Adjustable molding equipment for H-steel corrugated web plate

A corrugated web, forming equipment technology, applied in the field of corrugated web adjustable forming equipment, can solve the problems of inconvenience, time-consuming, labor-consuming and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

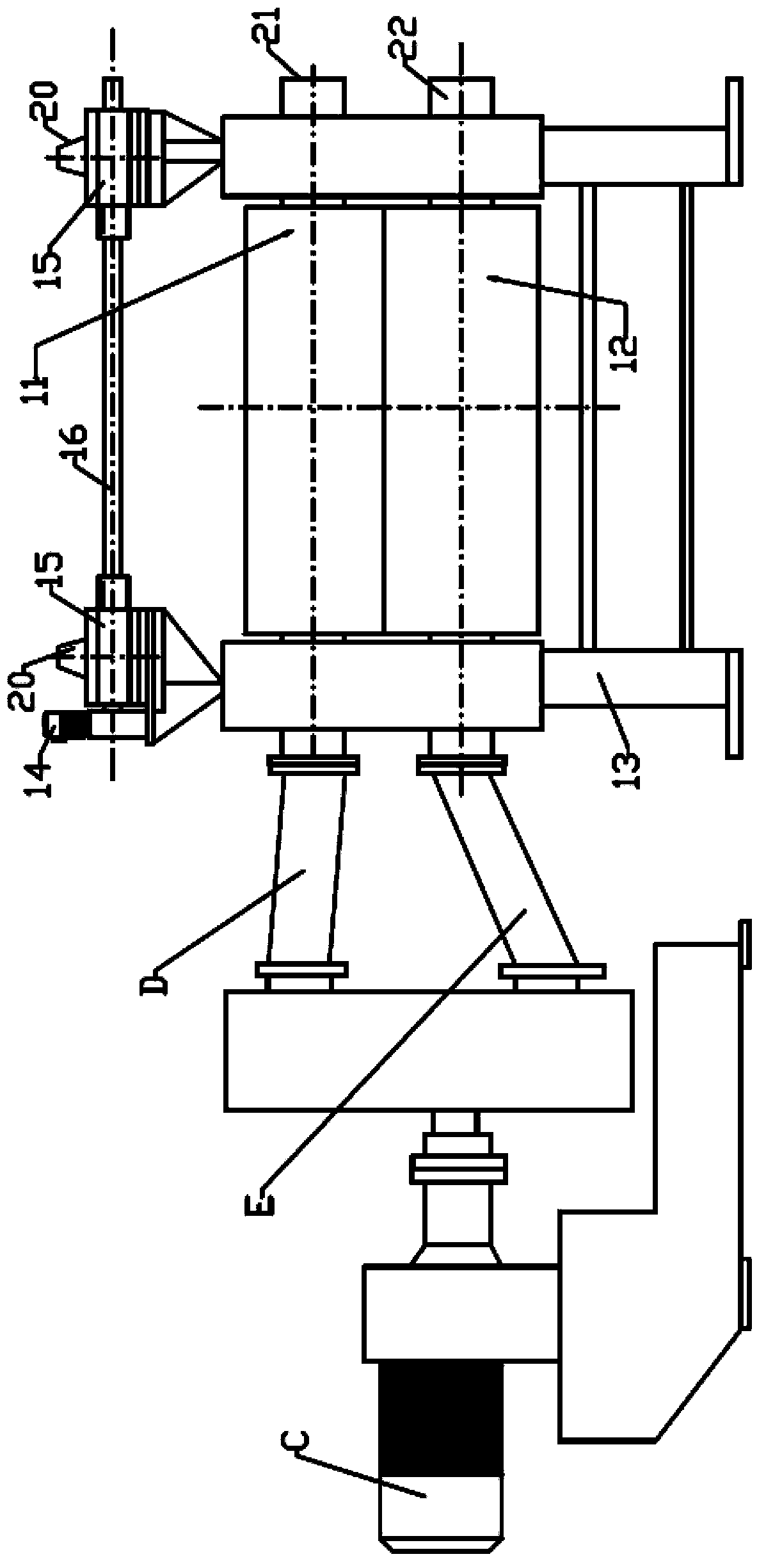

[0019] The power system of the forming equipment of the present invention has a driving motor C, which is respectively connected to the central shafts of the upper and lower forming rollers through two universal couplings D and E, and is arranged on the frame 13 to drive the upper forming roller 11 at the same time. And the lower forming roller 12 rotates at a constant speed in the opposite direction.

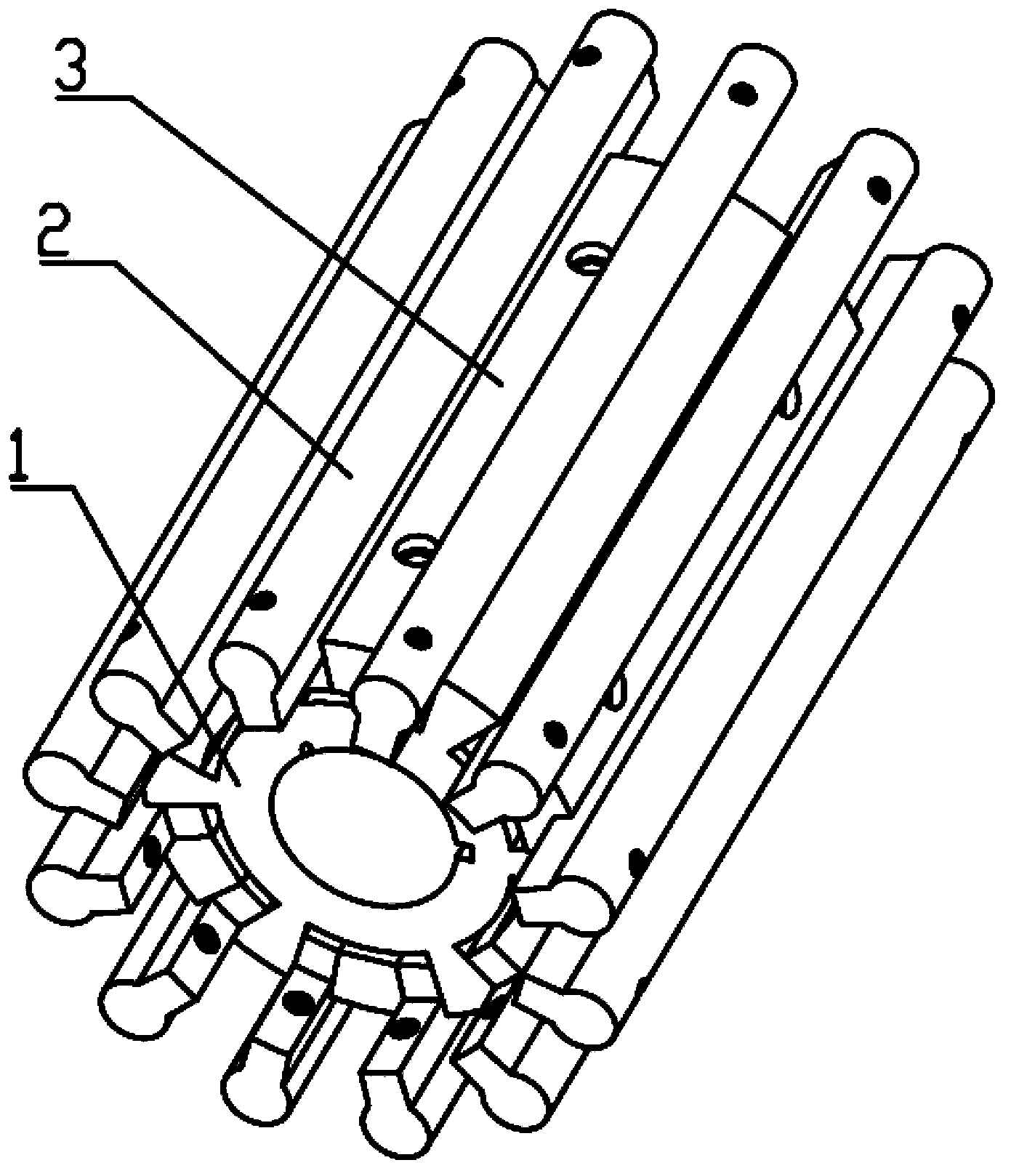

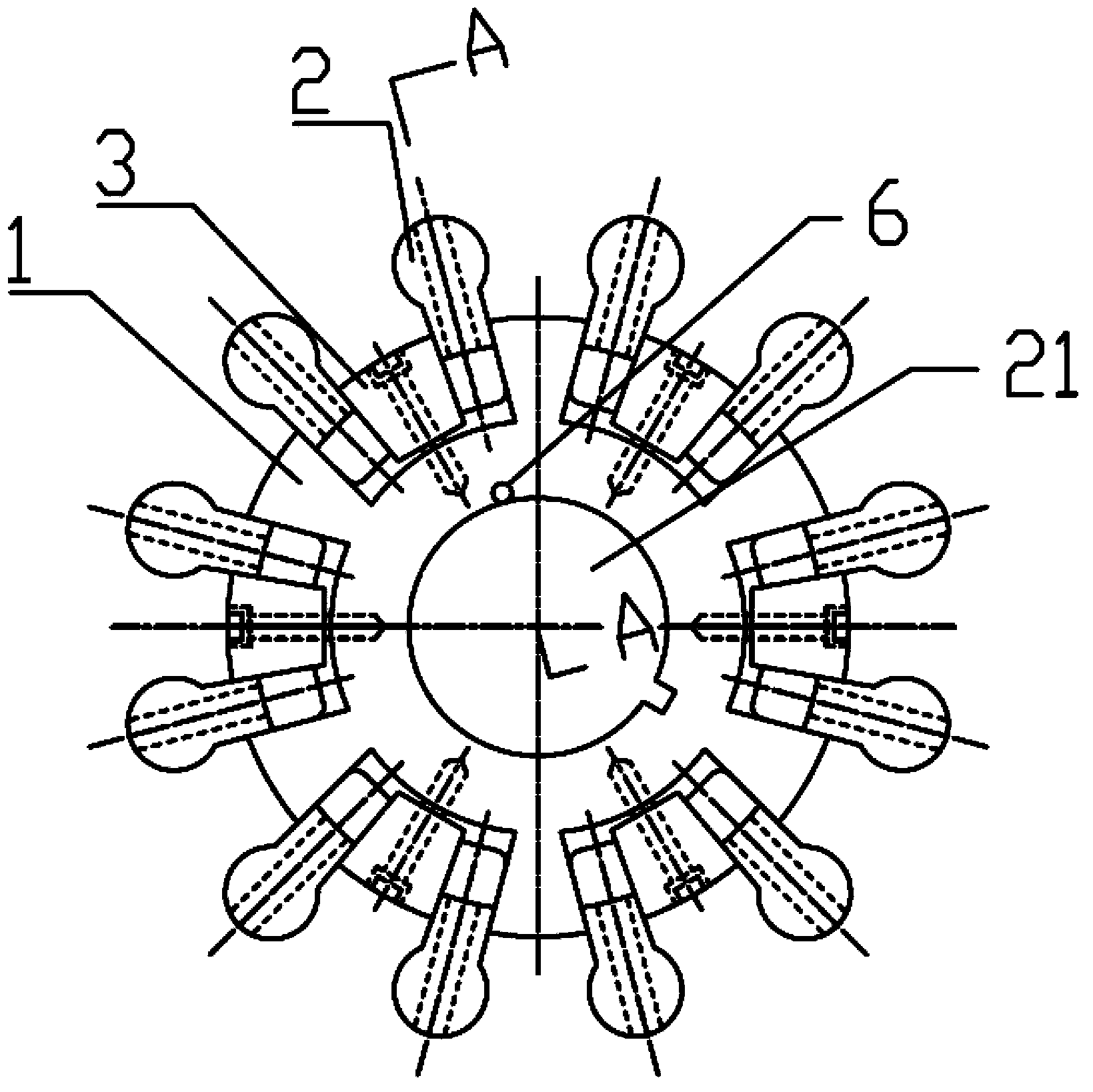

[0020] The forming roll pair of the present invention is composed of an upper forming roll 11 and a lower forming roll 12. The upper and lower forming rolls are composed of a shaft roll frame 1, a roller column 2 and a briquetting block 3. A pair of upper forming rolls and a lower forming roll, Parallelly arranged on the frame 13 through bearings, the central axis of the forming roller pair is connected with the output of the power system, see figure 1 , figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com