Nut buckle

A nut and pin technology, applied in the field of nut buckles, can solve the problems of surface scratches and wear of trapezoidal pins, affecting service life and installation stability, etc., so as to avoid hard extrusion and scratches, ensure installation convenience, and avoid hard scratch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

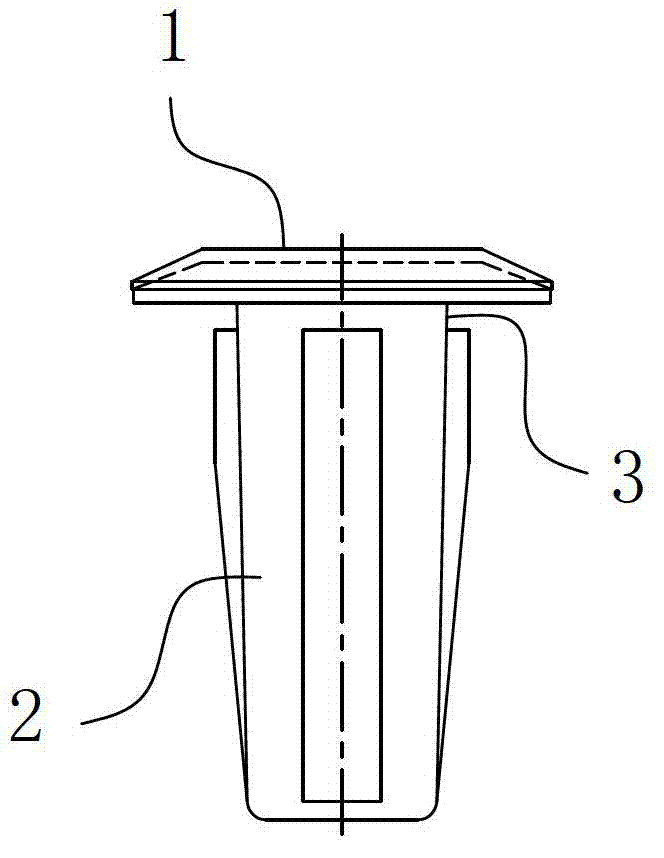

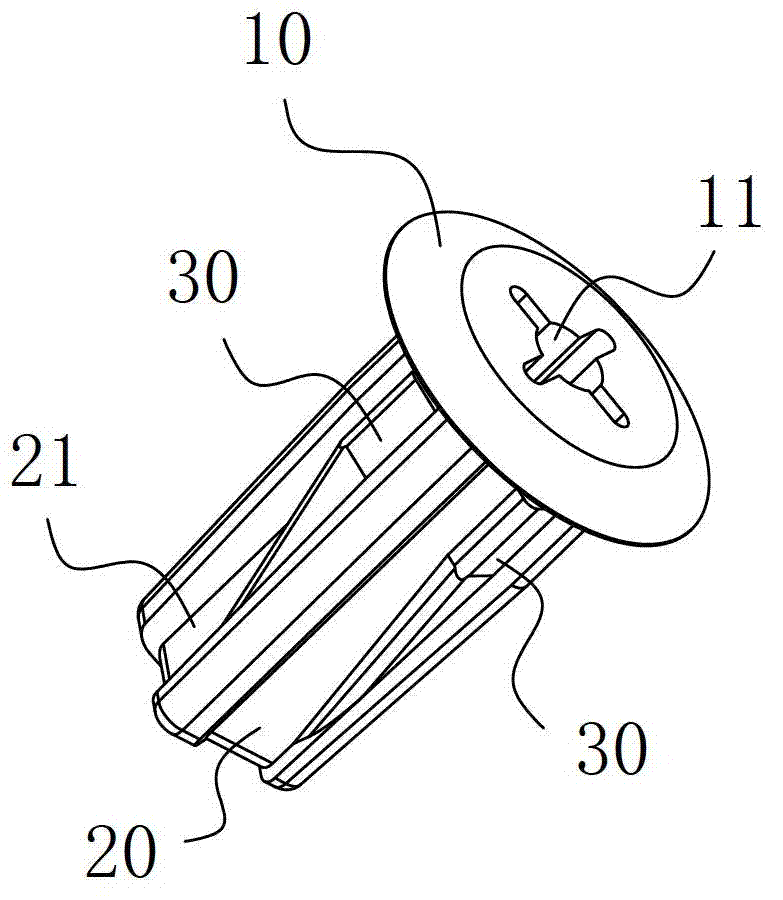

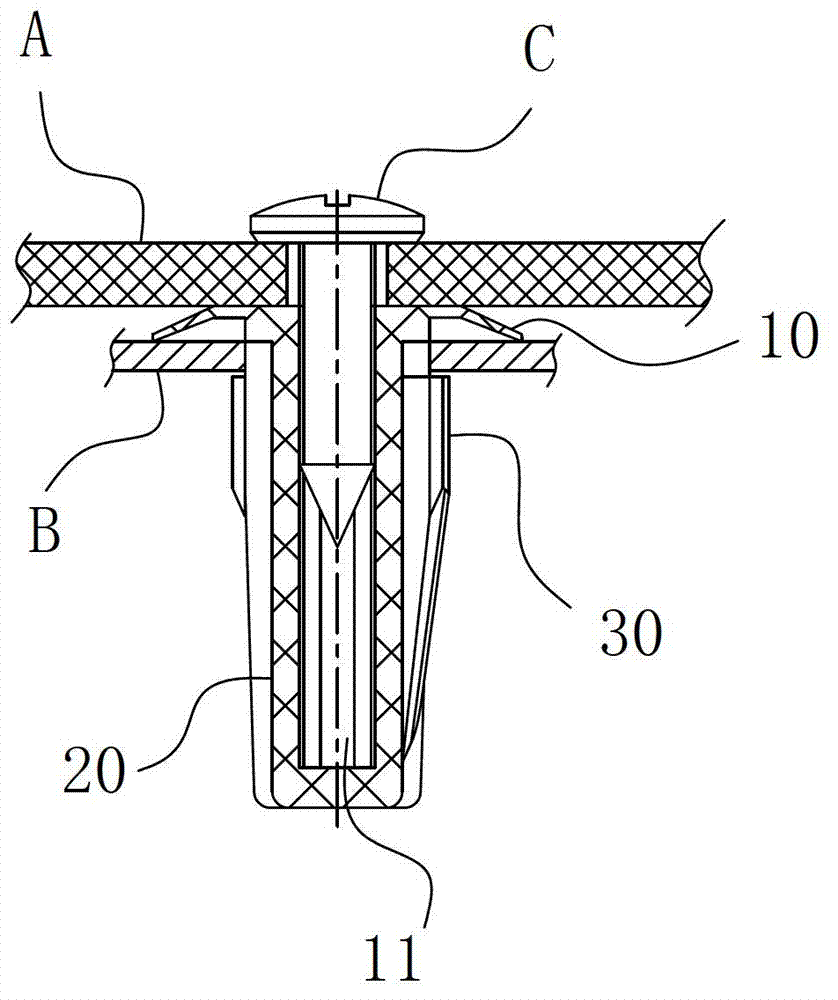

[0012] A nut buckle, comprising a cap 10 and a pin portion 20 formed by extending vertically outward from one side of the cap 10, the pin portion 20 is in a tapered shape with a thin tip and a thick root, and the pin portion 20 is arranged along its circumference There is an elastic flap 30, and there is an elastic movable gap between the elastic flap 30 and the outer wall of the latch portion 20. One side of the elastic flap 30 is fixed on the latch portion 20, and the length direction of the joint line of the two extends along the length direction of the latch portion 20. It is provided that a gap for accommodating sheet metal is reserved between the side of the elastic flap 30 where the root of the latch portion 20 is located and the end surface of the side of the cap 10 .

[0013] Its specific structure is as Figure 1-6 As shown, the present invention changes the traditional hard constriction design into the elastic bayonet structure of the present invention; when in use,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com