Technology of desulphurization by regenerated ammonia with combined production of calcium sulfate whisker

A calcium sulfate whisker and process technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of low product whiteness, uneven aspect ratio, high production cost, etc., and achieve reduced wear and high Product value, effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

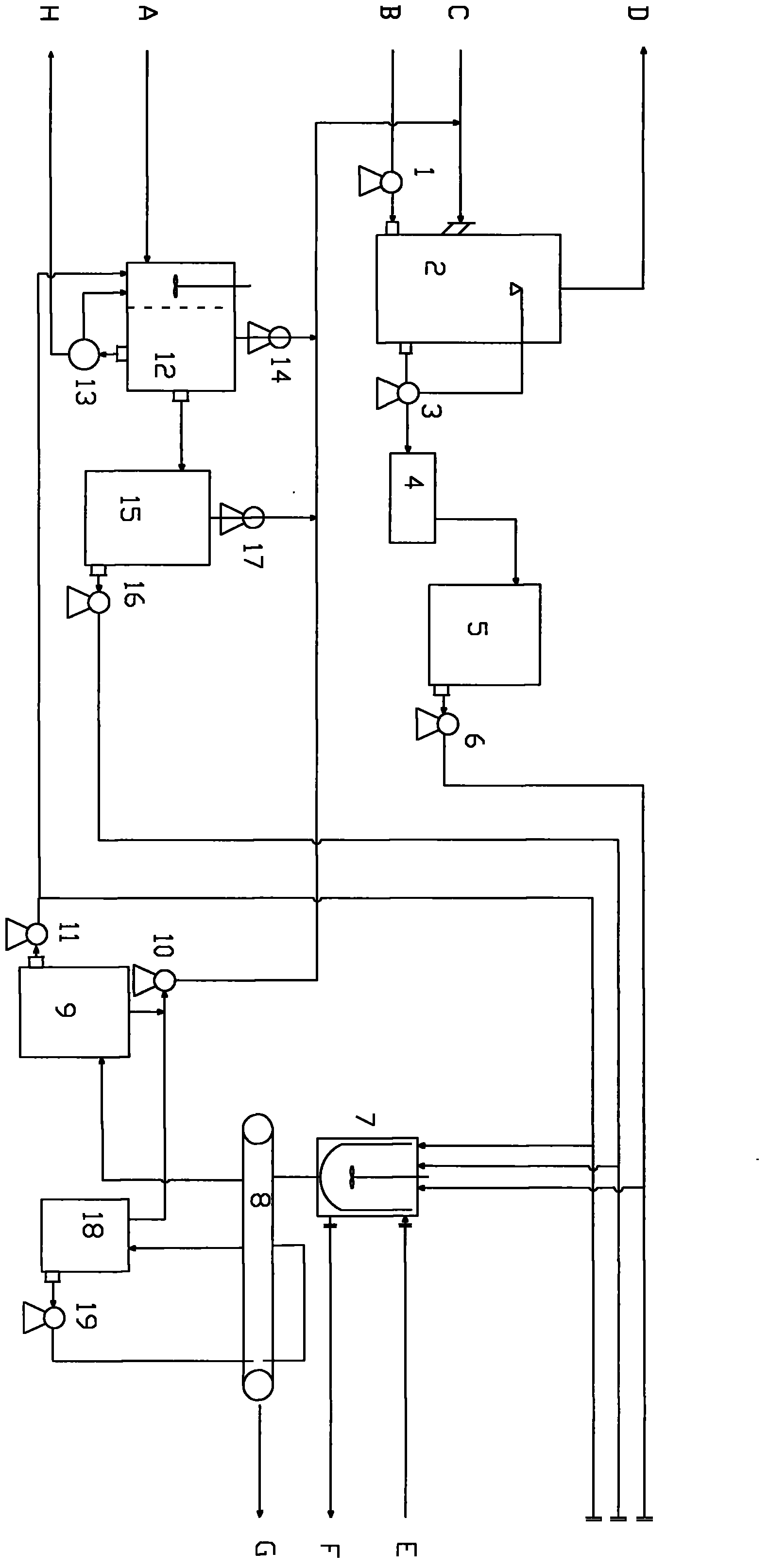

[0022] figure 1 Medium oxidation fan 1, desulfurization absorption tower 2, slurry circulation pump 3, filter 4, ammonium sulfate liquid tank 5, ammonium sulfate liquid pump 6, whisker reactor 7, mesh belt filter 8, ammonium chloride liquid tank 9, Vacuum pump 10, ammonium chloride liquid pump 11, ammonia regeneration tank 12, centrifugal filter 13, induced draft fan 14, calcium chloride liquid tank 15, calcium chloride liquid pump 16, leaf filter vacuum pump 17, washing liquid tank 18, washing liquid Pump 19; calcium carbide mud A, desulfurization slag B, oxidizing air C, flue gas D, purified flue gas E, steam F, condensed water G, gypsum whiskers H, and sludge I.

[0023] The flow rate is 600000Nm 3 / h, the flue gas D with a temperature of 150°C enters the middle part of the desulfurization absorption tower 1, and is in countercurrent contact with the circulating slurry sprayed from the upper part. The slurry in the tower is circulated by the slurry circulating pump 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com