Intelligent air-water spraying control dust falling device for blasting of coal mine

A technology of intelligent control and dust suppression device, applied in safety devices, dust prevention, mining equipment, etc., can solve the problems of inability to use power outage, affect the use effect, and water pressure is difficult to achieve the dust suppression effect, etc., to reduce the dust concentration and increase the dust suppression effect. , The effect of preventing gas accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

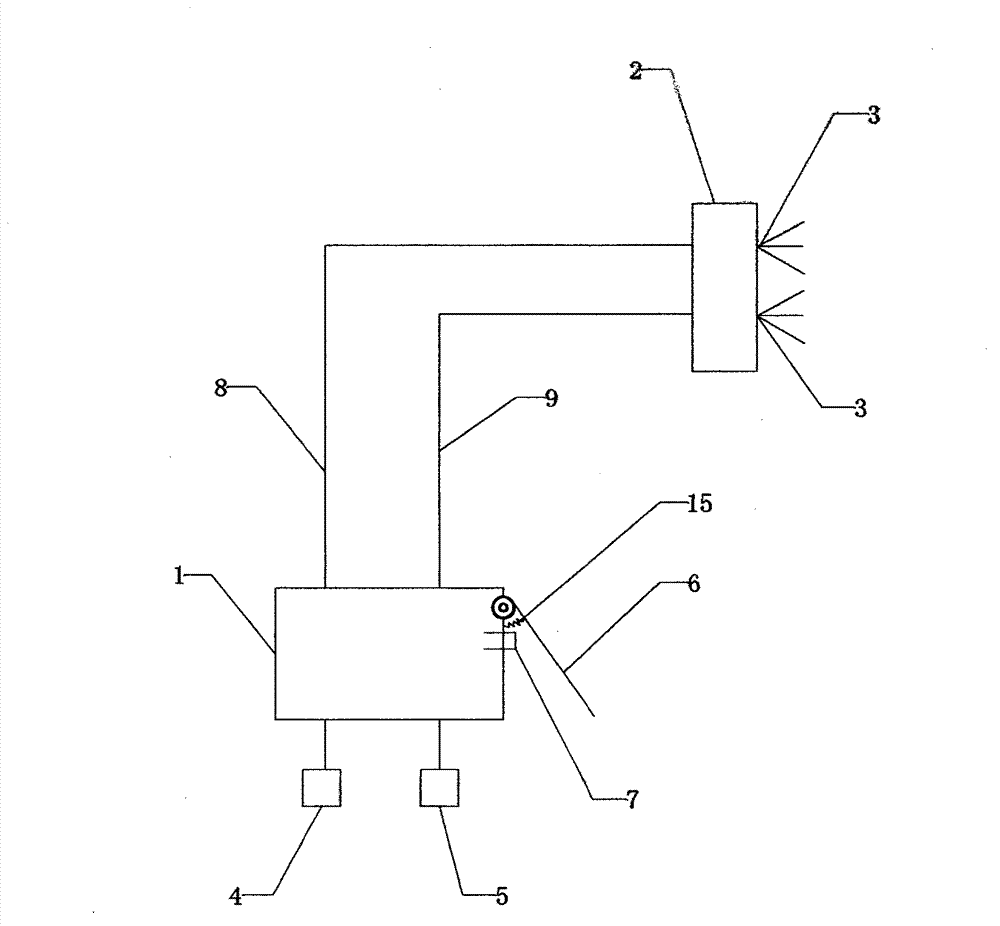

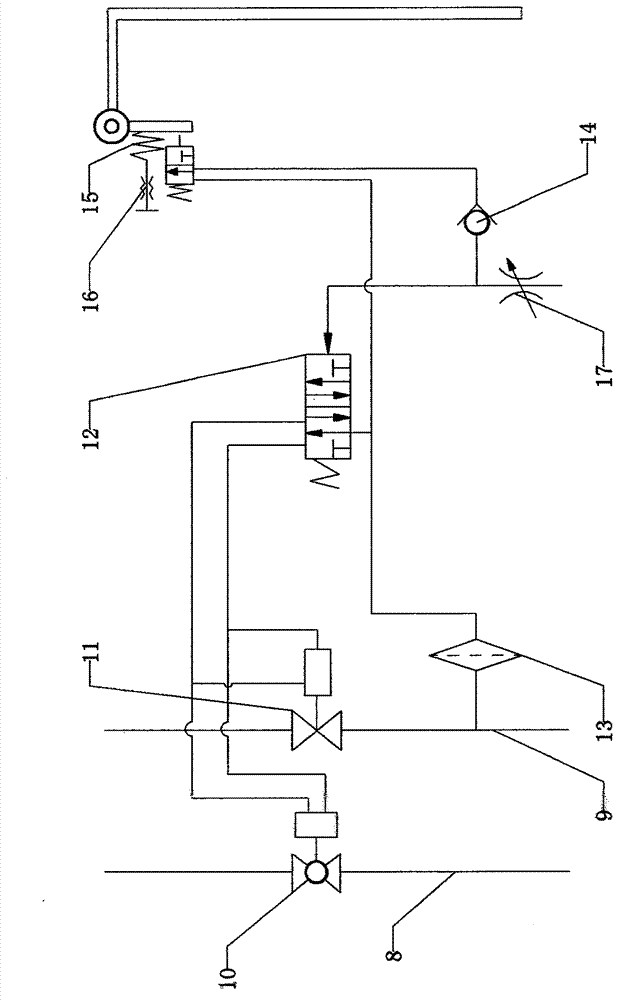

[0014] Such as Figure 1-2 As shown, a coal mine blasting intelligent control gas-water spray dust suppression device includes a valve group control system 1, a spray gas-water mixing chamber 2 and a nozzle 3, and the bottom of the valve group control system 1 is connected to a pressure water source 4 and a A pressure wind source 5, a shock wave receiving plate 6 is provided on the right end surface of the valve group control system 1 near the top, and a mechanically controlled pneumatic valve 7 connected to the valve group control system 1 is provided below the shock wave receiving plate 6. The valve group control system 1 The top of the spraying air-water mixing chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com