Disc-type permanent magnet motor with sealed cooling structure

A permanent magnet motor and cooling structure technology, applied in electric components, cooling/ventilation devices, electromechanical devices, etc., can solve the problems of winding temperature rise, motor burning, permanent magnet corrosion, etc., to increase the heat dissipation area and ensure cooling effect, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

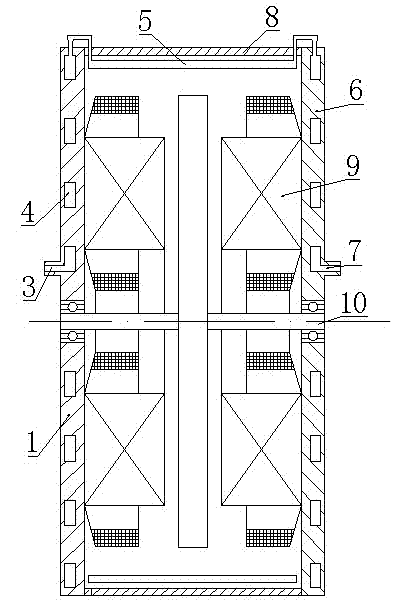

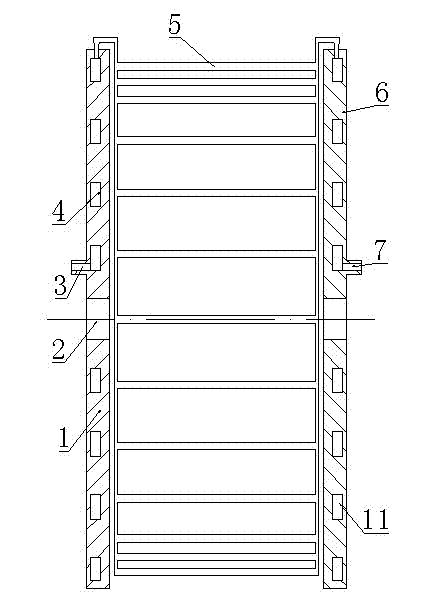

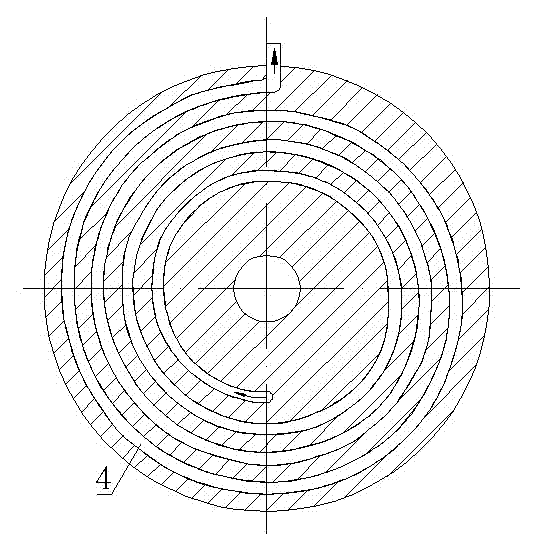

[0024] As shown in the figure, the disc permanent magnet motor with a closed cooling structure includes a casing 8, a driving side end cover 1 and a non-driving side end cover 6 arranged on both sides of the casing 8, and the driving side end cover 1 and the non-driving side The center of the end cover 6 is respectively provided with a shaft hole 2, and windings 9 are respectively installed on the driving side end cover 1 and the non-driving side end cover 6, and the two windings 9 are respectively the driving side winding and the non-driving side winding. A rotating shaft 10 is arranged between the holes 2 . In the end cover 1 on the driving side and the end cover 6 on the non-driving side, a spiral end cover water channel I4 and an end cover water channel II11 are respectively provided, and the rotation directions of the end cover water channel I4 and the end cover water channel II11 are opposite. In this embodiment , the rotation direction of the end cap water channel I4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com