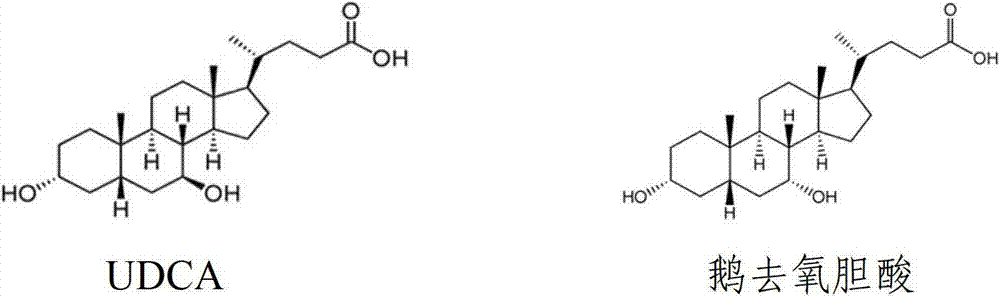

Method for respectively recovering ursodesoxycholic acid and chenodeoxycholic acid from ursodesoxycholic acid waste mother liquor

A technology for ursodeoxycholic acid and chenodeoxycholic acid, which is applied in the field of recovering ursodeoxycholic acid and chenodeoxycholic acid respectively, can solve the problem of low yield of ursodeoxycholic acid, waste of active ingredients, and refining cost Advanced problems, to achieve the effect of easy large-scale industrial production, high recovery efficiency, and good product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take 100g of the waste mother liquor refined by ursodeoxycholic acid, add 2L of pure water and 10g of sodium hydroxide, heat to 65°C and stir until dissolved, then add dilute hydrochloric acid with a concentration of 50% by mass to adjust the pH value to 8.0, The temperature was lowered to 25°C, and the solution was passed through ultrafiltration and nanofiltration membranes with a molecular weight cut-off of 10K to remove a large amount of impurities and color to obtain a clarified filtrate.

[0035] Add dilute hydrochloric acid with a mass percent concentration of 50% to the obtained filtrate, acidify to pH 3.0, continue stirring for 30 minutes, filter and dry to obtain total cholic acid solids including ursodeoxycholic acid and chenodeoxycholic acid.

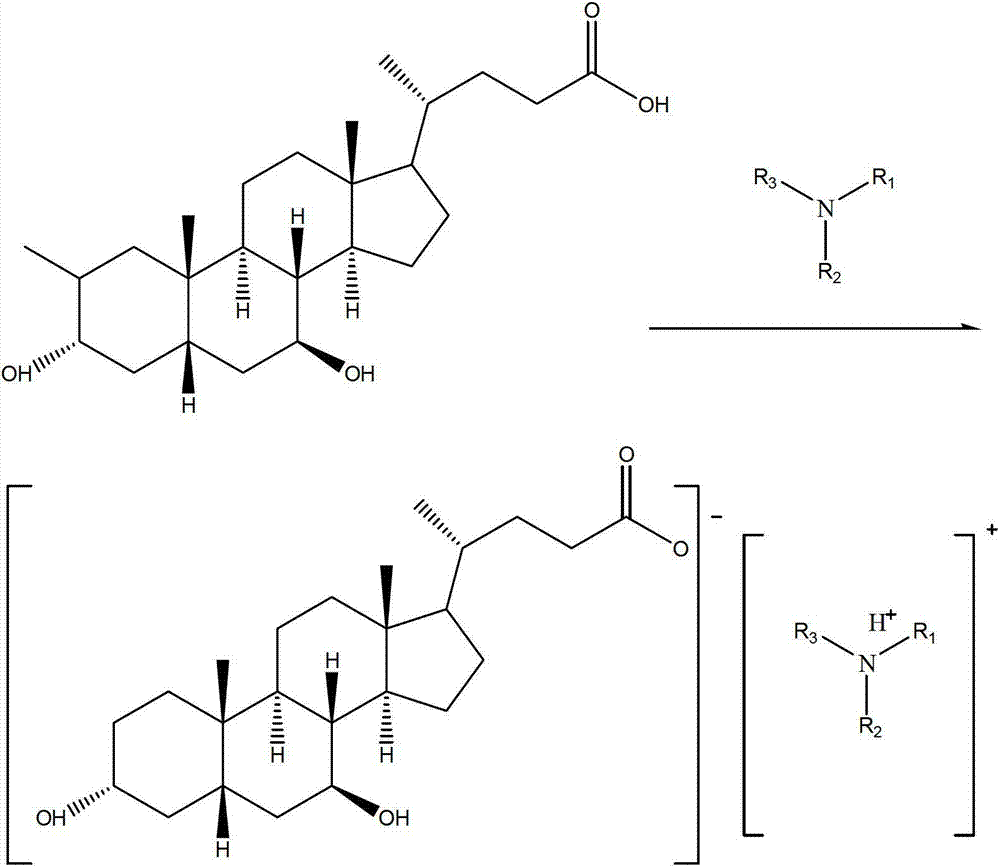

[0036] Add 10 times the weight of total bile acid into sec-butanol and 20% of its weight into triethylamine, heat and reflux for 2 hours, then slowly cool down to about 20°C to obtain white ammonium ursodeoxycholic acid...

Embodiment 2

[0041] Take 200g of the waste mother liquor refined by ursodeoxycholic acid, add 2L of pure water and 20g of sodium hydroxide, heat to 65°C and stir until dissolved, add dilute hydrochloric acid with a concentration of 40% by mass to adjust the pH value to 7.0, and cool down to 25 ℃, the solution was passed through the ultrafiltration membrane and the nanofiltration membrane with a molecular weight cut-off of 3K to remove a large amount of impurities and color, and a clear filtrate was obtained.

[0042]Dilute hydrochloric acid with a concentration of 50% by mass was added to the obtained filtrate, acidified to a pH value of 2, filtered and dried to obtain total cholic acid solids including ursodeoxycholic acid and chenodeoxycholic acid.

[0043] The total bile acid was added into acetone and 20wt% diisopropylethylamine according to 15 times its weight, and after heating and refluxing for 3 hours, it began to slowly cool down to about 20°C, and a white ammonium ursodeoxycholic ...

Embodiment 3

[0048] Take 200g of the waste mother liquor refined by ursodeoxycholic acid, add 4L of pure water and 10g of sodium hydroxide, heat to 65°C and stir until dissolved, add dilute hydrochloric acid with a concentration of 60% by mass, adjust the pH value to 7.0, and cool down to At 25°C, pass the solution through an ultrafiltration membrane and a nanofiltration membrane with a molecular weight cut-off of 1K to remove a large amount of impurities and color to obtain a clear filtrate.

[0049] Dilute hydrochloric acid with a concentration of 50% by mass was added to the obtained filtrate, acidified to a pH value of 3.0, filtered and dried to obtain total cholic acid solids including ursodeoxycholic acid and chenodeoxycholic acid.

[0050] Add the total bile acid to ethyl acetate and 20wt% ethylenediamine according to 10 times its weight, heat and reflux for 2.5 hours, then slowly cool down to about 20°C to obtain white ammonium ursodeoxycholic acid precipitate, filter, The filter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com