Progressive-temperature-control fireproof separation board

A technology for insulation boards and insulation boards, which is applied in the direction of fire prevention, heat preservation, and building components. It can solve the problems of complex anchoring of insulation layers or insulation decorative panels, complex structure of insulation systems, and difficult quality control, so as to improve safety and earthquake resistance. The effect of convenient construction and small temperature fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

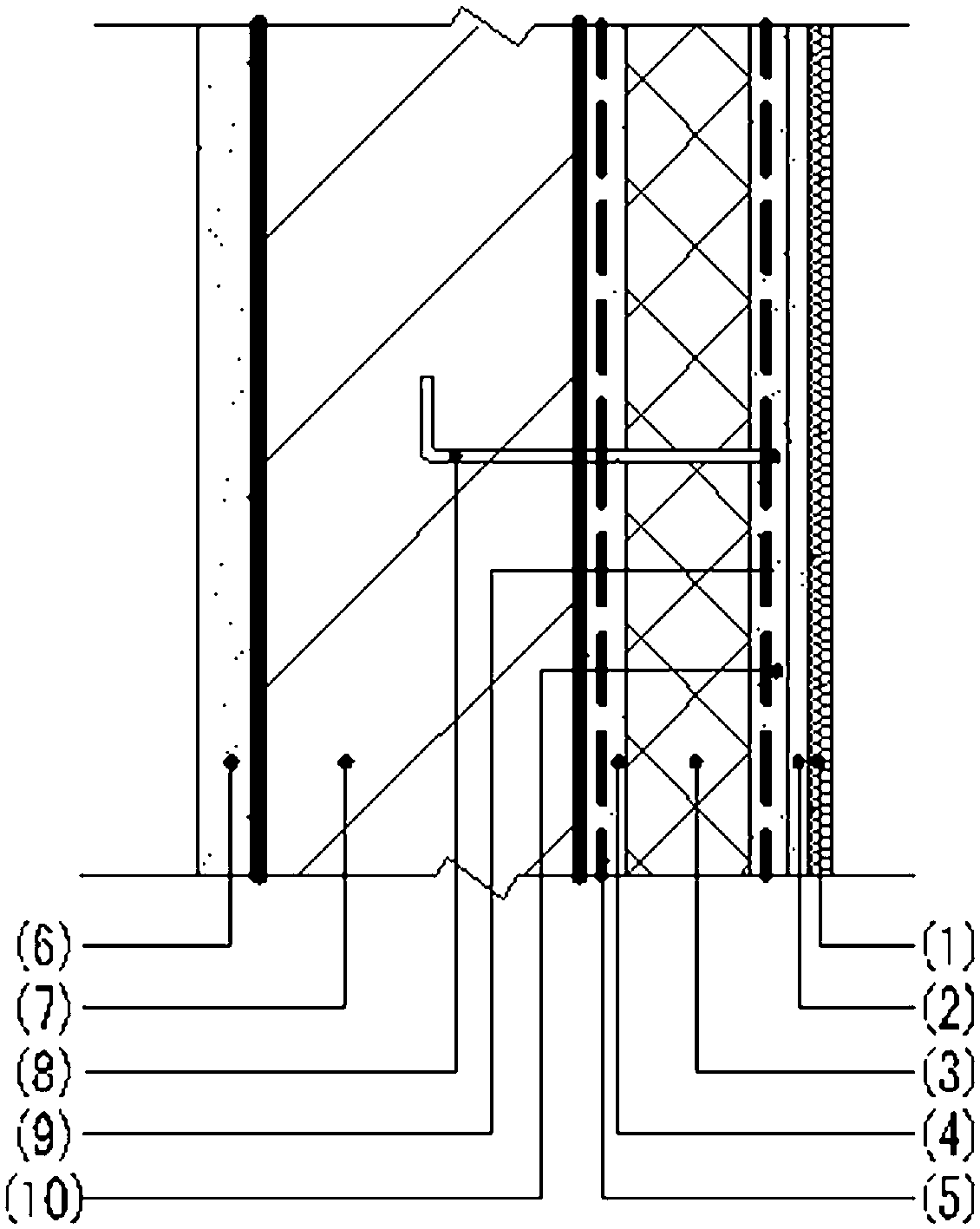

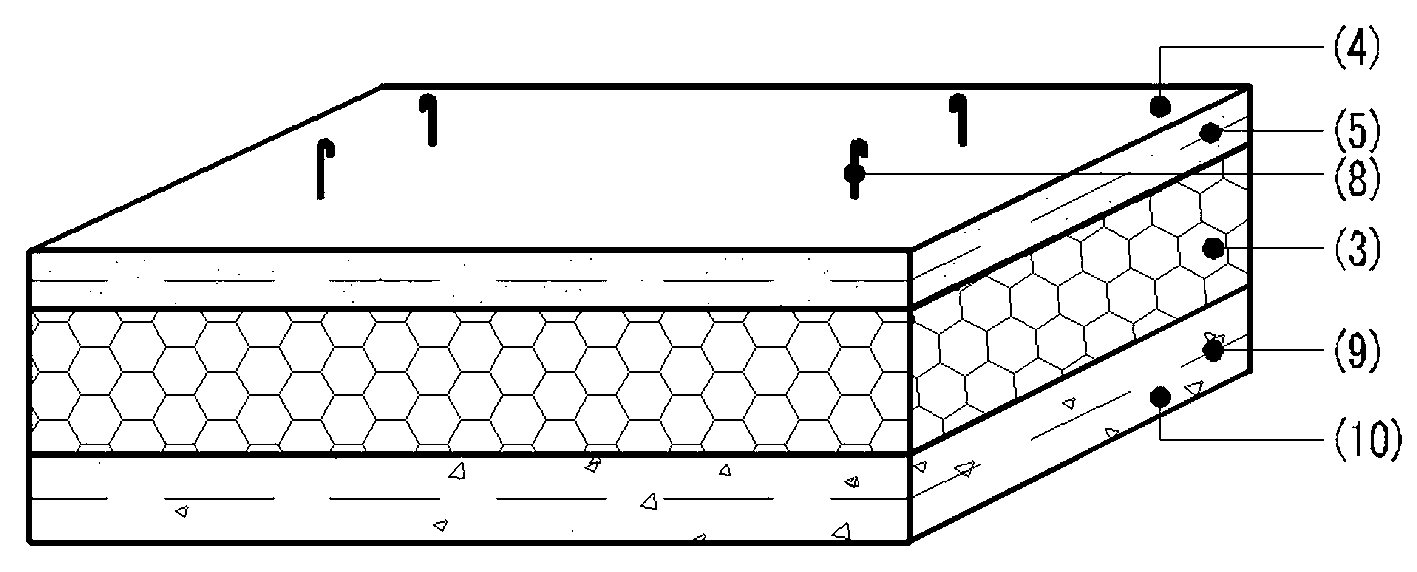

[0012] exist figure 2 In the process, pre-cast and pre-embed the tension reinforcement (8) on the outside of the steel wire mesh (9) in the high-strength hidden honeycomb latent heat concrete slab (10), then apply the coupling agent on the inside of (10), and paste the gradient temperature magnesium mud insulation board (3), apply coupling agent at (3) inner side again, paste reinforced cement board (4), complete the making of NCB module of the present invention. During specific implementation, in figure 1 , according to the actual location of the site, firstly set the reinforcement protection layer pad on the reinforcement cage of the wall / beam / column structural member (7), and then fasten the tie bar (8) of the NCB module to the wall / beam / column structure On the reinforcement cage of component (7), pour concrete. In addition, do special bonding layer (2) and finish layer (1) on the outside of (10), and do (7) interior wall surface and do inner plastering layer (6), finish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com