A light bar, a light bar structure and a light bar packaging structure

A packaging structure and light bar technology, applied in lighting devices, lighting device parts, lighting and heating equipment, etc., can solve the problems of no protection mechanism, impact, high defect rate, etc. The effect of packaging efficiency and high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the accompanying drawings.

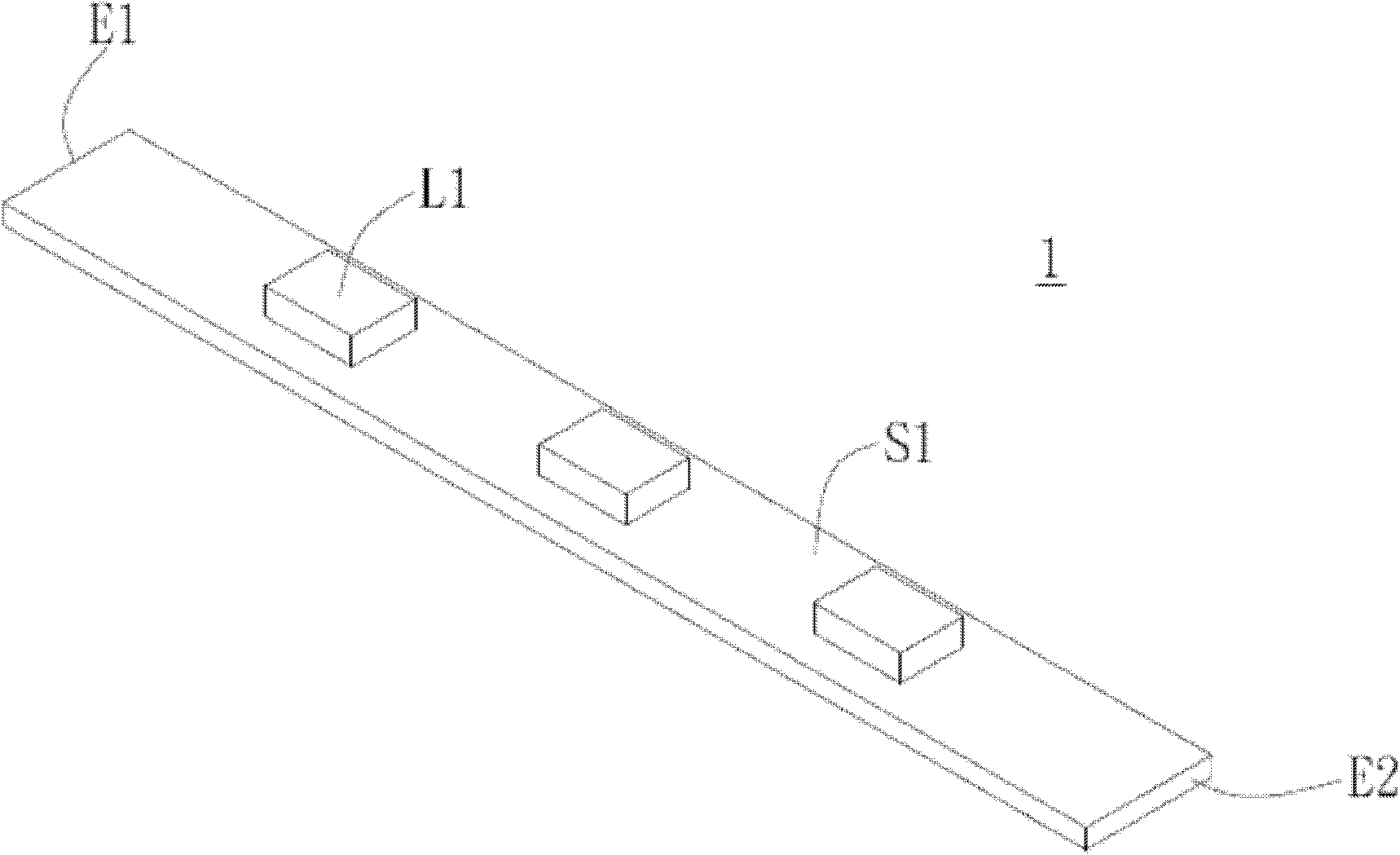

[0061] A specific embodiment of the invention is a light bar. In this embodiment, the light bar may be an LED light bar, but it is not limited thereto, and there is no specific limitation.

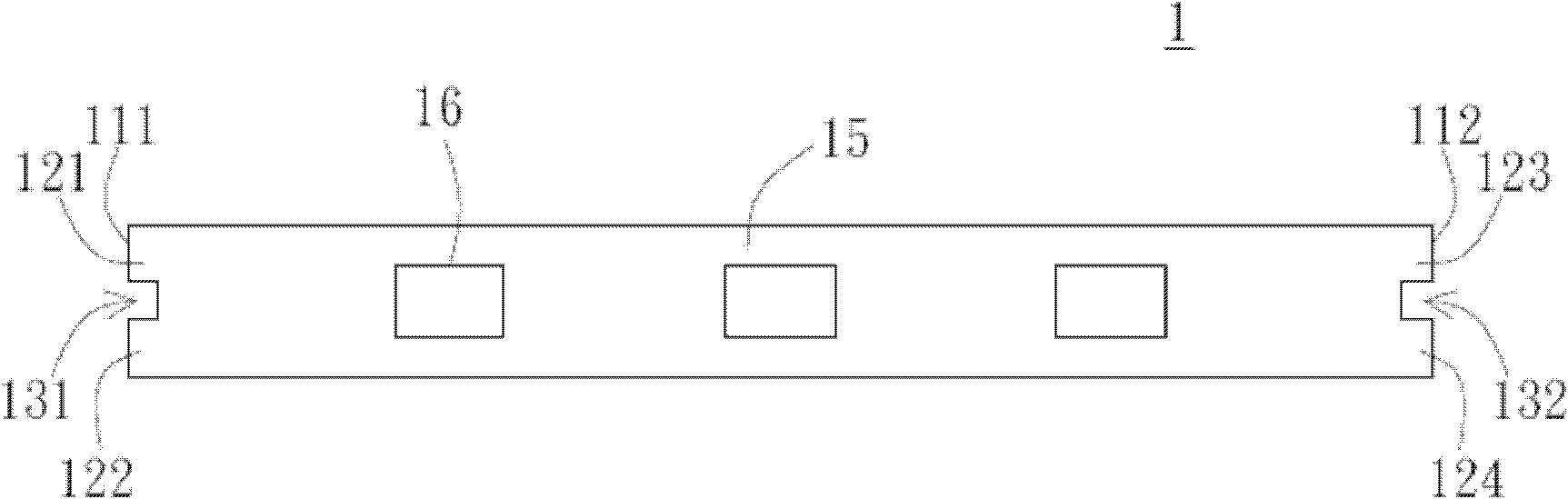

[0062] refer to figure 2 , figure 2 It is a top view of an embodiment of the light bar of the present invention. like figure 2 As shown, the light bar 1 includes a first substrate 15 , several light sources 16 , a first engaging portion 131 and a second engaging portion 132 . The first substrate 15 has a first edge 111 and a second edge 112 . The light source 16 is disposed on the first substrate 15 along the line connecting the first edge 111 and the second edge 112 . In this embodiment, the light source 16 is preferably a light emitting diode.

[0063] It should be noted that the first engaging portion 131 is disposed on the first end edge 111 and is recessed toward the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com