On-line SPM generating system and control method thereof

A generation system, flow control technology, applied in ratio control, cleaning method and utensils, non-electric variable control, etc., can solve the problems of reduced reflectivity and damage of surface material ruthenium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

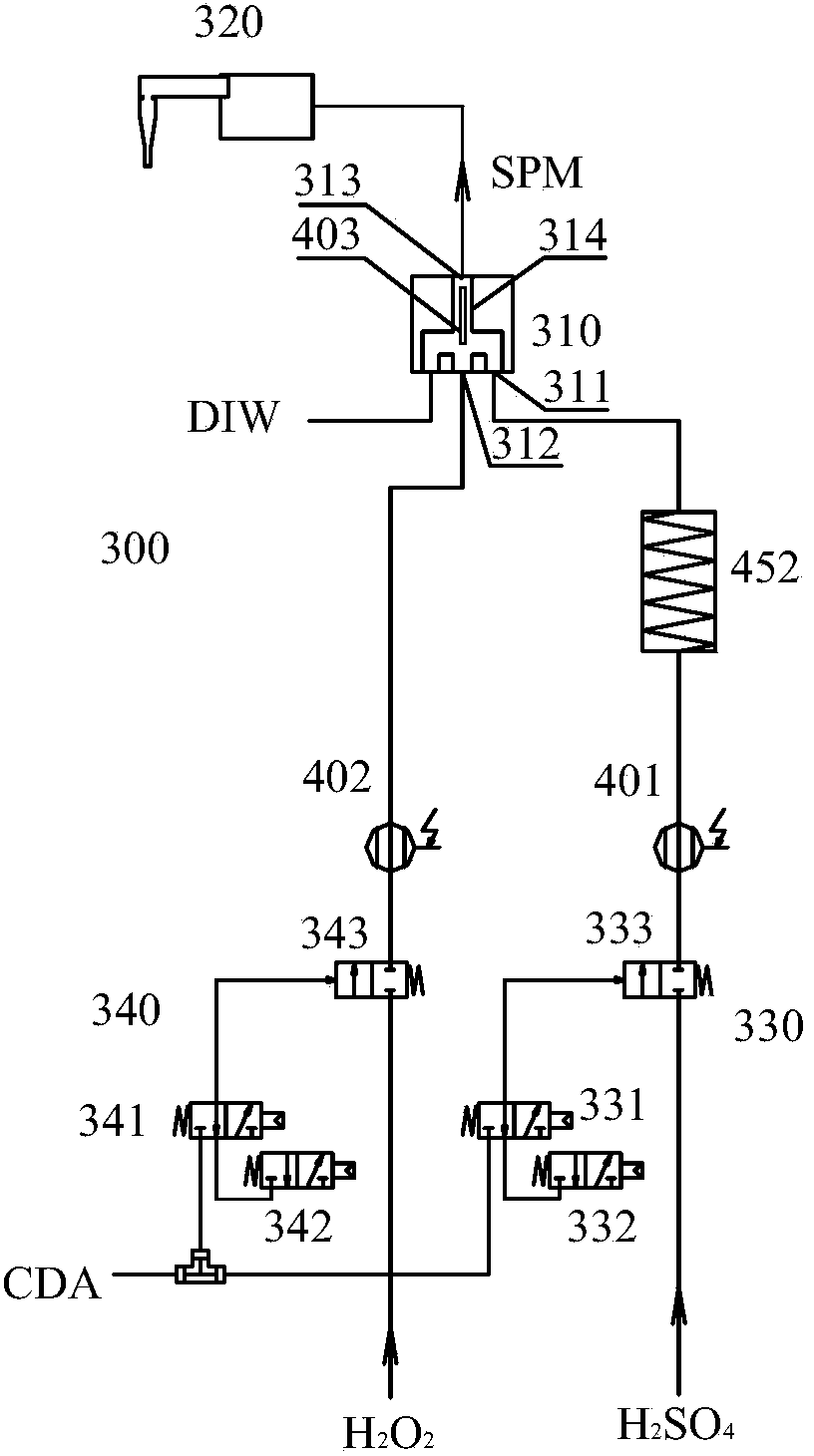

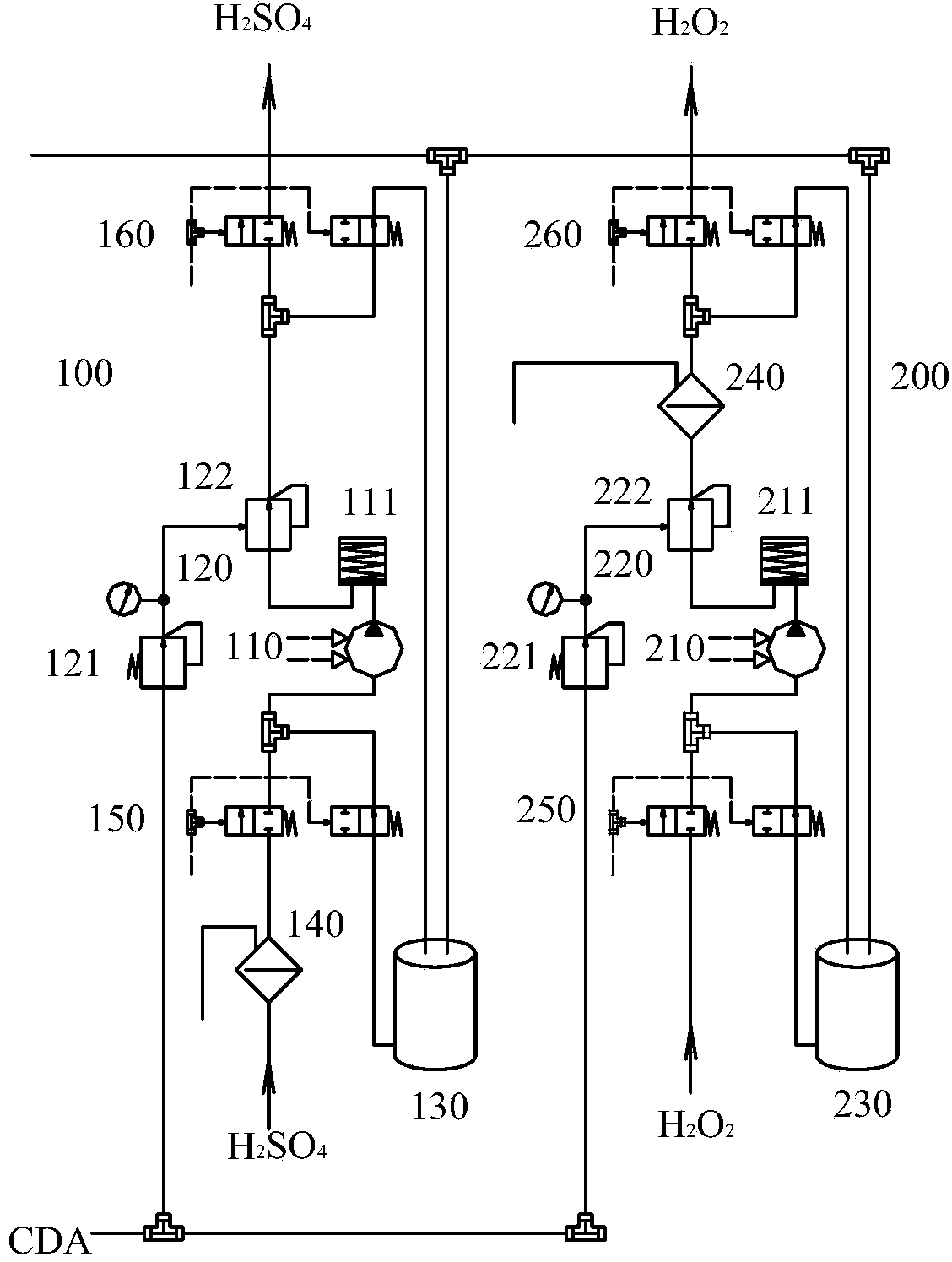

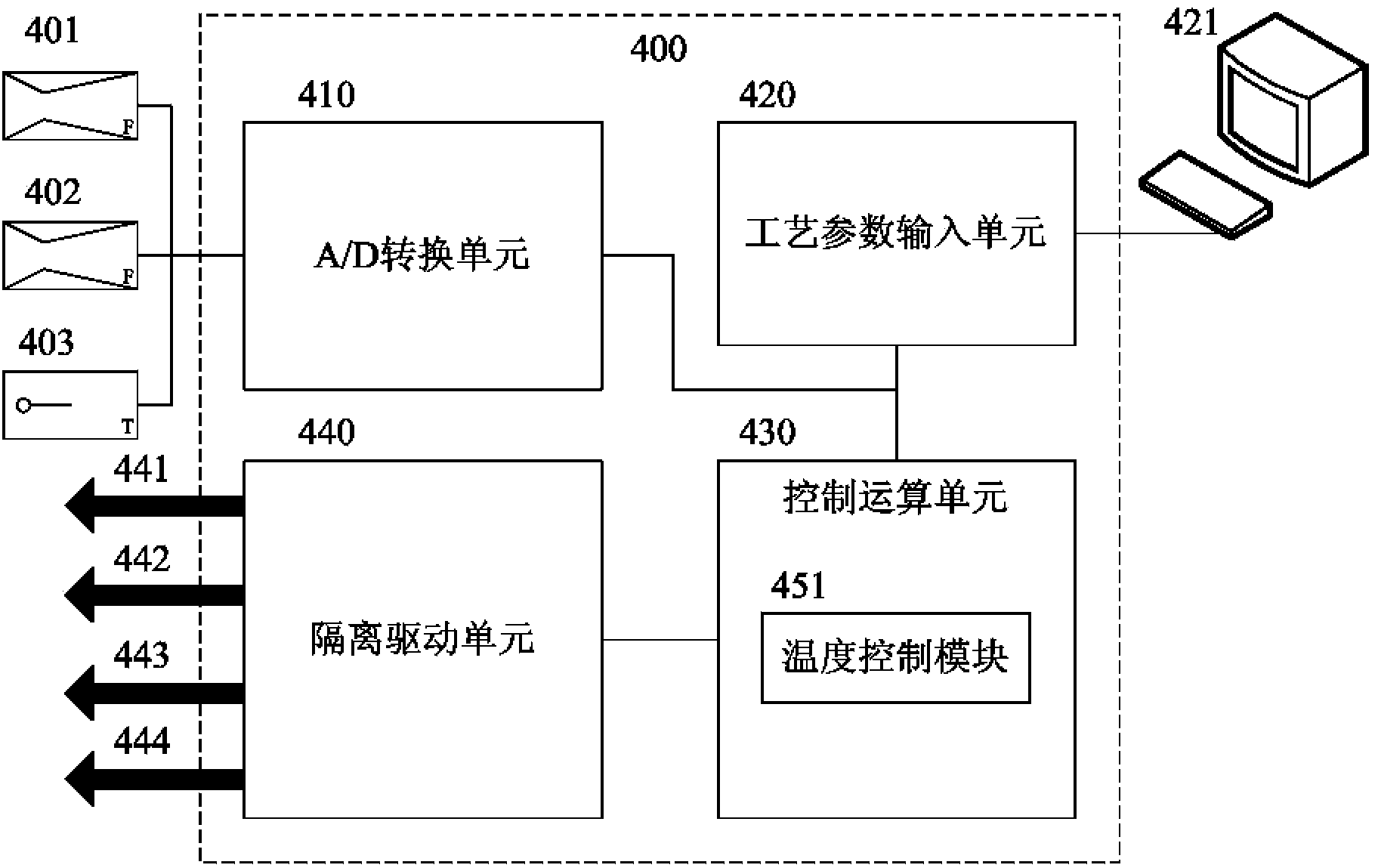

[0042] Online SPM generation system of the present invention such as figure 1 and figure 2 shown, including H 2 SO 4 Supply unit 100, H2 o 2 The supply unit 200, the SPM mixing spray unit 300 and the control unit 400, the functional block diagram of the control unit can be found in image 3 .

[0043] h 2 SO 4 The supply unit 100 includes H 2 SO 4 Flow control element 120, H 2 SO 4 flow control element 120 through H 2 SO 4 The delivery pipeline is connected to the SPM mixing spray unit 300;

[0044] h 2 o 2 The supply unit 200 includes H 2 o 2 flow control element 220, the H 2 o 2 flow control element 220 through H 2 o 2 The delivery pipeline is connected to the SPM mixing spray unit 300;

[0045] The SPM mixing spray unit 300 includes an SPM mixing element 310 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com