Preparation method and application of electrode sheet

A technology of electrode sheet and conductive agent, which is applied in the field of electronics, can solve the problems of high brittleness and easy breakage of electrode sheets, and achieve the effects of improved liquid absorption, improved flexibility, and excellent conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

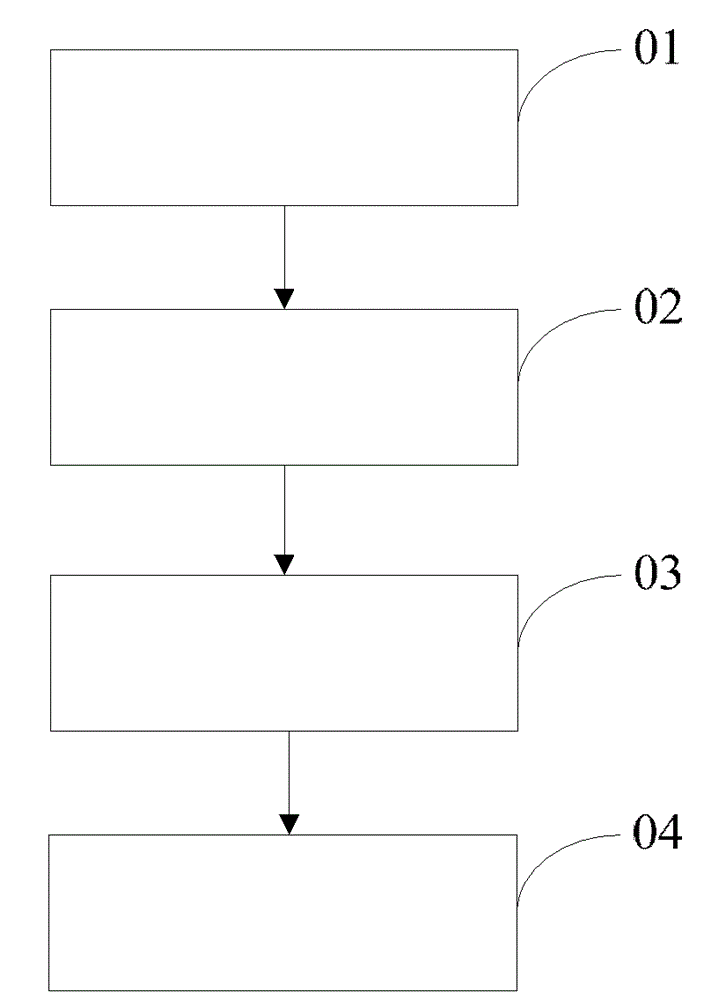

[0022] see figure 1 , figure 1 A flow chart showing a method for preparing an electrode sheet according to an embodiment of the present invention includes the following steps:

[0023] S01, respectively provide activated carbon, conductive agent, carboxymethyl cellulose and binder, the mass percentage of the activated carbon is 60-80%, the mass percentage of conductive agent is 10-30%, carboxymethyl cellulose The mass percentage of the binder is 0.5-5%, and the mass percentage of the binder is 5-10%;

[0024] S02, mixing activated carbon, conductive agent and carboxymethyl cellulose to obtain the first mixture;

[0025] S03, mixing the binder and water to obtain a second mixture;

[0026] S04, under the stirring condition, mix the first mixture and the second mixture, let stand for 2-8 hours, dry, and press to form an electrode sheet.

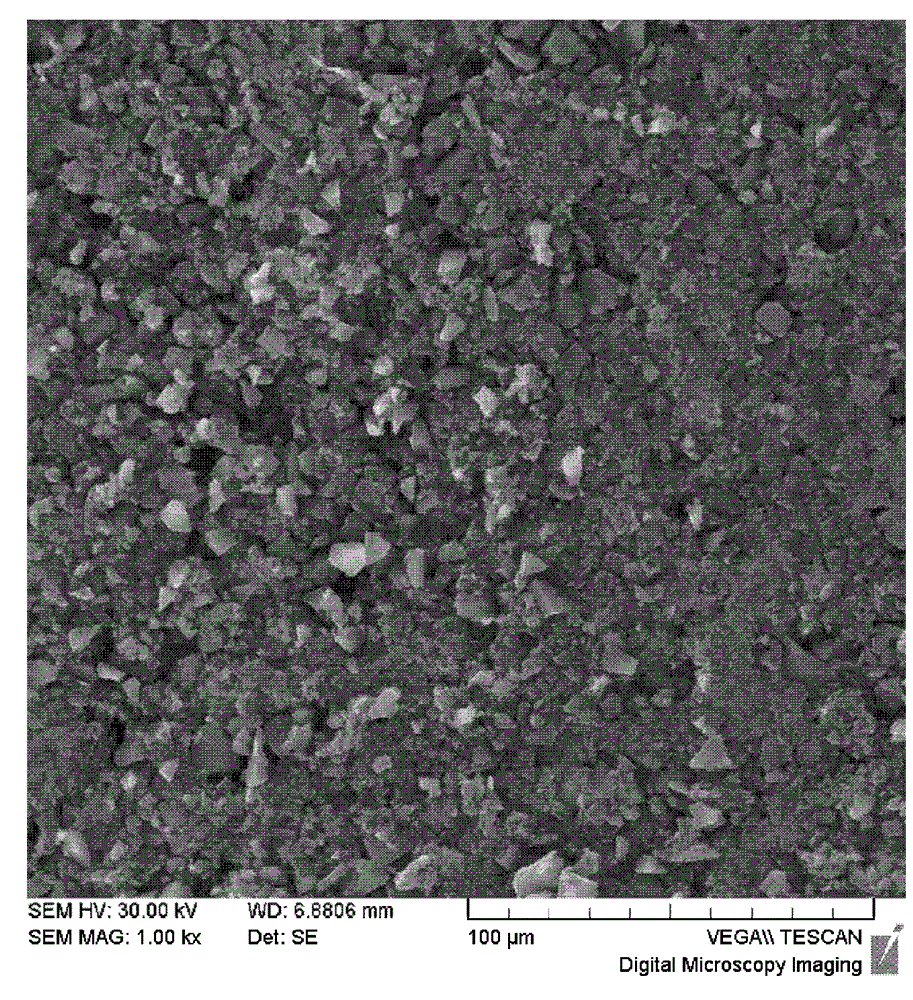

[0027] Specifically, in step S01, the activated carbon is in the form of powder, the particle size is 0.5-10 μm, and the mass percentage o...

Embodiment 1

[0038] The gac that mass percent composition is 65% is provided respectively, and mass percent composition is 24.5% conductive agent, and mass percent composition is 0.5% carboxymethyl cellulose, and mass percent composition is 10% binding agent (total amount 50g);

[0039] The activated carbon, conductive agent and carboxymethyl cellulose were added to the stirrer and stirred for 2 hours to obtain the first mixture;

[0040] The adhesive was added into 100g of water, and stirred for 1.5h to obtain the second mixture;

[0041] Add the second mixture to the mixer, stir for 2 hours, and then stand for emulsification for 2 hours; put it in a blast drying oven and dry it at 100°C for 6 hours to obtain the electrode sheet precursor; use the electrode sheet precursor The electrode sheet is formed by machine pressing, and the thickness of the electrode sheet is 0.4mm.

[0042] Preparation of supercapacitors:

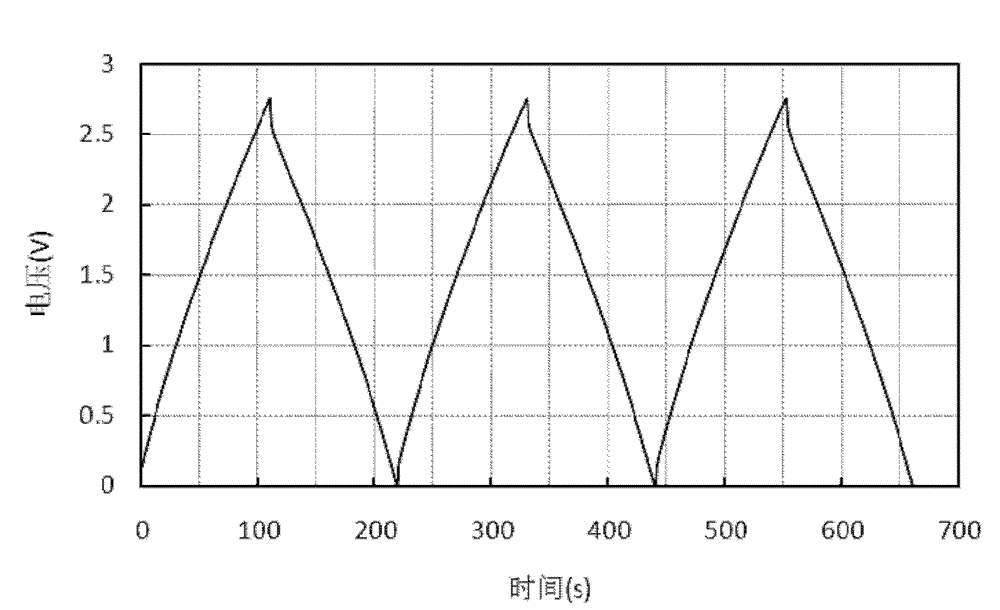

[0043] Put the electrode sheet and diaphragm into the stainless steel s...

Embodiment 2

[0046] The gac that is 75% by mass percentage is provided respectively, the conductive agent that is 15% by mass percentage, carboxymethyl cellulose that is 5% by mass percentage, and the binding agent that is 5% by mass percentage (total amount 50g);

[0047] The activated carbon, conductive agent and carboxymethyl cellulose were added to the stirrer and stirred for 2.5 hours to obtain the first mixture;

[0048] The adhesive was added into 200g of water, and stirred for 1h to obtain the second mixture;

[0049]Add the second mixture to the mixer, stir for 2.5 hours, and then stand for emulsification for 4 hours; put it in a blast drying oven and dry it at 100°C for 8 hours to obtain the electrode sheet precursor; use the electrode sheet precursor The electrode sheet is formed by machine pressing, and the thickness of the electrode sheet is 0.4mm.

[0050] Preparation of supercapacitors:

[0051] Put the electrode sheet and diaphragm into the stainless steel shell, inject ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com