A kind of preparation method of tofu skin

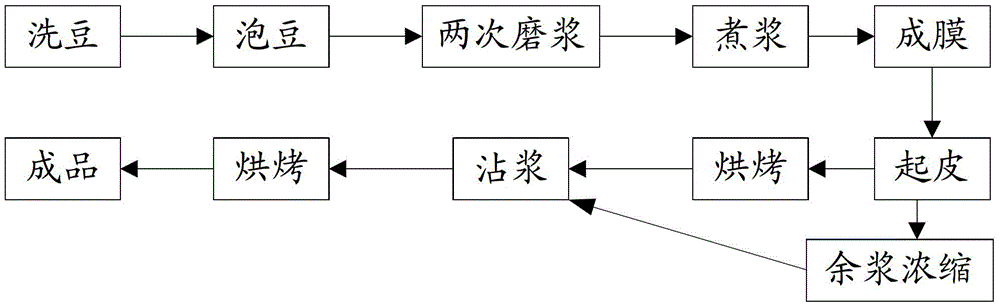

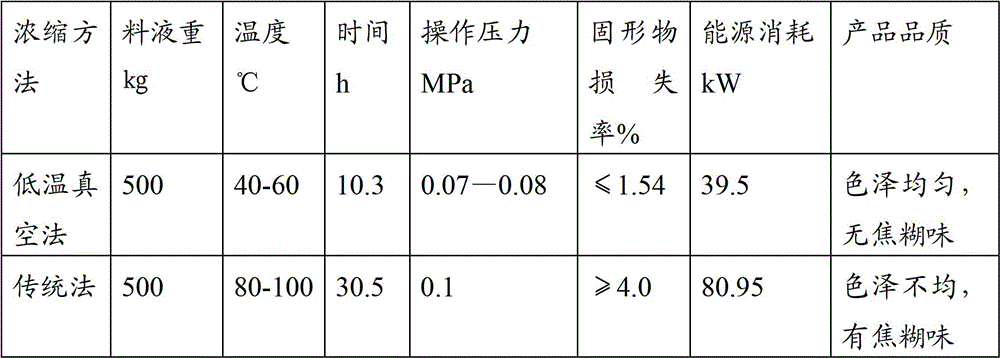

A production method and a technology for tofu skin are applied in the field of preparation of bean products, which can solve the problems of waste of remaining soybean milk, unhealthy health, and deep luster of tofu skin, so as to shorten the film-forming time, save energy consumption, and optimize the cooking time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Make bean curd skin specifically as follows with the manufacture craft of above-mentioned bean curd skin:

[0071] (1) Steps 1-4 of the manufacturing process of tofu skin as described above to obtain homogeneous soybean milk:

[0072] (2) Boil the milk: heat the raw soybean milk obtained in the above (1) at 90°C under sealed conditions for 10 minutes;

[0073] (3) Conjunctiva: control step (2) temperature of soybean milk to 78°C, blowing air to make conjunctiva on the surface of soybean milk;

[0074] (4) Remove the film: use 0.1M sodium hydroxide to control the pH value of the soy milk to 7.0, and remove the tofu skin;

[0075] (5) Concentration: Place the remaining soybean milk in step (4) in a three-effect vacuum concentration and vacuum scraper concentration system at a temperature of 50°C and a vacuum degree of 0.07MPa to vacuum concentrate to a slurry specific gravity of 1.4;

[0076] (6) Dipping: put the tofu film obtained in step (4) at 55°C, bake for one hour...

Embodiment 2

[0080] Make bean curd skin specifically as follows with the manufacture craft of above-mentioned bean curd skin:

[0081] (1) Steps 1-4 of the manufacturing process of tofu skin as described above to obtain homogeneous soybean milk:

[0082] (2) Boil the milk: heat the raw soybean milk obtained in the above (1) at 93°C under sealed conditions for 13 minutes;

[0083] (3) Conjunctiva: control step (2) temperature of soybean milk to 80°C, blowing air to make conjunctiva on the surface of soybean milk;

[0084] (4) Remove the film: use a tofu skin rod to stir up the tofu skin, and control the pH of the soy milk to 6.5;

[0085] (5) Concentration: Place the remaining soybean milk in step (4) in a three-effect vacuum concentration and vacuum scraper concentration system at a temperature of 55°C and a vacuum degree of 0.07 for 10.3 hours until the slurry has a specific gravity of 1.3;

[0086] (6) Dipping: Bake the tofu film obtained in step (4) at a low temperature of 55°C for on...

Embodiment 3

[0090] Make bean curd skin specifically as follows with the manufacture craft of above-mentioned bean curd skin:

[0091] (1) Steps 1-4 of the manufacturing process of tofu skin as described above to obtain homogeneous soybean milk:

[0092] (2) Boiling: heat the raw soybean milk obtained in (1) above in a sealed tank at 95°C for 15 minutes;

[0093] (3) Conjunctiva: control step (2) Soymilk temperature to 80±2°C, blowing air to make conjunctiva on the surface of soymilk;

[0094] (4) Remove the film: use a tofu skin rod to stir up the tofu skin, and control the pH value of the soy milk to 7.0;

[0095] (5) Concentration: Place the remaining soybean milk in step (4) in a three-effect vacuum concentration and vacuum scraper concentration system at a temperature of 60°C and a vacuum degree of 0.08MPa for 14 hours until the slurry has a specific gravity of 1.4;

[0096] (6) Dipping: Bake the tofu film obtained in step (4) at 60°C for one hour, remove the surface moisture, remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com