Ceramic slurry for combining with micro powder

A technology of ceramics and slurry, applied in the field of ceramic slurry, can solve the problems affecting the performance and overall appearance of ceramic tiles, poor bonding, etc., and achieve the effect of low cost, good compatibility and good gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] For better illustrating the present invention, facilitate understanding technical scheme of the present invention, typical but non-limiting embodiment of the present invention is as follows:

[0039] The composition of the wood pulp described in Examples 1-3 and Comparative Examples 1-2 is as described in Table 1 in parts by weight.

[0040] Table 1 embodiment 1-3 and comparative example 1-2 described pulp composition by weight

[0041]

[0042] ——Indicates that the corresponding substance is not contained.

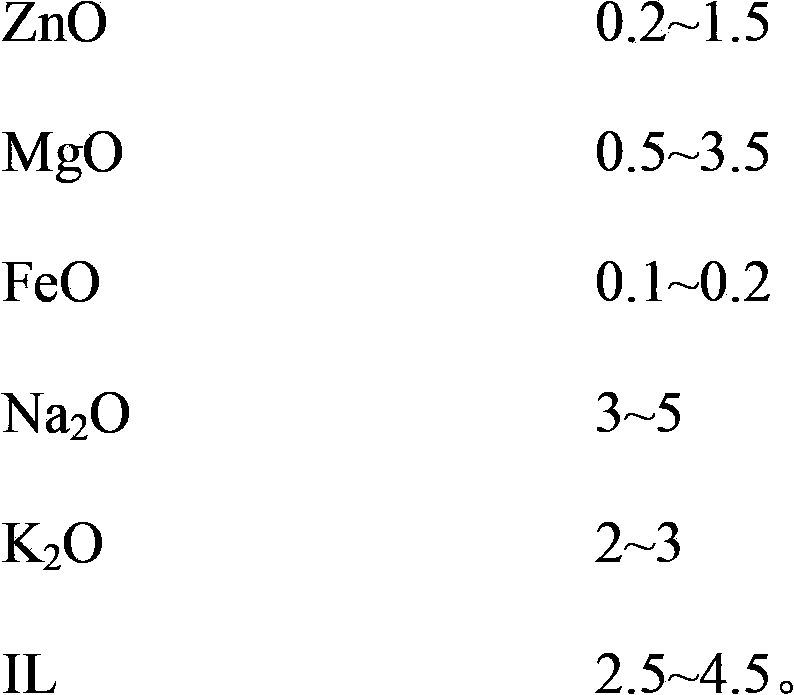

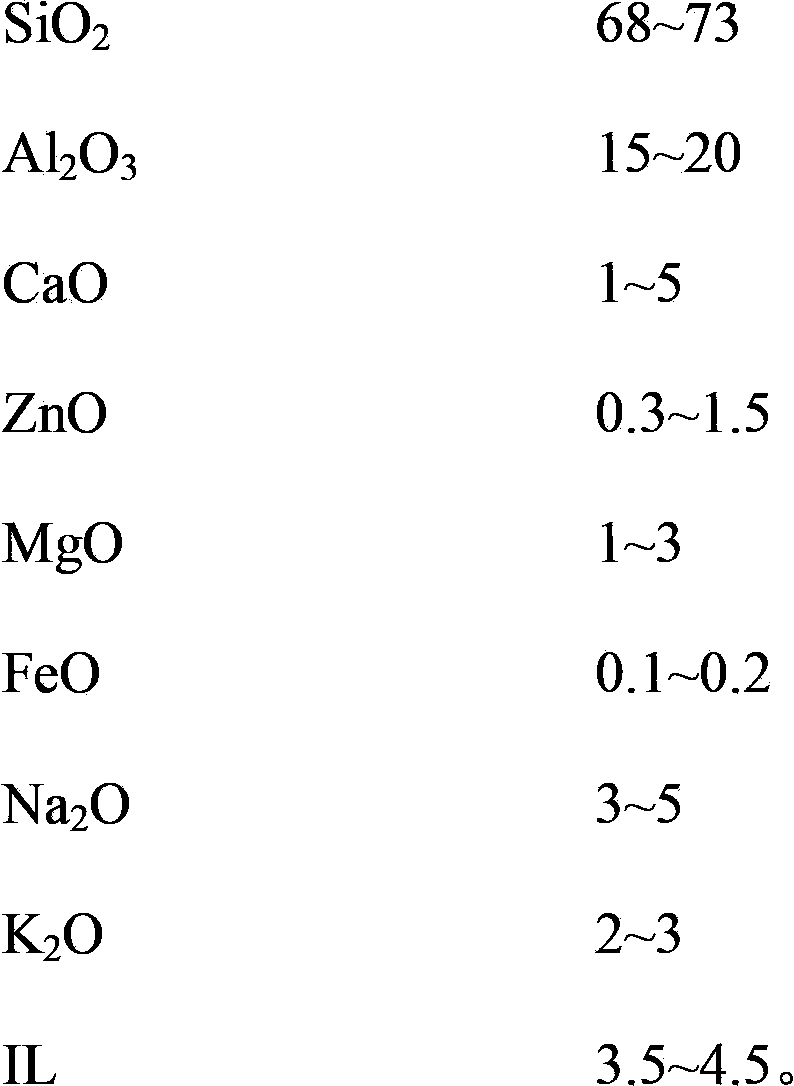

[0043] Existing micropowder comprises by weight: SiO 2 : 68~70, Al 2 o 3 : 17~21, CaO: 0.4~0.7, MgO: 0.3~0.5, FeO: 0.1~0.2, Na 2 O and K 2 O: 3.5~5, IL: 3.5~4.5.

[0044] The phenomenon that the volume or length of an object increases with the increase of temperature is called thermal expansion. The thermal expansion of ceramic materials is expressed by linear expansion coefficient and volume expansion coefficient. The linear expansion coefficient refers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com