Gear transmission optical fiber coloring printing ink blender

A coloring ink, gear transmission technology, applied in mixer accessories, mixers, dissolving and other directions, can solve the problems of unstable rolling, uneven mixing quality, and no solution to temperature adjustment and control, so as to improve the quality of mixing, improve adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

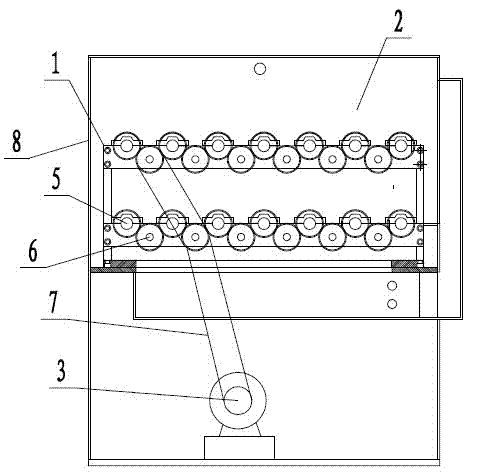

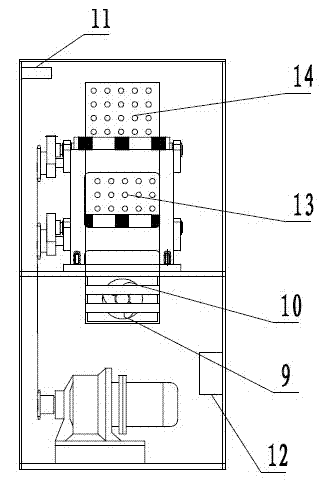

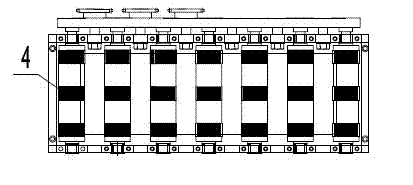

[0018] see Figure 1-Figure 4 In this embodiment, the gear-driven optical fiber coloring ink mixer includes a bracket 1, a roller device 2, a motor 3, a transmission and a temperature control module, the motor 3 is connected to the transmission, and the bracket 1 is provided with a two-layer roller device 2, and the roller device 2 includes a roller 4 , the first gear 5, the second gear 6, the rollers 4 of each layer of roller group are evenly distributed in parallel and are installed on the bracket 1 through the bearings arranged at both ends of the roller 4, and the first gear 5 is fixed on one side of the roller 4, A second gear 6 is arranged between two adjacent first gears 5, and the second gear 6 meshes with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com