Accessory position manipulating and automatic collision prevention monitoring method orientating to dual-arm engineering machinery

A technology of construction machinery and double arms, which is applied in the direction of manipulators, manufacturing tools, etc., to achieve the effect of improving operation efficiency, improving efficiency and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

[0049] The control method and the self-collision avoidance method of the present invention are described for a construction machine with a classic double six-joint working arm.

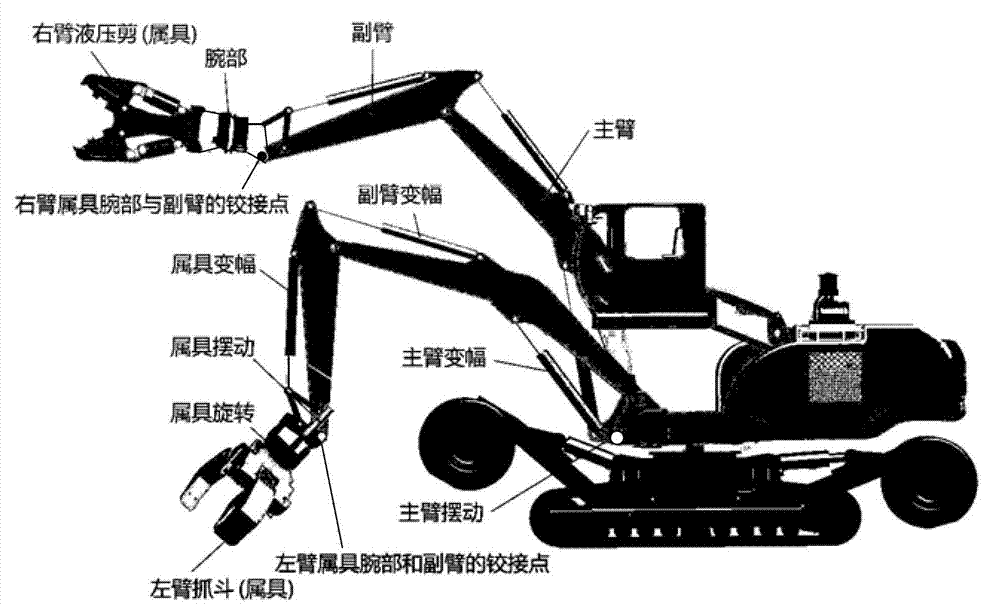

[0050] Such as figure 1 As shown, it is a 3D simulation model diagram of construction machinery with dual six-joint working arms. Among them, the single working arm is composed of main (articulated) arm, auxiliary (articulated) arm, attachment wrist and end attachment, including 6 joints in total, and the 6 joints from the front cab to the end attachment are as follows: main The left and right swing joints of the arm, the up and down luffing joints of the main arm, the up and down luffing joints of the auxiliary arm, the up and down luffing joints of the attachment, the left and right swinging joints of the attachment, and the rotation joints of the attachment respectively realize the left an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com