Cable Connector Assembly

A technology of cable connectors and components, applied in the direction of connection, parts of connection devices, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

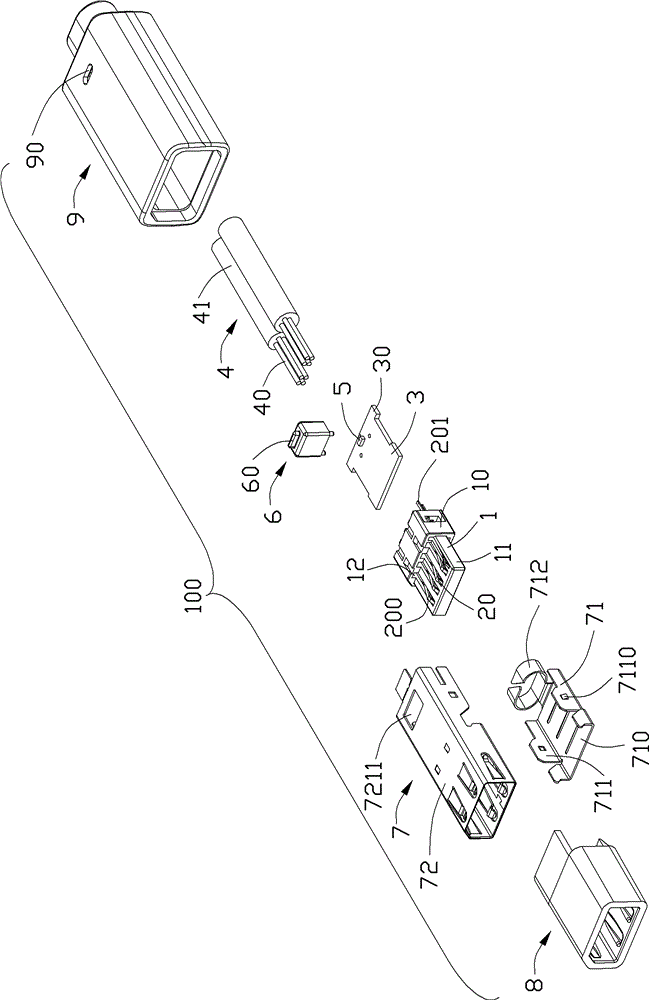

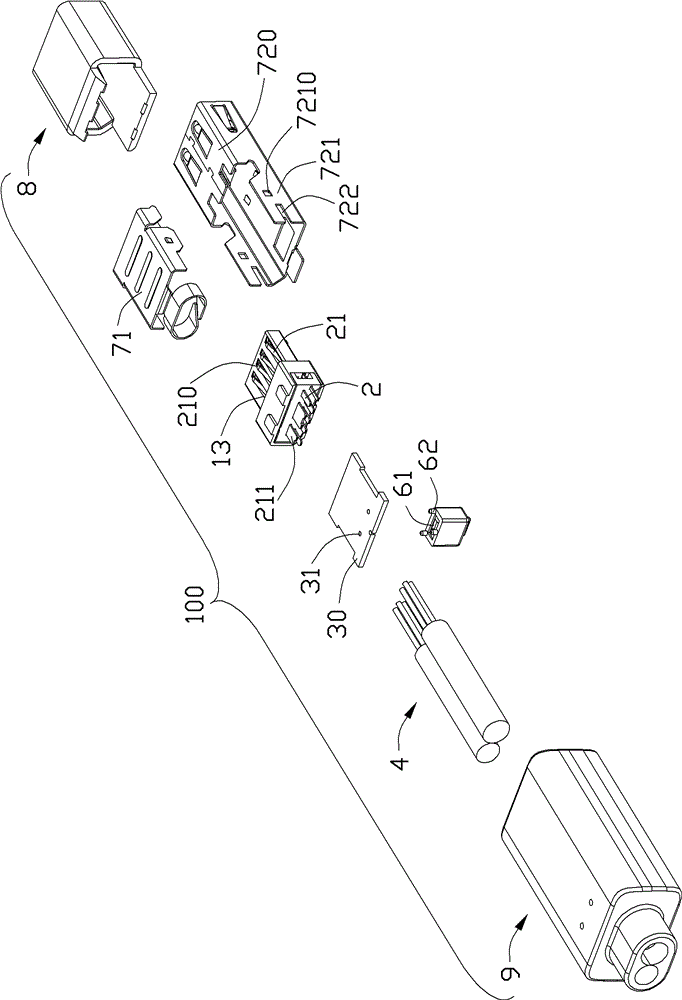

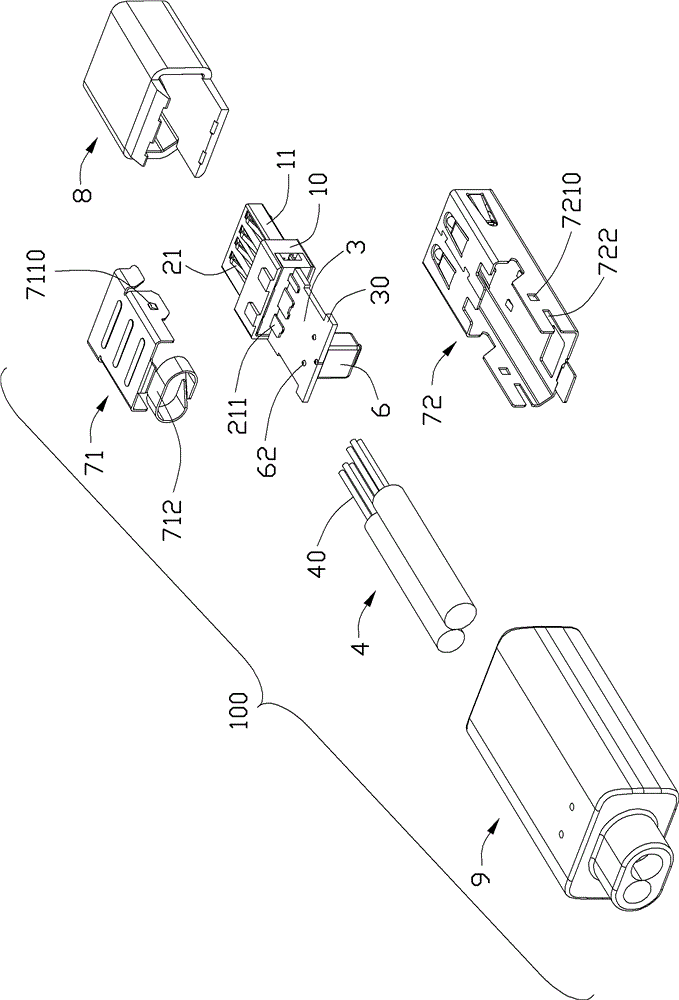

[0011] Please refer to Figure 1 to Figure 2 As shown, the cable connector assembly 100 of the present invention includes an insulating body 1, a conductive terminal 2 disposed in the insulating body 1, a printed circuit board 3 electrically connected to the conductive terminal 2, and a printed circuit board 3 electrically connected to the rear of the printed circuit board 3. The cable 4 , the LED 5 arranged above the printed circuit board 3 , the light pipe 6 arranged above the LED 5 , and the metal shell 7 covering the periphery of the insulating body 1 .

[0012] Please refer to Figure 1 to Figure 2 As shown, the insulator body 1 includes a main body 10 and a tongue 11 extending forward from the main body 10, and two rows of first holes respectively penetrating on the upper and lower surfaces of the tongue 11 are formed by recessing forward from the rear surface of the main body 10. The terminal receiving groove 12 and the second terminal receiving groove 13 . The conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com