Multi-tensioning belt filter press

A filter press and tight-belt technology, applied in the field of dehydration equipment, can solve problems such as affecting the dehydration efficiency of the equipment, affecting the dehydration effect of the equipment, separating the cleaning water from the filter belt, etc. The effect of moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

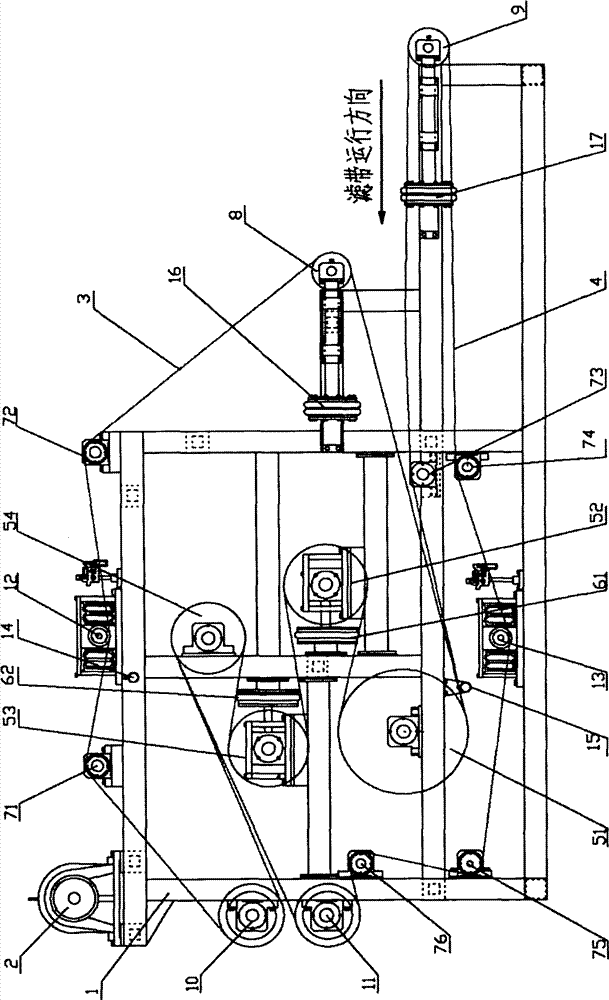

Embodiment 1

[0033] Such as figure 1As shown, a multi-tension belt type filter press includes a driving device 2 on a frame 1, an upper filter belt 3, a lower filter belt 4, an upper filter belt tension roller 8, a lower filter belt tension roller 9, Upper filter belt drive roller 10, lower filter belt drive roller 11, pressure roller set, guide roller set, upper filter belt deflection adjustment roller 12, lower filter belt deflection adjustment roller 13, upper filter belt cleaning water pipe 14, lower filter belt cleaning water pipe 15, upper filter belt tensioning device 16, lower filter belt tensioning device 17. Pressure rollers 51, 52, 53, 54 are arranged in the pressure roller group, and guide rollers 71, 72, 73, 74, 75, 76 are arranged in the guide roller group. Tensioning devices 61 and 62 are respectively installed on the pressure rollers 52 and 53 in the pressure roller group. When the belt filter press is running, the upper filter belt tensioning device 16 applies the tensio...

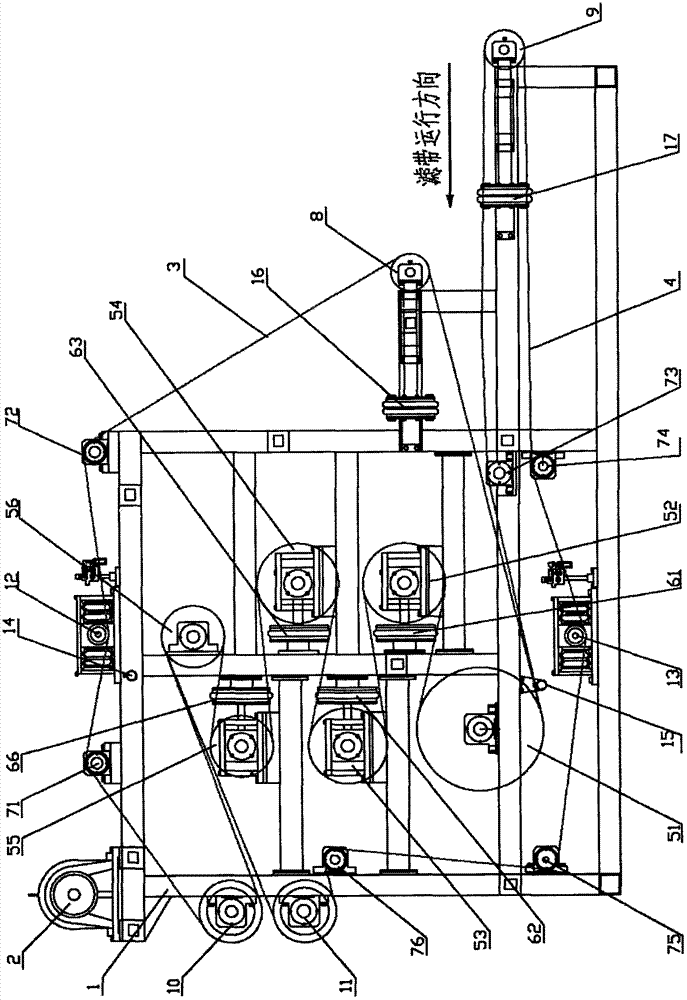

Embodiment 2

[0035] Such as figure 2 As shown, in order to increase the time for the material to be squeezed and further reduce the water content of the filter cake after the material is press-filtered, it is also possible to increase the pressure rollers in the pressure roller set on the basis of Embodiment 1, that is, the pressure rollers 51, 52 , 53, 54, 55, 56, in order to compensate for the pressure loss on the pressure rollers, tensioning devices can be installed on two of them, that is, tensioning devices 62 and 63 are installed on the pressure rollers 53,54. Tension devices can also be installed on four of the pressure rollers, that is, tension devices 61 , 62 , 63 and 64 are respectively installed on the pressure rollers 52 , 53 , 54 , and 55 .

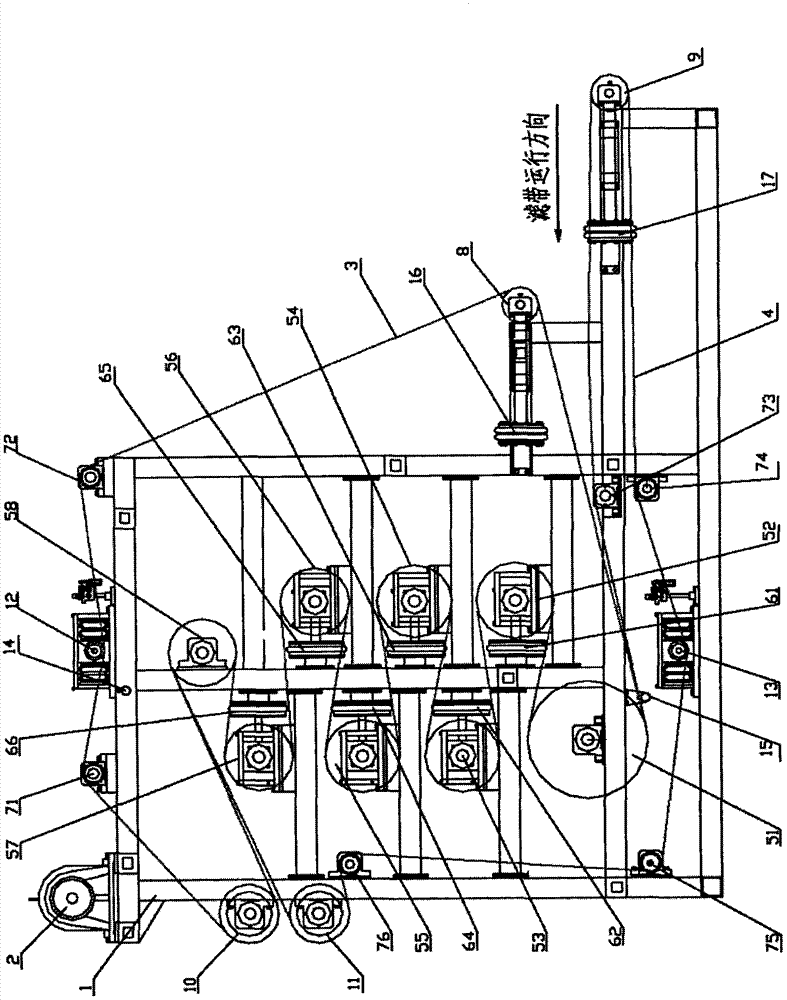

Embodiment 3

[0037] Such as image 3 As shown, in order to further increase the time for the material to be extruded, the moisture content of the filter cake after the material is press-filtered is lower, and the pressure rollers in the pressure roller group can also be increased to eight on the basis of the first and second examples. , namely pressure rollers 51, 52, 53, 54, 55, 56, 57, 58. In order to compensate for the loss of extrusion force on the pressure rollers, tensioning devices can be installed on six of the pressure rollers, that is, tensioning devices 61, 62, 63, 64, 65 and 66.

[0038] The upper filter belt cleaning water pipe 14 is installed between the upper filter belt deflection adjustment roller 12 and its previous guide roller 71 or the next guide roller 72, below the upper filter belt 3, and sprays water from bottom to top on the upper filter belt. 3 for cleaning. The lower filter belt cleaning water pipe 15 is installed between the lower filter belt deflection adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com