Preparation method of graphite oxide with high degree of oxidation and high dispersibility

A high-dispersion, oxidized stone technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of low oxidation degree of graphite oxide, increase graphite pre-oxidation process, prolong low-temperature reaction time, etc., and achieve raw material Low cost, shortened post-processing time, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The method for preparing highly dispersible graphite oxide by using Xinghe 325 mesh flake graphite comprises the following preparation steps:

[0031] 1. Put the beaker in an ice-salt bath. After the temperature in the beaker drops to -4°C, weigh 1 gram of Shuangxing 325 mesh flake graphite powder, add it to the beaker, and take 23ml of concentrated sulfuric acid with a mass percentage concentration of 98%. Slowly add to the beaker, and then add 0.5 grams of nitrate, the nitrate is sodium nitrate, put in the magnet;

[0032] 2. Set the stirring speed to 300 rpm, and stir and react at -4°C for 24 hours;

[0033] 3. After the low-temperature reaction is over, remove the ice-salt bath, soak the beaker in a water bath, and stir at 500 rpm. Weigh 3 grams of potassium permanganate and slowly add it to the concentrated sulfuric acid graphite powder solution within 5-10 minutes, and the temperature of the water bath is raised to 35°C for 4 hours until the solution becomes ...

Embodiment 2

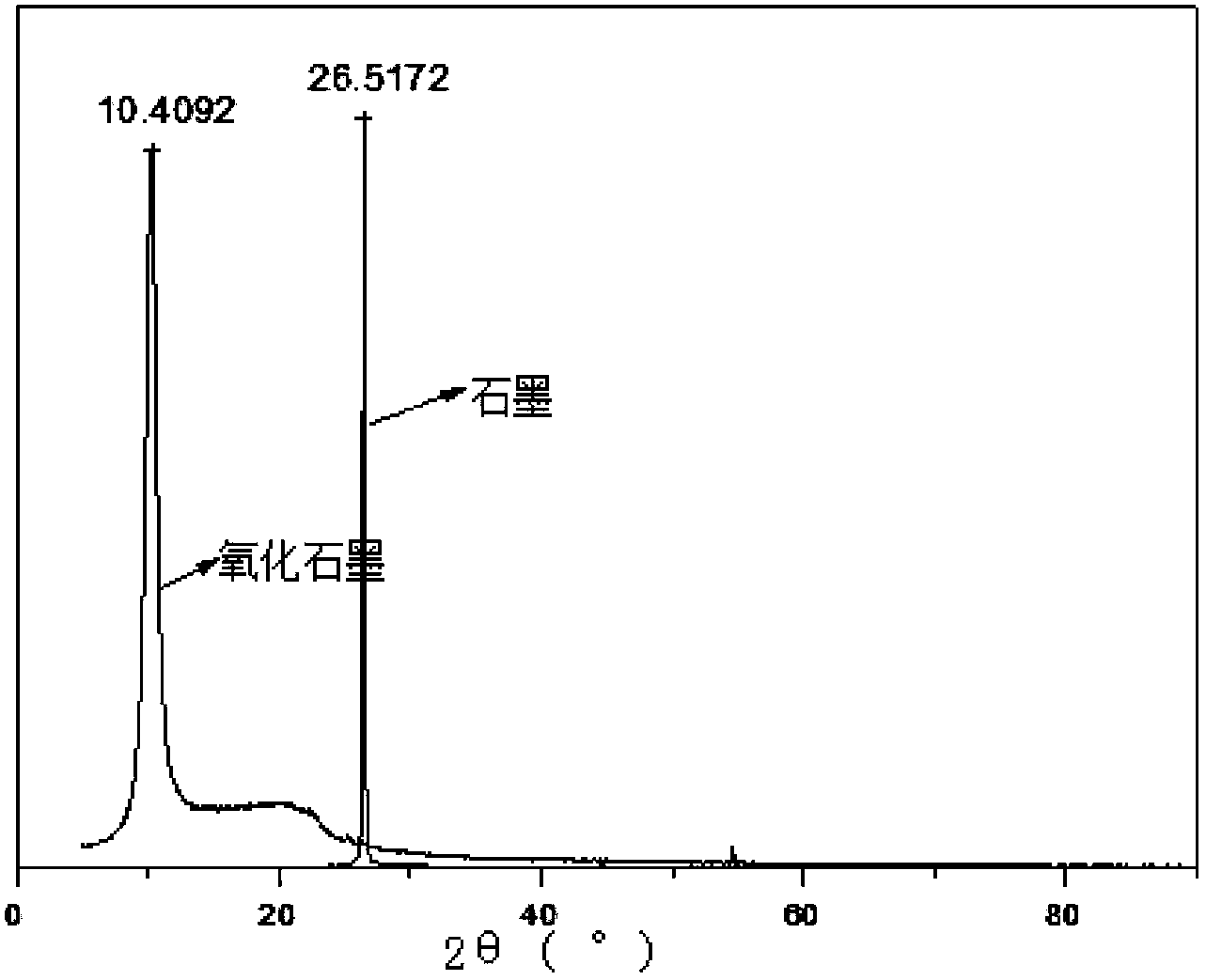

[0047] Example 2. Press the preparation method of embodiment 1, just change the amount of described potassium permanganate into 8 grams, obtain equally figure 2 , image 3 , Figure 4 As a result, the obtained graphite oxide was tested for elemental analysis, and the carbon-oxygen ratio of graphite oxide obtained was 0.96;

Embodiment 3

[0048] Embodiment 3. is pressed the preparation method of embodiment 1, just described nitrate is 0.5 gram potassium nitrate, obtains equally figure 2 , image 3 , Figure 4 As a result, the obtained graphite oxide was tested for elemental analysis, and the carbon-oxygen ratio of graphite oxide obtained was 0.96;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com