Integrated permanent air-storage energy accumulator

An accumulator and gas storage technology, which is applied in the direction of machinery and equipment, can solve the problems of high-pressure gas leakage, waste of manpower and material resources, failure of accumulators, etc., and achieve high reliability, save manpower and material resources, and facilitate storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

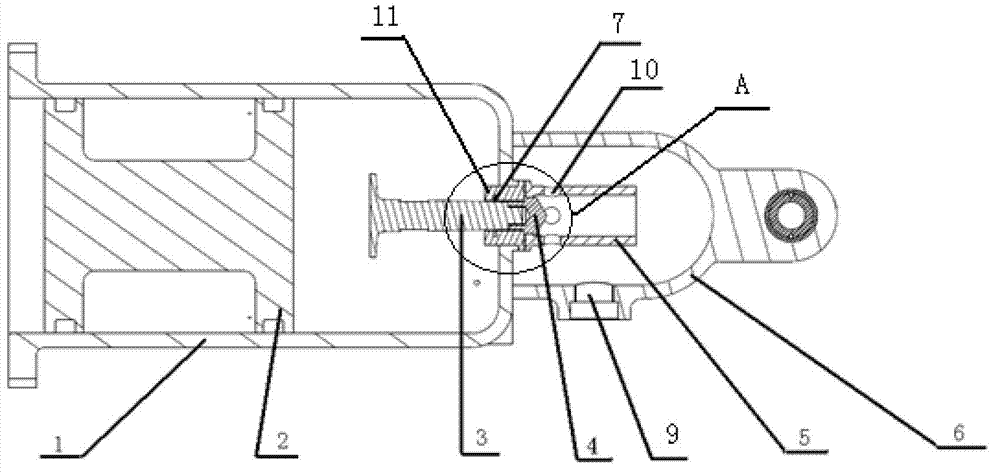

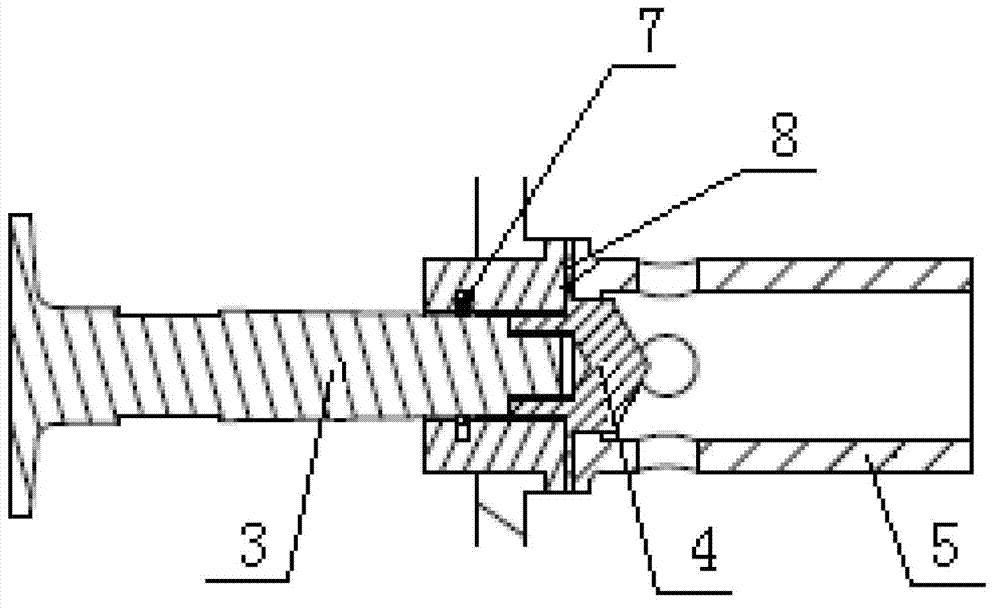

[0014] An integrated permanent gas storage accumulator provided by the present invention is introduced below in conjunction with the accompanying drawings:

[0015] Such as figure 1 with figure 2 As shown, the punch seat A11 is welded to the opening at one end of the accumulator housing 1, the high-pressure punch 4 is welded to the punch seat A11 through the sheet 8, and the punch seat B5 is welded to the high-voltage punch 4 through the sheet 8. There is a through hole 10 on the punch seat B5, one end of the punch rod 3 is fixed in the punch seat A11 through a U-shaped spring clamp, and the gas storage bottle 6 is set on the outside of the punch seat B5 and welded to the accumulator housing 1 Above, there is an accumulator piston 2 inside the accumulator housing 1 .

[0016] In order to meet the requirement of closing the gas storage cylinder 6, the high-pressure gas storage cylinder and the accumulator air chamber are welded into two independent cavities, and after the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com