Concrete pouring method for combined structural steel and concrete structure of high-rise building

A technology for high-rise buildings and composite structures, applied in building construction, building material processing, construction, etc., can solve problems such as air is not easy to discharge concrete, achieve reasonable and convenient construction technology, ensure compactness, and improve construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] The concrete pouring method that a kind of high-rise building steel-concrete composite structure of the present embodiment is used comprises the following steps:

[0052] (1) Install shaped steel columns, shaped steel beams, steel bars and templates;

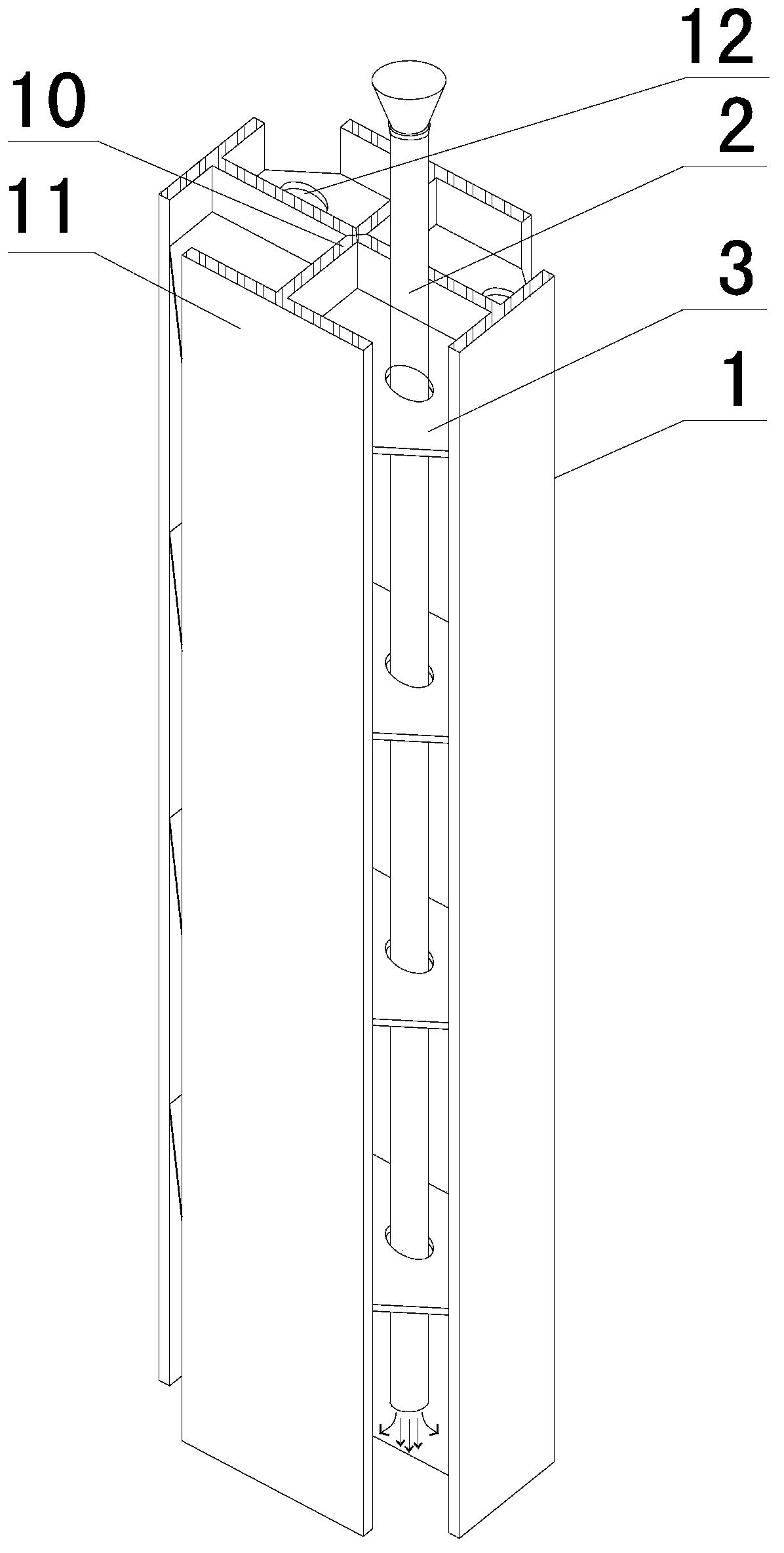

[0053] (2) if figure 1 As shown, the concrete pouring string tube 2 is installed in the steel column 1;

[0054] (3) Inject cement mortar with a thickness of 50~100mm at the bottom of the steel column;

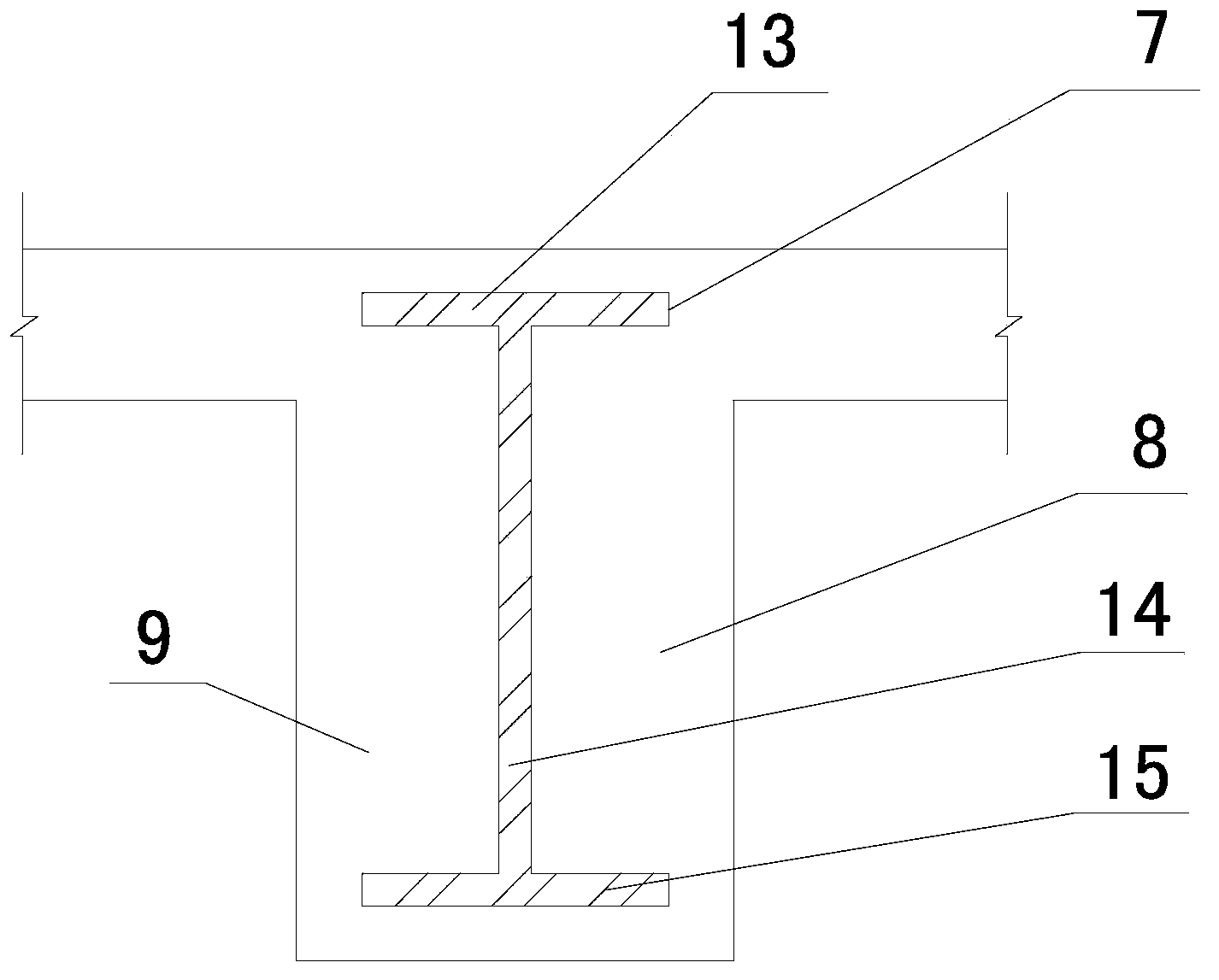

[0055] (4) According to the cross-section division of the steel column, adopt the method of shifting the pouring progress at the same time, pour concrete into the steel column through the concrete pouring string 2 according to the order of each grid, and vibrate the concrete through the vibrating rod 4 at the same time, Until the height of the concrete in the shaped steel column is 10~20mm higher than the bottom surface of the shaped steel beam; specifically:

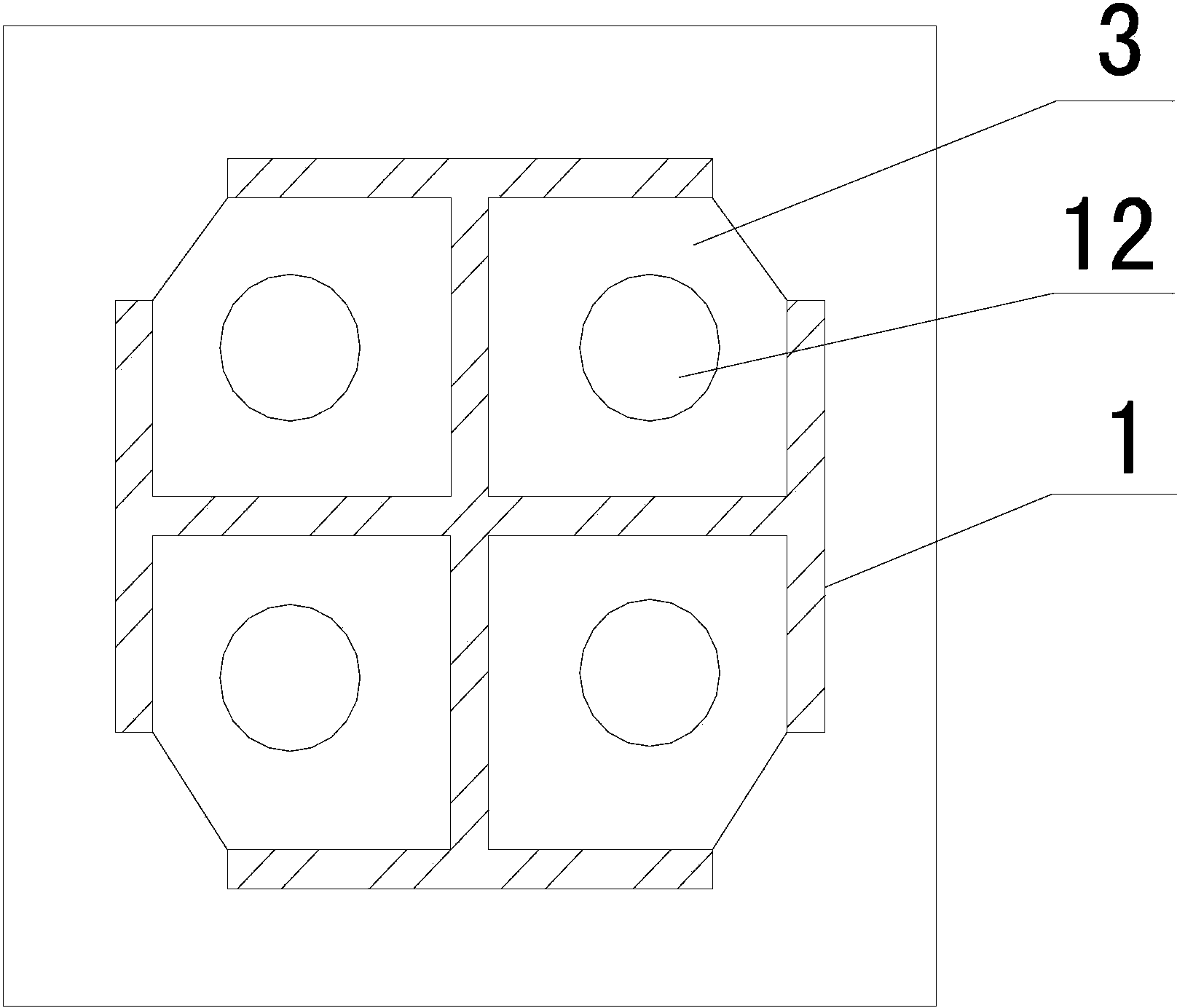

[0056] (4-1) If figure 2 As shown, according to the cros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com