Working electrolyte for aluminium electrolytic capacitor and preparation method

An aluminum electrolytic capacitor and electrolyte technology, applied in the field of electrolyte, can solve the problems such as performance deterioration and product failure of aluminum electrolytic capacitors, and achieve the effects of low cost, high spark voltage and high oxidation efficiency

Active Publication Date: 2012-11-14

GUANGXI JIGUANG ELECTRONICS TECH CO LTD

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

This technology has several benefits that make it more affordable than previous methods while also being able to withstand very harsh environments at temperatures above 90°C for longer periods without losing its effectiveness or causing damage during use.

Problems solved by technology

This patents discusses different types of technical problem addressed by this patented research group on electrical components like aluminized metal plasma capacitors (AML). These devices require good insulation properties at very high voltages while being able to maintain stable operating temperatures over many years without losing effectiveness caused by humidity. Additionally, these materials should have excellent resistance against corrosion when exposed to highly acid environments containing sulfurous compounds.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

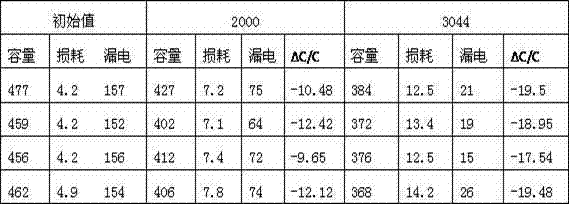

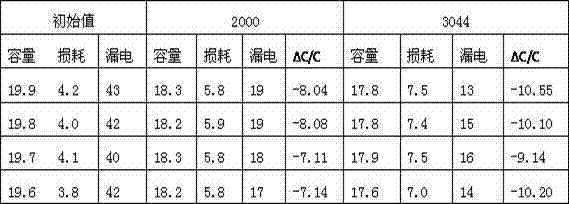

[0024] Example 1: Aluminum electrolytic capacitor 22UF400V, 16*20, the test temperature is 105°C, the test voltage is 400V, the test conditions are indoor temperature 25°C, humidity 65%, 120HZ.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of electrolyte, in particular to working electrolyte for an aluminium electrolytic capacitor and a preparation method. The electrolyte comprises 75 percent to 85 percent of ethylene glycol, 1 percent to 5 percent of pure water, 2 percent to 8 percent of adipic acid, 2 percent to 8 percent of ammonium adipate, 0.1 percent to 2 percent of ammonium hypophosphite, 0.1 percent to 2 percent of meta-nitro acetophenone and 5 to 10 percent of polyethylene glycol (PEG). The working electrolyte has the beneficial effects that the working electrolyte has low cost, high oxidation efficiency, high electric conductivity and high spark voltage, can stably work for a long time under the high temperature condition, has service life of 3,000h at a temperature of 105 DEG C and can be widely applied to the fields of a switching power supply, a power adapter and the like.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Owner GUANGXI JIGUANG ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com