Sequential accelerated degradation test optimal design method based on relative entropy

An accelerated degradation test and optimized design technology, applied in calculation, special data processing applications, instruments, etc., to achieve the effect of reducing test design errors, saving test time and sample size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

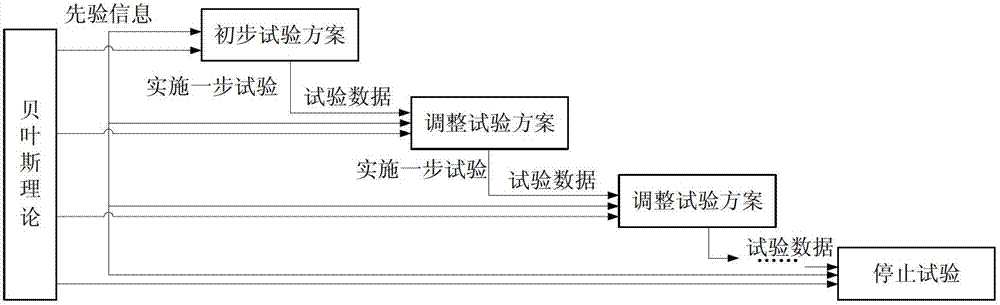

Method used

Image

Examples

Embodiment

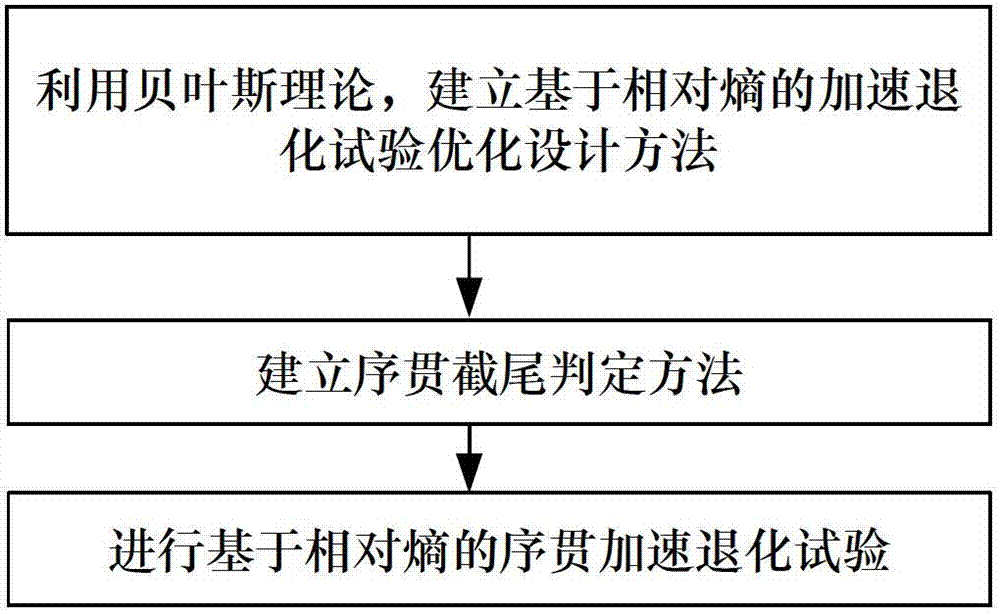

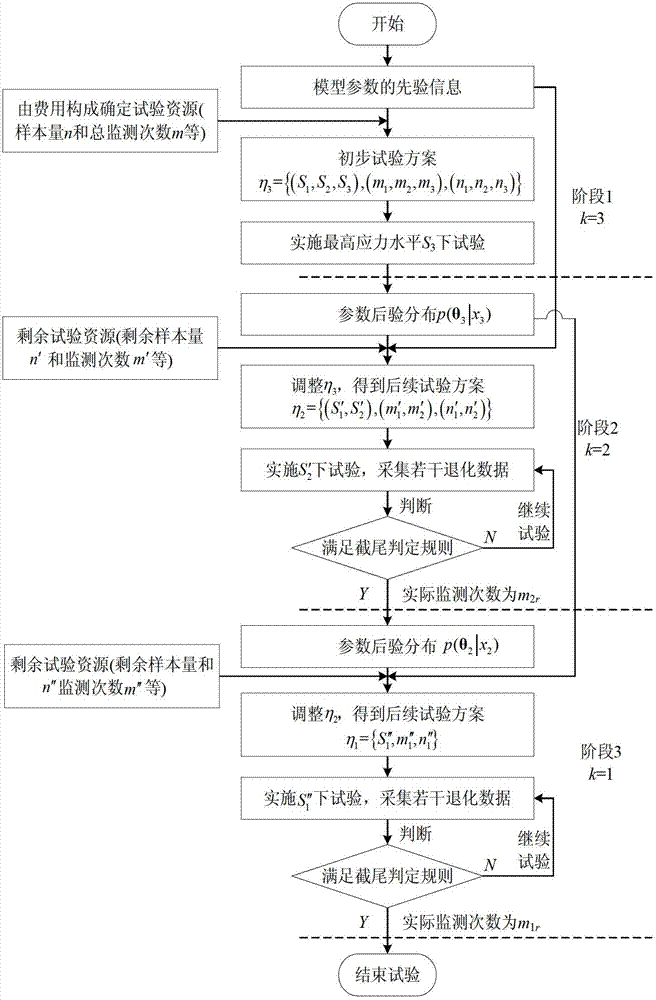

[0154] For a superluminescent diode (SLD), the step stress sequential accelerated degradation test optimization design is implemented based on the relative entropy, and the steps are as follows:

[0155] Step 1. Using Bayesian theory to establish an optimal design method for accelerated degradation experiments based on relative entropy.

[0156] Step 1 is the basis of Step 2 and Step 3 of the present invention. The specific implementation of Step 1 will be described below by taking the optimization of the initial test scheme according to the method of Step 1 in Step 3 as an example.

[0157] (1) Determine the product performance degradation model and acceleration model, and then give the prior distribution of model parameters based on historical data. Based on the design information, historical data, and similar product information of the tested product SLD, the model and assumptions are given as follows,

[0158] 1. Assumption:

[0159] A1: The degradation trend is monotono...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com