Low-noise lithium-based lubricating grease composition and preparation method thereof

A technology of composition and lubricating grease, applied in the direction of lubricating composition, petroleum industry, etc., can solve problems such as unfavorable operation and control, complex post-treatment process, etc., and achieve the effect of good bearing vibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

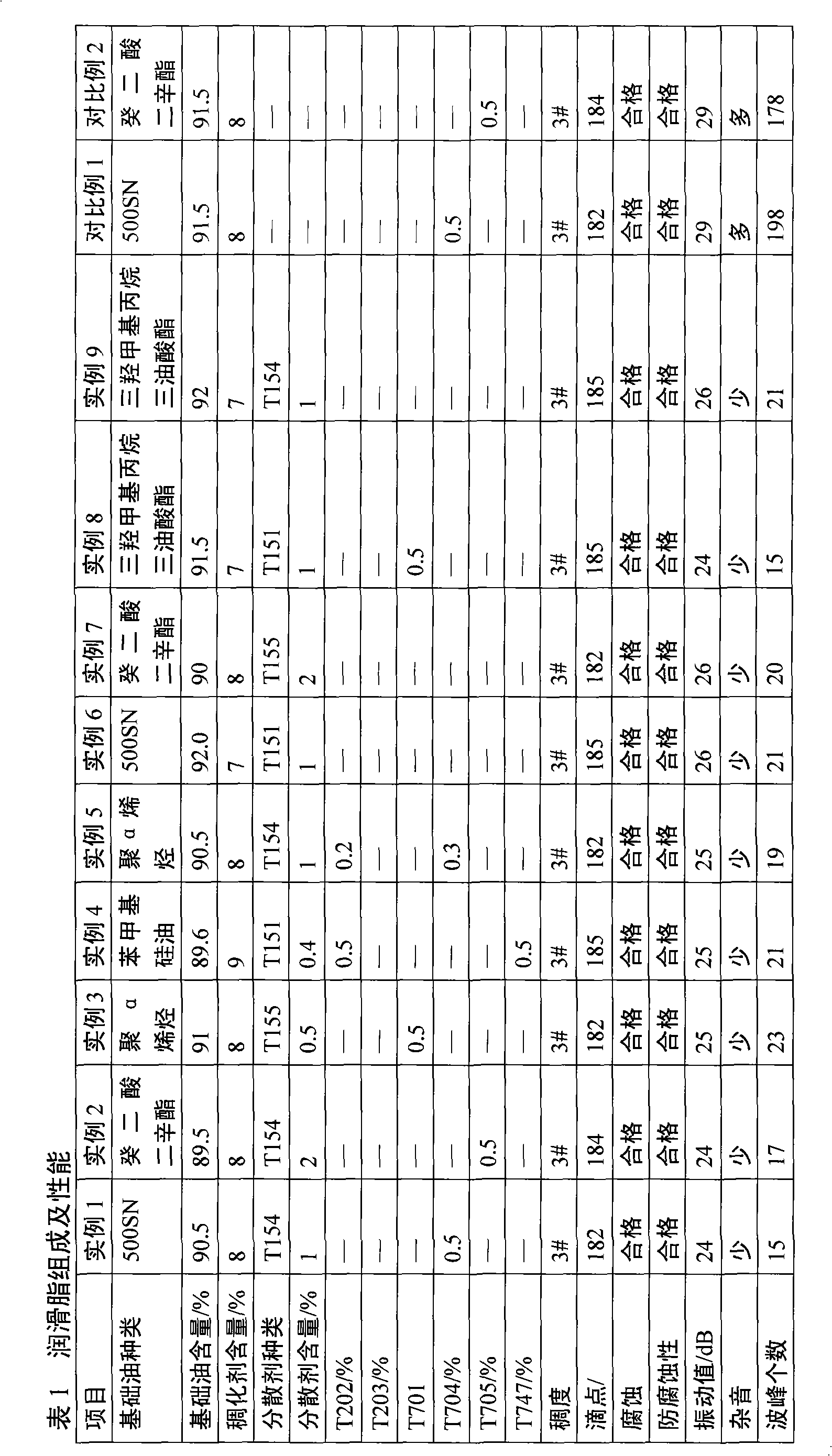

Examples

Embodiment 1

[0029] Add 30kg of 500SN, 8kg of dodecylhydroxystearic acid, 1kg of alkenylsuccinimide (code T154) into the reaction kettle, heat to 90℃, add 4kg of lithium hydroxide aqueous solution (1.12) between 15min and 40min kg lithium hydroxide+2.88kg water), heat up to 160℃, gradually add 30kg of 500SN, continue heating to 200℃, the material is completely melted, add 30.5kg500SN, start cyclic shear (pressure 0.5MPa~0.7MPa) to cool down, temperature When the temperature is lowered to 100°C, 0.5kg T203 and 0.5kg T704 are added, and a sample of lubricating grease is obtained from the kettle.

Embodiment 2

[0031] Add 60kg of dioctyl sebacate, 8kg of lithium dodecyl stearate, and 2kg of dienyl succinimide (code T154) into the reaction kettle, and gradually stir and heat to 210°C. Lithium fatty acid is completely melted. Gradually add 29.5kg of dioctyl sebacate, start to circulate shearing and cooling (pressure 0.5MPa~0.7MPa), when the temperature is 100℃~120℃, add 0.2kg T202, 0.3kg T705, and take it out of the kettle Prepare grease samples.

Embodiment 3

[0033] Add 30kg of poly alpha olefin oil (viscosity 5.9mm at 100℃) into the reactor 2 / s), 8kg of dodecanoic acid, 0.5kg of polyalkenyl succinimide (code T155), heated to 85℃, add 5kg of lithium hydroxide aqueous solution (1.12kg of hydroxide Lithium+3.88kg water), heat up to 165℃, and gradually add 30kg poly-α olefin oil (100℃ viscosity 5.9mm 2 / s), continue to heat up to 200℃, the material is completely melted, add 31kg of poly-α olefin oil (100℃ viscosity 5.9mm 2 / s), start cyclic shearing and cooling (pressure 0.5MPa~0.7MPa), when the temperature is 110℃, add 0.5kg T701 and take out the kettle to prepare the grease sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com