Sampler for taking samples from melts having a melting point higher than 600c, and method for taking samples

A technology of sampling device and melt, which is applied in the direction of sampling device, measuring device, sampling, etc., and can solve the problem of damage to the sample cavity at the immersion end of the carrying tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

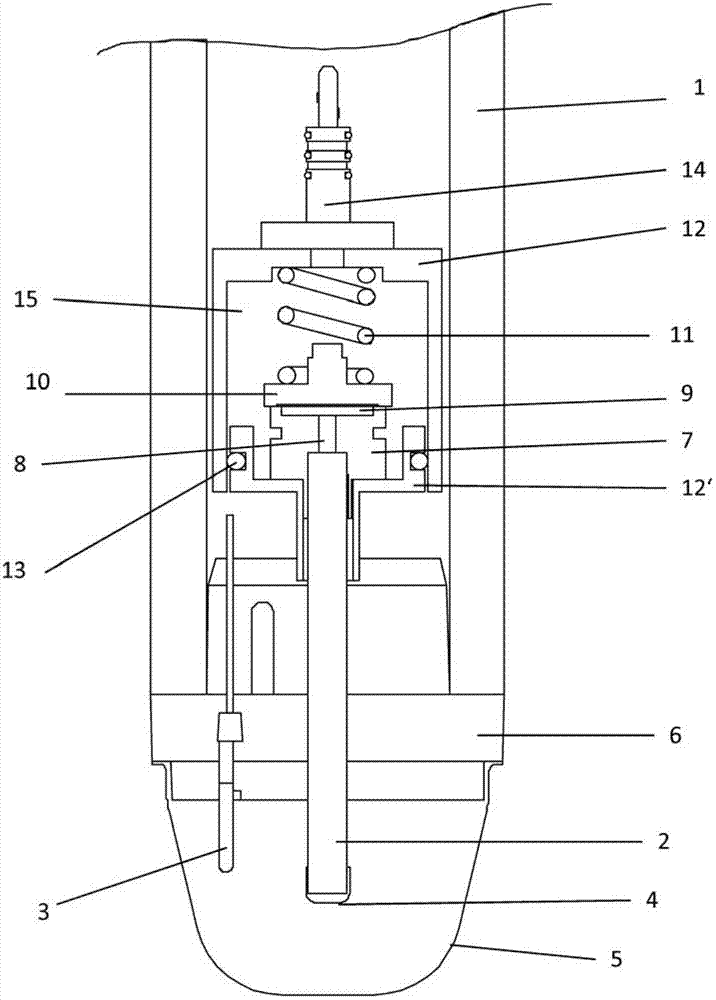

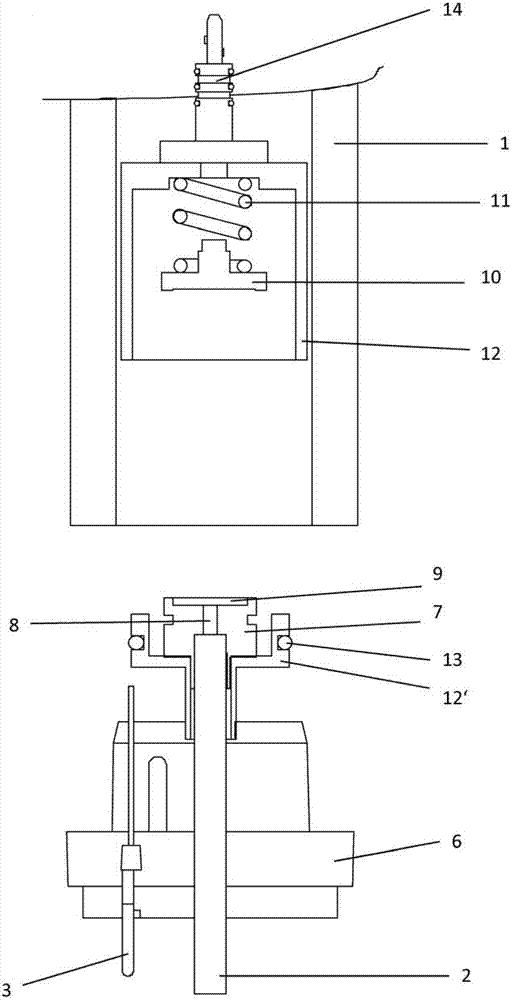

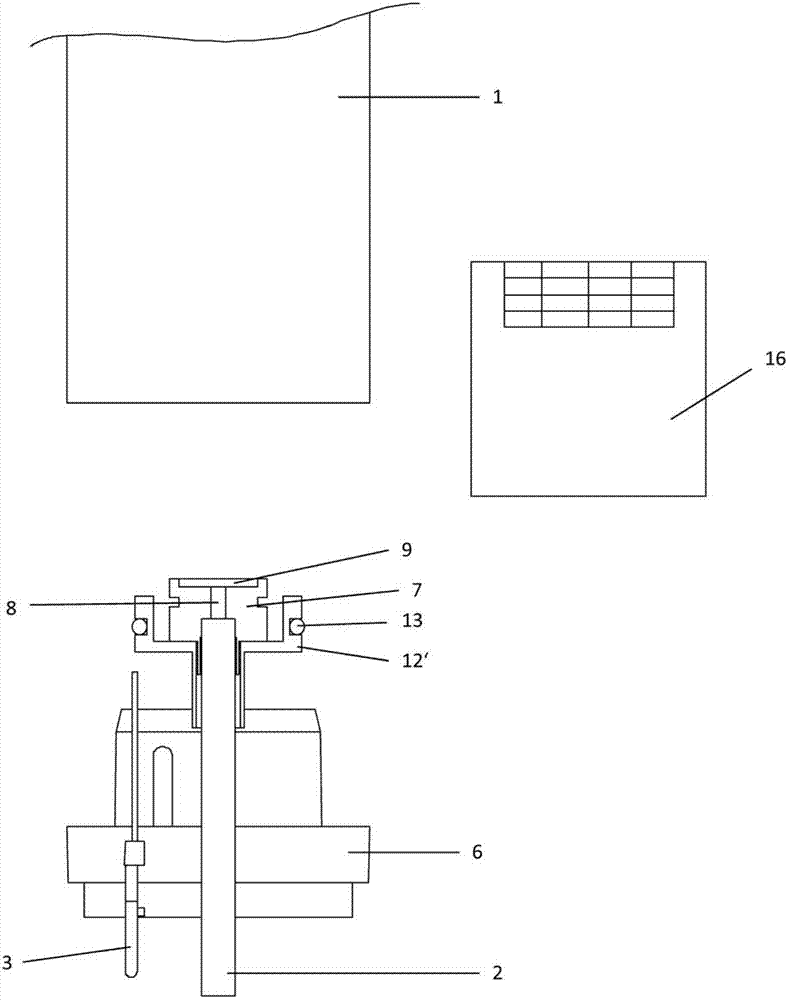

[0046] figure 1 A cutaway view of the submerged end of the sampling device is shown. The input pipe 2 and the thermal sensor 3 of the molten metal sample are exposed at the immersion end of the carrying pipe 1 . The metal cap 4 protects the input pipe 2 . The metal cap 4 and the outer protective cap 5 made of metal prevent the inlet pipe 2 from being damaged during conveyance and prevent the inlet pipe 2 from immersing in the metal melt (e.g. steel melt) when the sampling device passes through the slag layer Afterwards, but before the opening of the inlet tube 2 is exposed, it is damaged. The thermosensitive element 3 and the input pipe 2 are fixed on the heat-resistant body 6 . The inlet pipe 2 leads into the cooling body 7 , and the molten metal passes through the passage opening 8 of the cooling body into the sample chamber 9 . The upper side of the sample chamber (viewed in the immersion direction) is closed off by an upper cooling body 10 . The cooling bodies 7, 10 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com