Preparation method for ultrahigh-content malt syrup

A maltose syrup and content technology, applied in fermentation and other directions, can solve the problems of difficult practical operation, difficult to complete the reaction, and reduce the content, and achieve the effect of diversified adjustment means and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Use corn starch as raw material, add water to make slurry, adjust the dry matter concentration of the slurry to 20%, adjust the pH value to 5.8, add 0.3g / kg DS high temperature resistant amylase to the slurry;

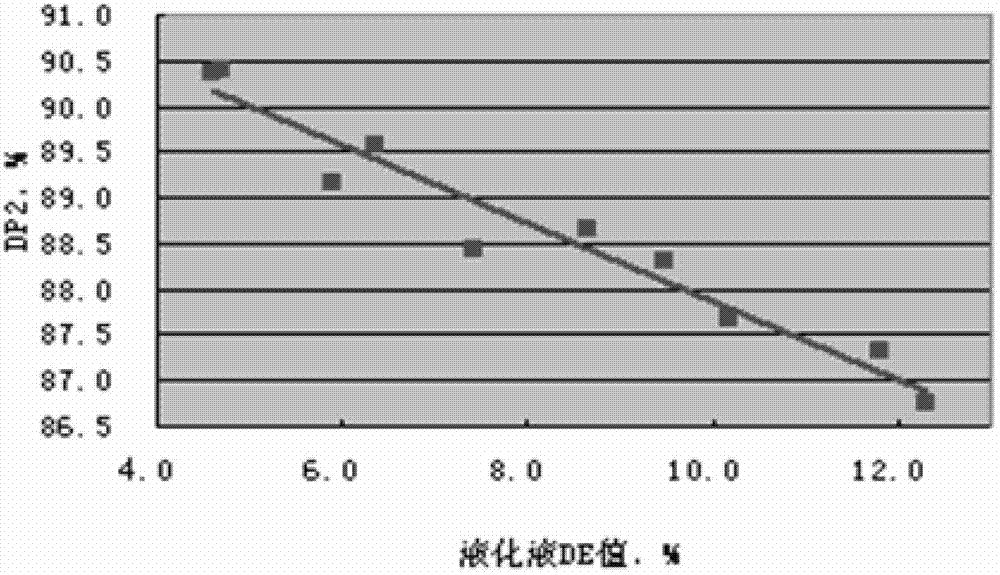

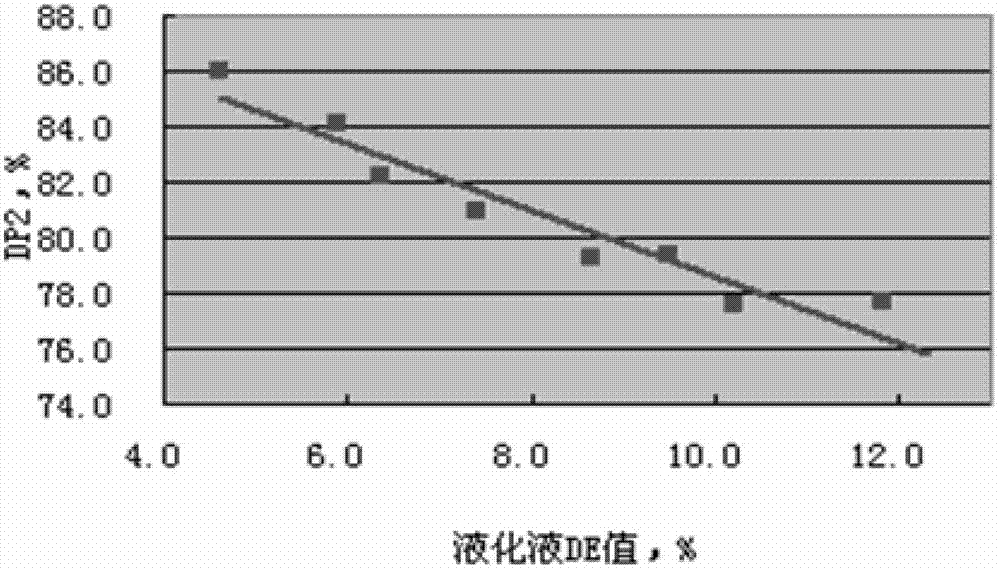

[0030] (2) Use a digester to cook the above slurry at 108°C for 5 minutes. During the cooking process, confirm that the pressure difference across the heating zone of the digester (digester raw material feed pressure - clinker discharge pressure) is not less than 2 kg. Starch paste was obtained after cooking, and the starch paste was liquefied and hydrolyzed. The liquefaction time was 30, 60, 90, 120 and 150 minutes respectively. The obtained liquefied liquid was subjected to iodine test, and the filtration speed and DE value were measured. The results are shown in Table 1. , to obtain maltodextrin aqueous solution;

[0031] (3) Adjust the pH value of the above maltodextrin aqueous solution to 5.0, add glucoamylase and use double-enzyme method or three-enzym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com