Assembling line for glass-fiber reinforced plastic windows

An assembly line, FRP technology, applied in the direction of assembly machines, other manufacturing equipment/tools, metal processing equipment, etc., can solve problems such as low efficiency, difficult operation of the assembly process, and impact on production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can more clearly understand how to practice the present invention. It should be understood that while the invention has been described in connection with preferred specific embodiments thereof, these embodiments are intended to illustrate, not limit, the scope of the invention.

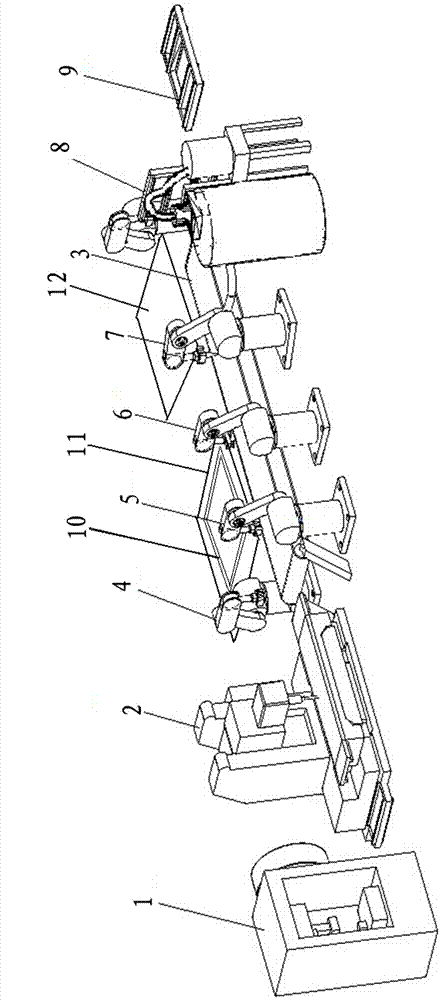

[0025] Such as figure 1 As shown, the figure includes:

[0026] punching machine 1, used for cutting the building profiles;

[0027] CNC milling machine 2, used for drilling the cut building profiles;

[0028] The conveyor belt 3 is used for conveying the drilled building profiles;

[0029] The first workbench 11 is located at the feed end of the conveyor belt 3, and the upper surface of the first workbench 11 is provided with a cavity 10 corresponding to the shape and size of the building profile, which is used to place the drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com