Lubricating greases containing lignosulfonate, the production thereof, and the use thereof

A technology of lignosulfonate and calcium lignosulfonate, which can be used in lubricating compositions, petroleum industry, additives, etc., and can solve the problems of huge cost factors and consumption of synthetic chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

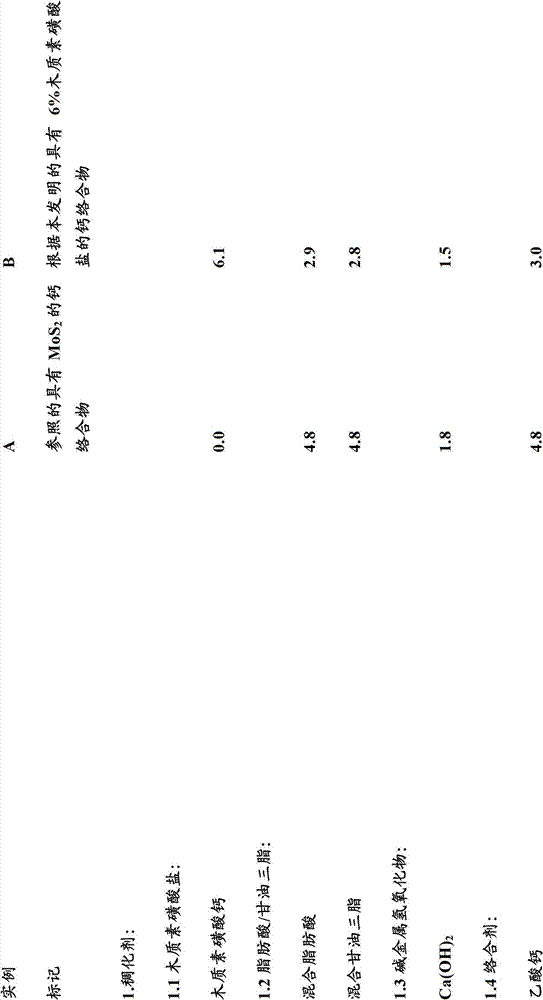

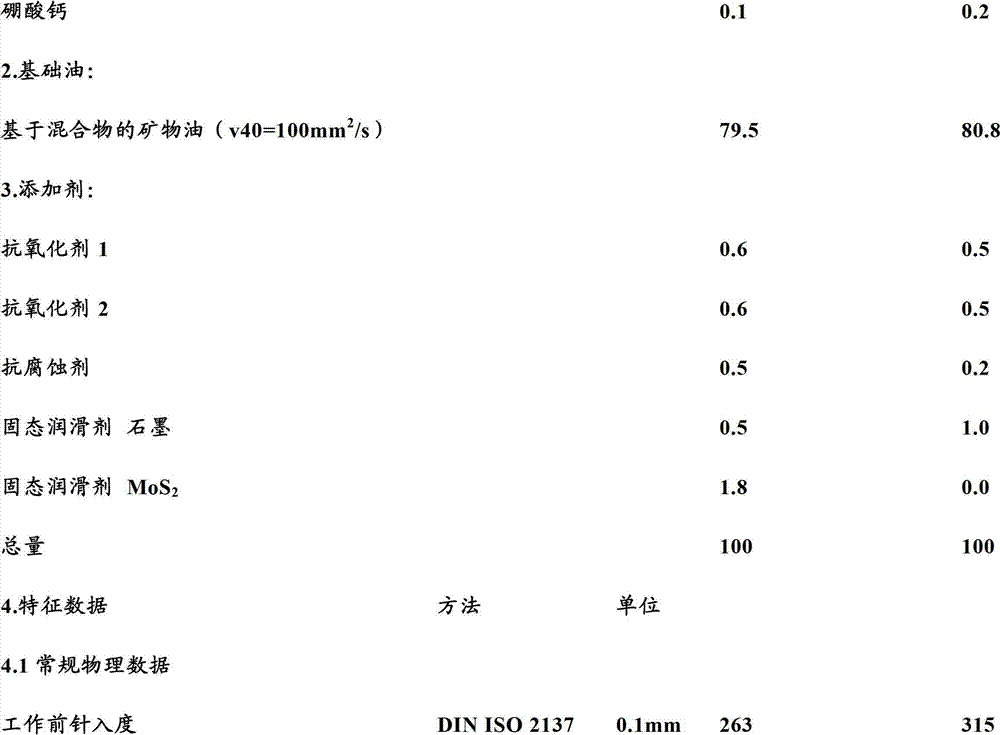

example A( comparative example )

[0076] In the reactor, 958 g tallow fatty acid, 958 g tallow, 985 g calcium acetate, 27.7 g trisodium phosphate, 27.7 g calcium borate and 358 g calcium hydroxide were placed in 12000 g base oil mixture and 150 ml water was added. With stirring, the batch was heated to 198° C. with a defined temperature program, and the added water and the water of reaction evaporated there. In the cooling phase, additives are added to the batch at specific temperatures (see table). After adjusting the furnish to the desired consistency by adding 3700 g of the base oil mixture, the final product was homogenized by means of a toothed colloid mill. The grease thus obtained is suitable, for example, as constant velocity joint shaft grease.

example B

[0078] In the reactor, put 460g tallow fatty acid, 445g tallow, 460g calcium acetate, 27.7g trisodium phosphate, 27.7g calcium borate, 168g calcium hydroxide and 920g calcium lignosulfonate (manufactured by Borregard Lignotech) in 14000g base oil mixture Norlig 11D powder), and add 150ml of water. With stirring, the batch was heated to 208° C. with a defined temperature program, and the added water and the water of reaction evaporated there. During the cooling phase, at specific temperatures, additives are added to the batch (see table). After adjusting the furnish to the desired consistency by adding 3450 g of the base oil mixture, the final product was homogenized by means of a toothed colloid mill. The grease thus obtained is suitable, for example, as constant velocity joint shaft grease.

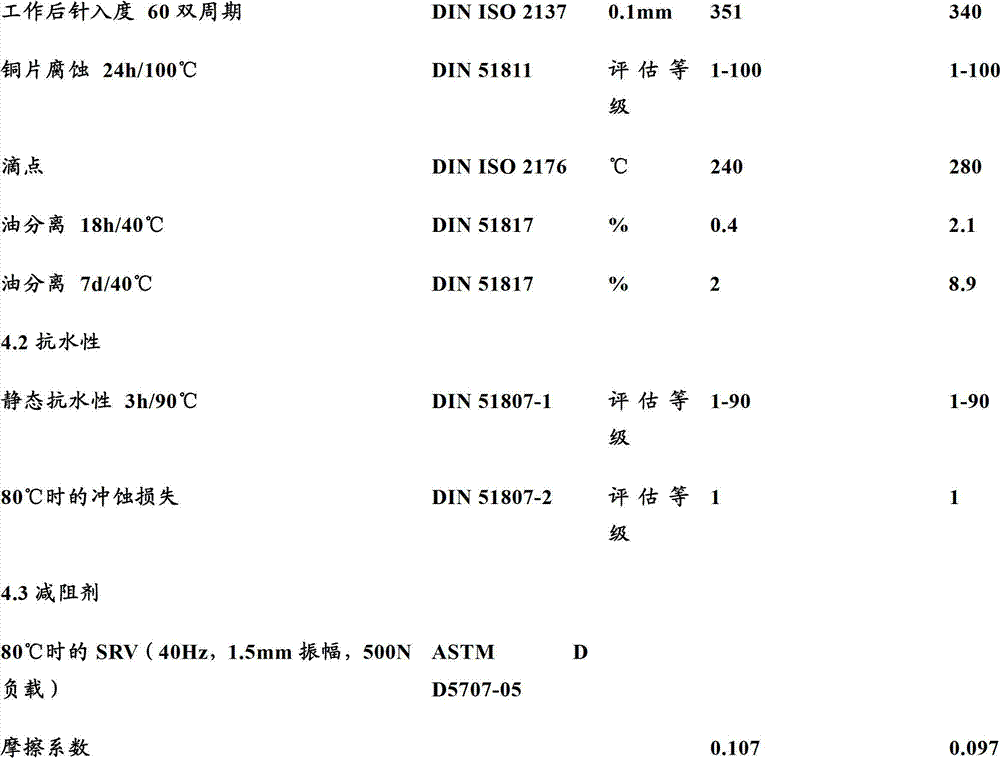

example C( comparative example )

[0080] In the reactor, 800 g of 12-hydroxystearic acid, 288 g of sebacic acid, 388 g of calcium acetate and 157.3 g of calcium hydroxide were placed in 5000 g of the base oil mixture. 64g of LiOH×H 2 O was dissolved in 250ml water and added. With stirring, the batch was heated to 200° C. with a defined temperature program, and the added water and the water of reaction evaporated there. In the cooling phase, at a specific temperature, additives are added to the batch.

[0081] After adjusting the furnish to the desired consistency by adding 3116 g of the base oil mixture, the final product was homogenized by means of a toothed colloid mill. The grease thus obtained is suitable, for example, as rolling bearing grease.

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com