High-precision inner spherical surface machining tool

A technology for processing machine tools and inner spherical surfaces, which is applied in the direction of metal processing machinery parts, metal processing equipment, milling machine equipment, etc., can solve the problem of unreasonable design of longitudinal feed control accuracy, and the roundness and roughness of inner spherical surfaces cannot meet the quality requirements, etc. problems, to achieve the effect of reasonable overall structure design, good reliability and convenient operation

Active Publication Date: 2012-11-14

上海紫邦科技有限公司

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the design of the control accuracy of longitudinal feed and lateral feed is unreasonable, and the roundness and roughness of the processed inner spherical surface cannot meet the quality requirements for matching with the outer spherical surface

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

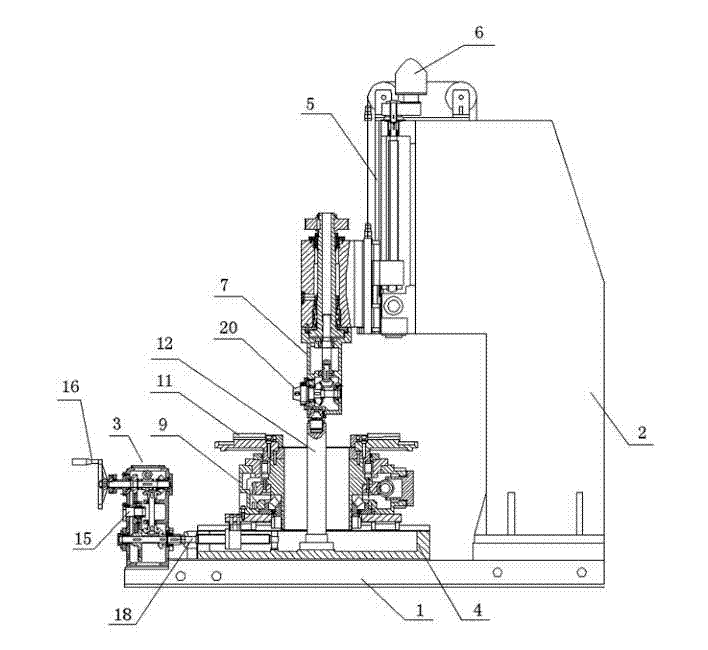

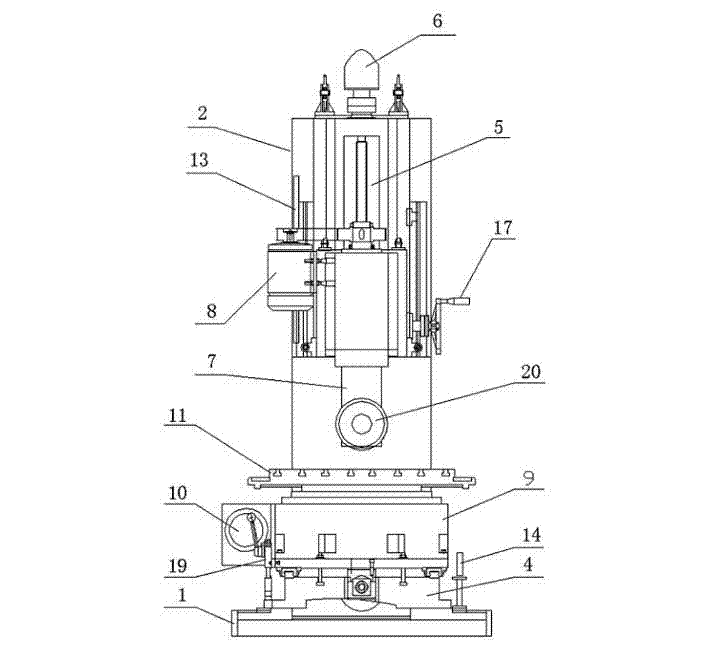

The invention discloses a high-precision inner spherical surface machining tool, which includes a machine base, a milling cutter base, a horizontal feeding power case, a horizontal feeding slide table, a perpendicular feeding slide table and a machine tool control system. On the perpendicular feeding slide table is mounted a cutter power case driven by a perpendicular servo motor to slide perpendicularly, the lower end of the cutter power case is provided with a milling cutter seat driven by a cutter servo motor via a transmission rod and a bevel gear to rotate, and on the milling cutter seat is mounted a tool bit. On the horizontal feeding slide table is mounted a horizontal rotary power case driven by the horizontal feeding power case via a lead screw to slide horizontally, and on the horizontal rotary power case is mounted a work table driven by a work table servo motor to rotate. The inner spherical surface machined by the inventive tool has high precision, the working efficiency is high, the operation is convenient and the performance is stable and reliable.

Description

technical field [0001] The invention belongs to industrial processing machinery, in particular to a high-precision inner spherical surface processing machine tool. Background technique [0002] In the prior art, when machining an inner spherical surface on an ordinary lathe, the workpiece to be processed is generally clamped on the lathe chuck, the turning tool mounted on the tool holder is shaken into the inner hole of the workpiece, and the workpiece is driven to rotate by the chuck. Manual or electric control of longitudinal feed and lateral feed to complete the processing of the inner spherical surface. However, the design of the control precision of longitudinal feed and lateral feed is unreasonable, and the roundness and roughness of the processed inner spherical surface cannot meet the quality requirements for matching with the outer spherical surface. Contents of the invention In order to overcome the shortcomings of the prior art, the present invention provide...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23C3/00B23Q5/40B23Q5/36B23Q17/24

Inventor 不公告发明人

Owner 上海紫邦科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com