Endurance test system for PCV (positive crankcase ventilation) valves

A technology of durability test and solenoid valve, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., which can solve the problems of inability to monitor the fully open/closed state of PCV valves, inconvenient replacement of consumable parts, and solenoid valves. Poor service life and other problems, to achieve the effect of easy replacement, fast action response time and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

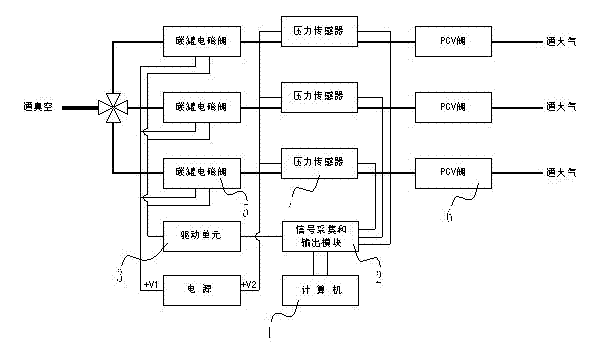

[0012] Such as figure 1 As shown, the present invention provides a PCV valve durability test system, including a computer 1, a signal acquisition and output module 2, a drive unit 3, a pressure sensor 4, a carbon tank control valve 5 and a PCV valve 6, wherein the carbon tank control valve 5 The air inlet end of the PCV valve 6 is connected to the air outlet end of the PCV valve 6 through a pipeline, the air outlet end of the carbon tank control valve 5 is connected to the vacuum, the air inlet end of the PCV valve 6 is connected to the atmosphere, and the pressure sensor 4 is installed between the carbon tank control valve 5 and the PCV valve 6 On the pipeline between them, the drive unit 3 is electrically connected to the canister control valve 5 and the signal acquisition and output module 2, the pressure sensor 4 is electrically conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com