Sliding frame structure in construction of large-area multi-column-point supported reticulated shells

A large-area, construction-in-progress technology, applied in building construction, building material processing, construction, etc., can solve problems such as unreasonable economy and time, and achieve the effects of material stacking and evacuation, convenient feeding, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

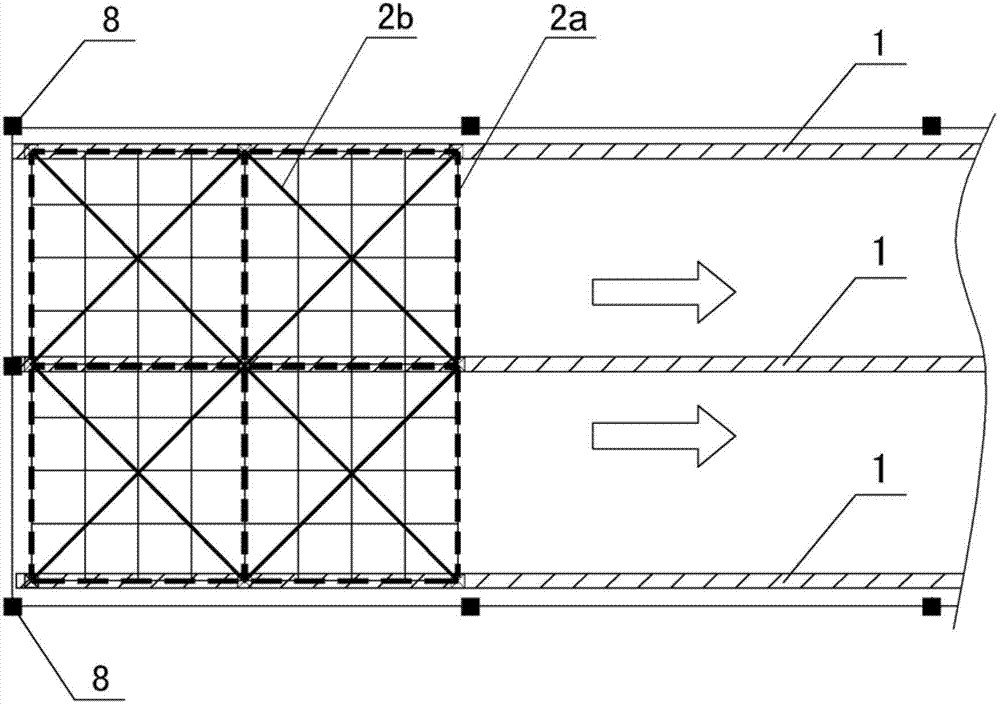

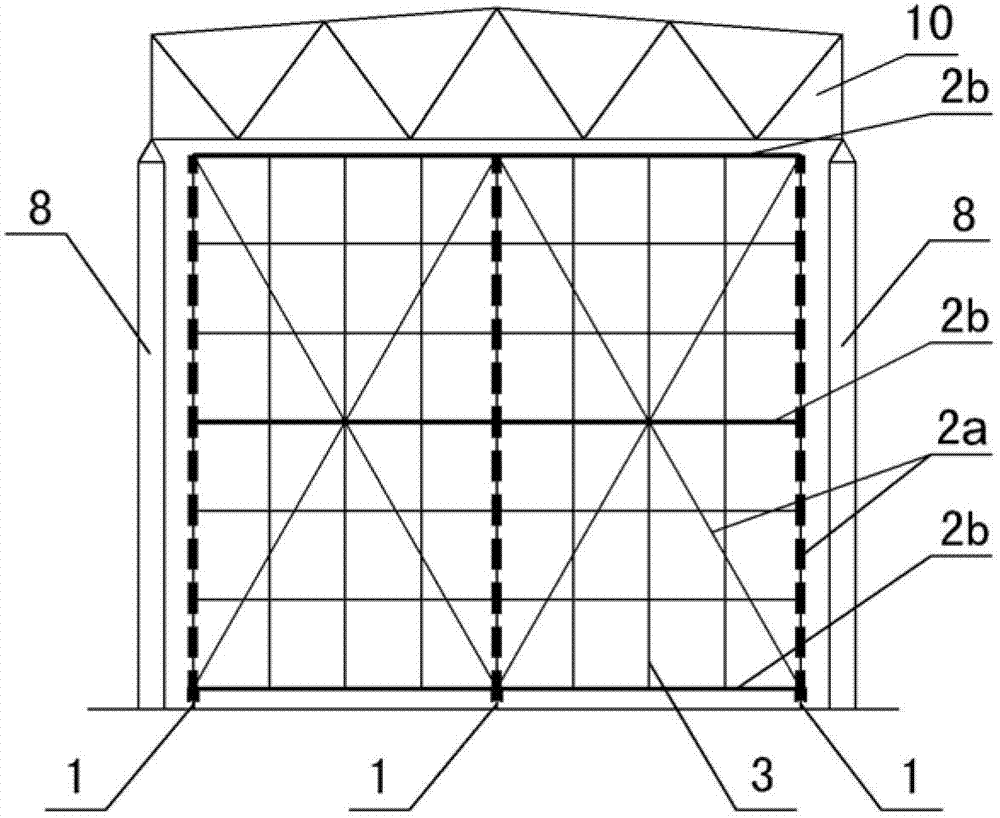

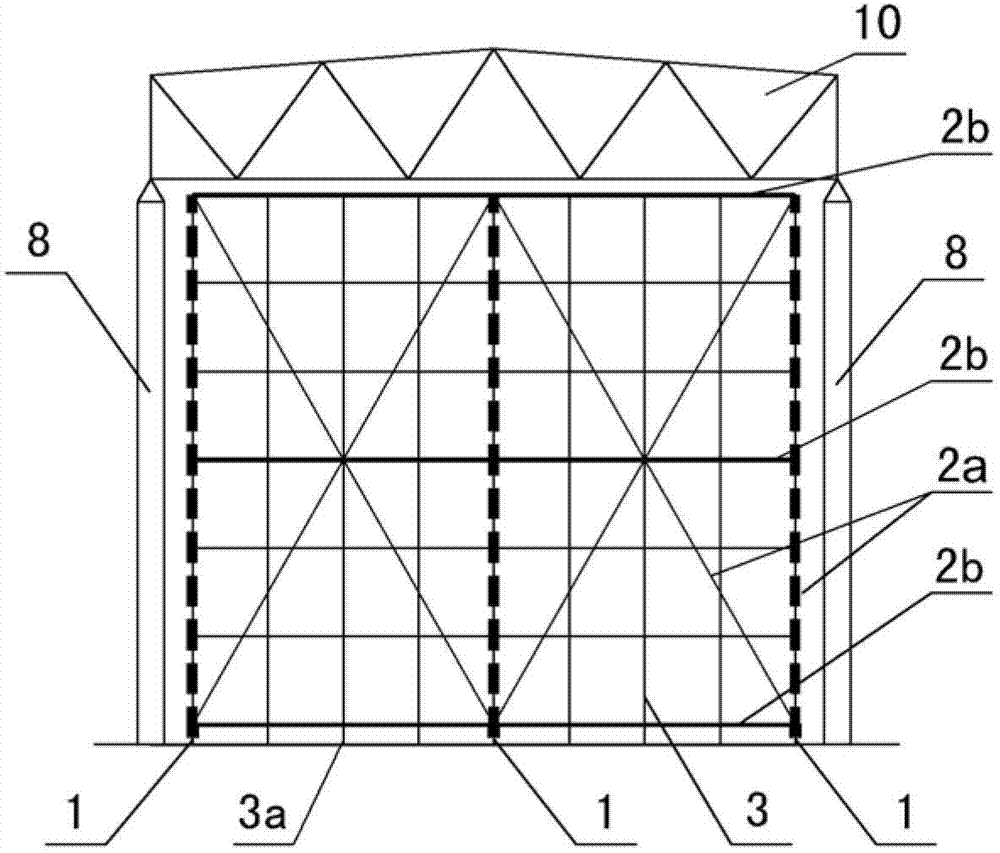

[0024] see figure 1 and figure 2 The characteristics of the carriage structure in the large-area multi-column point support reticulated shell construction in this embodiment are: on the ground where the plane projection of the roof reticulated shell 10 is located, each slide rail 1 is arranged in parallel, for each structural column 8, with The span between two adjacent vertical structural columns is one span, and the distance between two adjacent horizontal structural columns is a column spacing. The inter-span unit steel pipe scaffolding is independently installed within the range of one column spacing between each span, and the inter-span unit steel pipe scaffolding The rolling support is on the slide rails 1 arranged in parallel, and can move along the slide rails, and an operating platform is set up on the top of the steel pipe scaffolding 1 between the spans.

[0025] see figure 2 and image 3 , in specific implementation, in the unit steel pipe scaffolding between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com