Additive blend for enhancing water vapor permeability and increasing cell size in thermoplastic foams

一种热塑性聚合物、渗透度的技术,应用在运输和包装、薄料处理等方向,能够解决泡孔尺寸小不能发泡的产品绝缘值、高密度、高成本等问题,达到改善蒸气渗透性、低全球变暖能力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

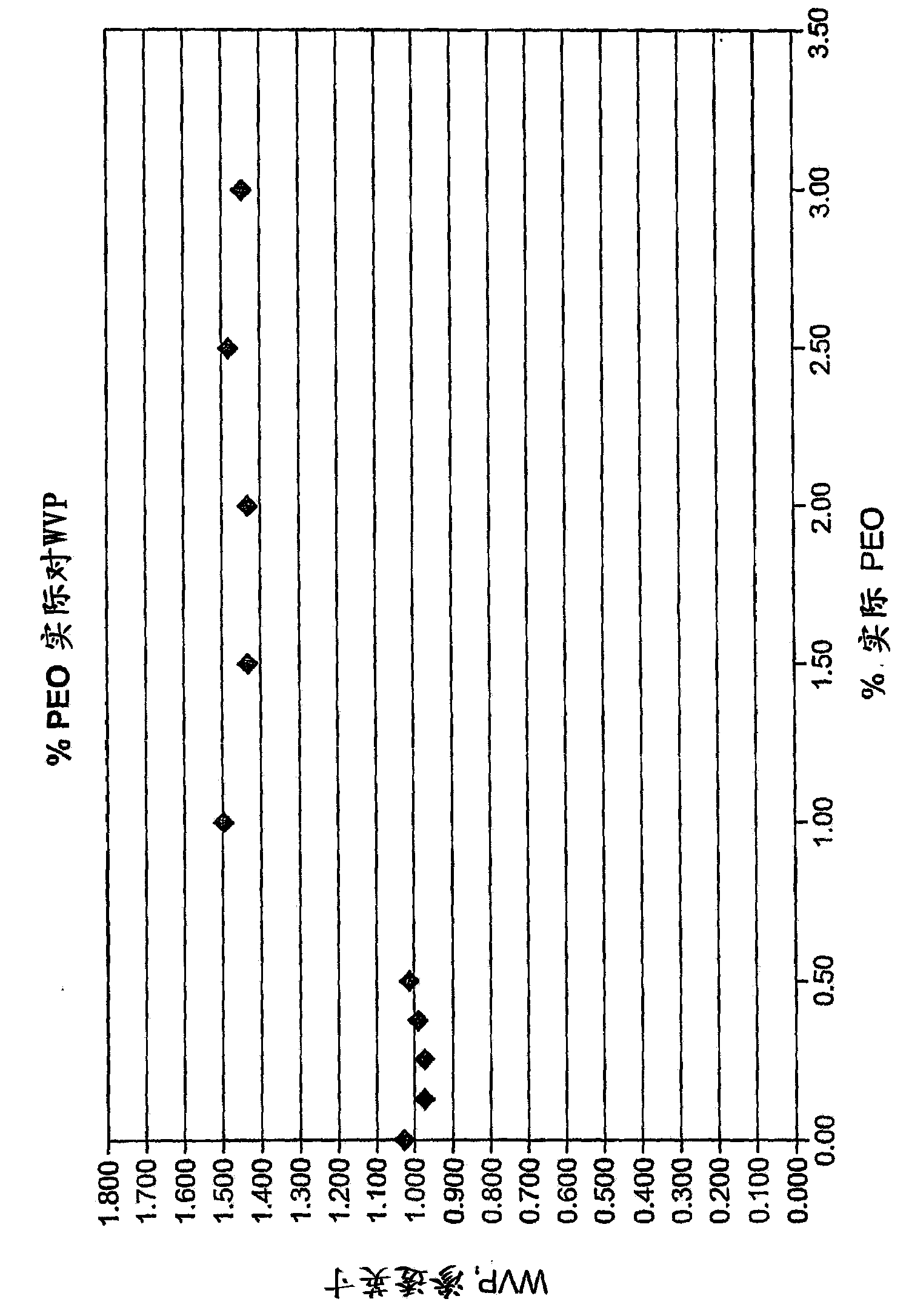

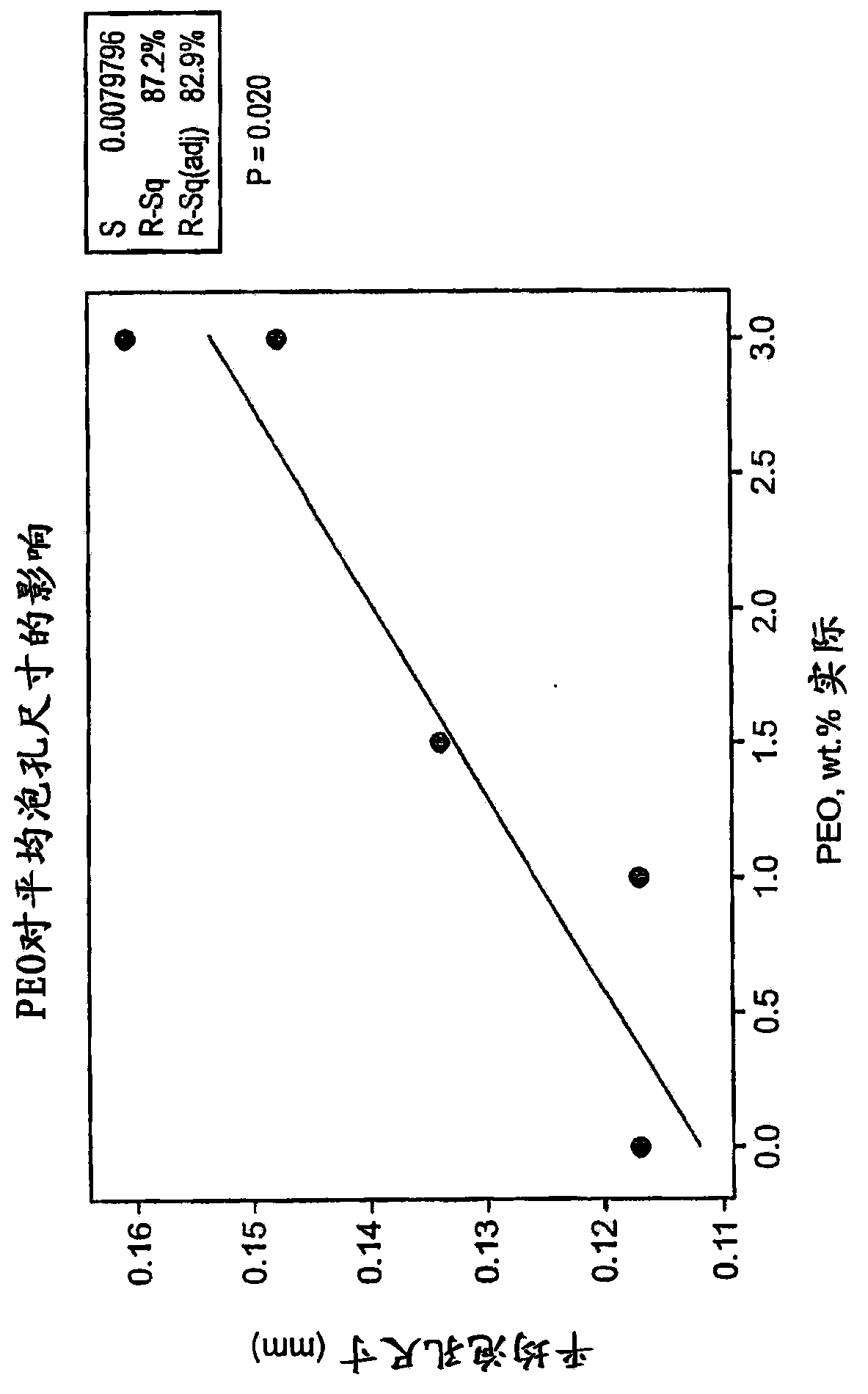

[0087] water vapor permeability

[0088] Blends described in Table 1 were formed containing polystyrene, HFC-134a / HFC-152a as a blowing agent, graphite, and a blend of ethoxylated polyethylene oxide and styrene / maleic anhydride copolymer composition (additive blend) and used to generate foam board samples. Specifically, nano-graphite was compounded into general-purpose polystyrene with the following properties at an active amount of 20%: Mw 253000, Mn 613000, Mz 532500, Mw / Mn (polydispersity) 3.44. The additive blend was compounded into general purpose polystyrene at 0.5%, 1 / 0%, 1.5%, 2.0%, 4%, 6%, 8%, 10%, and 12% active. The blowing agent used was a 50:50 blend of HFC-134a / HFC-152a in an amount of 7.5 wt%, based on resin weight. Foam boards were formed from this composition on an Owens Corning horizontal pilot line extruder at a dry process rate of 160 kg / hour.

[0089] Table 1

[0090]

[0091] Once the foam panels were prepared, the panels were tested for water vapo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com