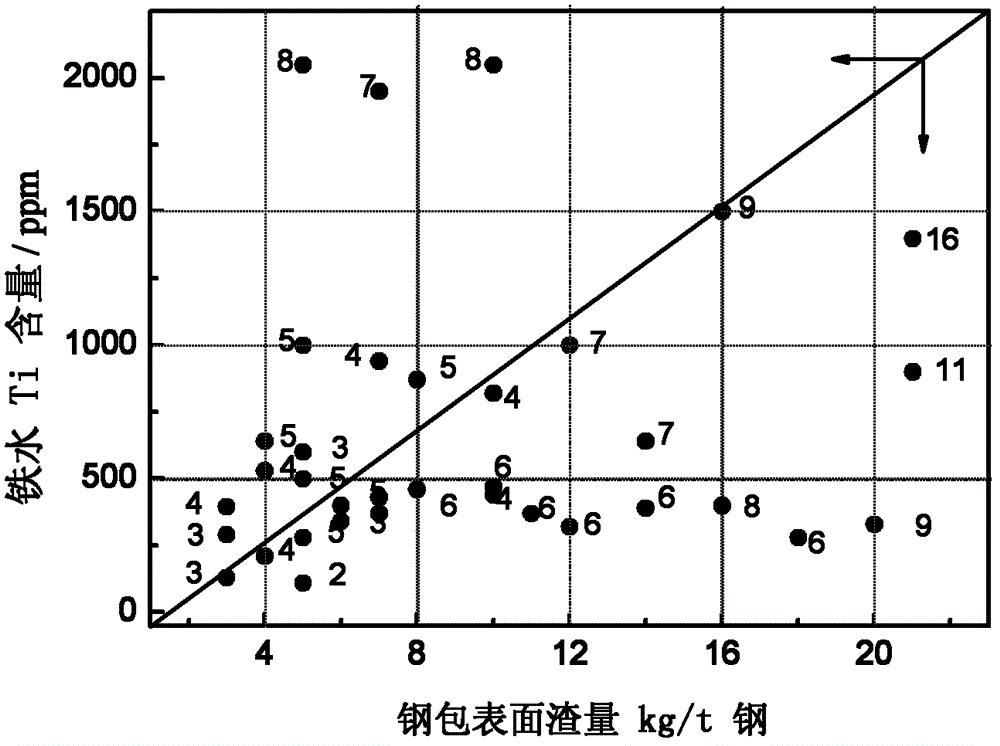

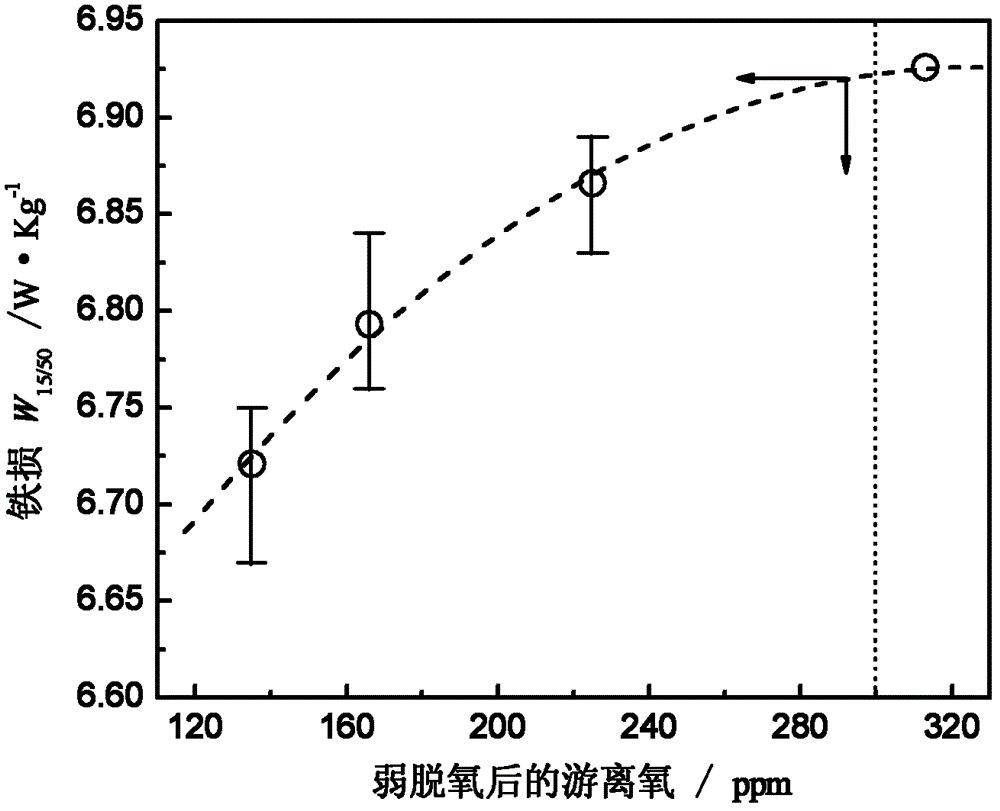

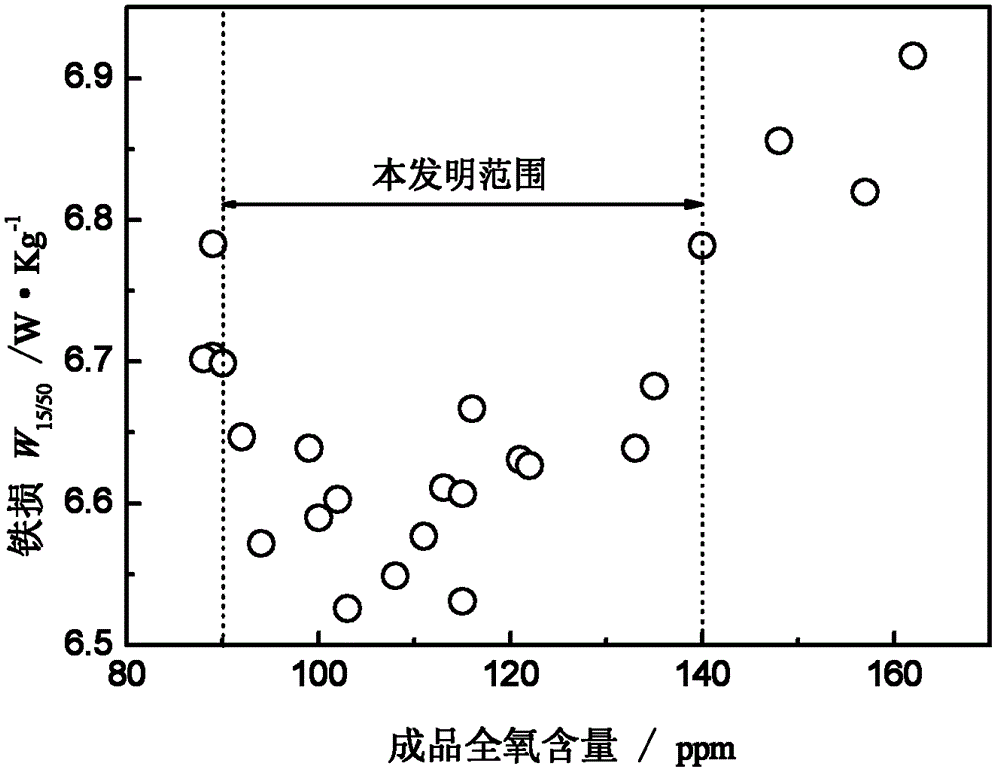

[0048] It can be seen from Table 2 that the amount of slag discharged from the conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com