Coffee aroma-containing composition

A composition and aroma technology, applied in the directions of coffee spice, coffee, coffee extraction, etc., can solve the problems of aroma, flavor satisfaction, flavor change, bitterness, increase of degraded components, etc., and achieve enhanced flavor, strong aroma, aroma and flavor. Balancing difficult effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The manufacture of embodiment 1 fermented coffee beans (1)

[0063] Fermented coffee beans are manufactured through the following processes:

[0064] 1) A steam treatment process in which coffee cherries are steamed for 15-30 seconds at 90-110°C,

[0065] 2) The process of cooling to 30-40°C,

[0066] 3) Adding 0.05 to 0.5% by weight of adipic acid or lactic acid per unit weight of coffee cherries to adjust the pH of the coffee cherries to pH 3 to 4

[0067] 4) Simultaneously with or after the pH adjustment step, a microorganism attachment step for attaching fermentation microorganisms is performed,

[0068] 5) Carry out the cultivation process at 30-40°C for 48-72 hours,

[0069] 6) A drying process in which the cultivated coffee cherries are dried,

[0070] 7) The process of separating and refining coffee pulp from coffee seeds to obtain fermented coffee beans.

[0071] That is, 100 kg of coffee fruit is prepared, and the above-mentioned process 1) is carried o...

Embodiment 2

[0081] The manufacture of embodiment 2 fermented coffee beans (2)

[0082] In Guatemala, green coffee beans are usually refined from coffee cherries using a water-washing process. After the harvested fruit is put into a water tank to remove impurities, it is put into a pulp removal machine to remove the pulp, and then put into the water tank again to remove the mucus attached to the endocarp. After that, it is dried in the sun or mechanically dried for shelling. This is because the cultivation site is on the slope of a mountain, and there is no place to spread and dry the fruits after harvesting, so it is an inevitable method.

[0083] On the other hand, Brazil and the like have vast flat land where a large amount of fruit can be dried at one time, and the harvesting period is a dry season, so there is no need to worry about rain, so non-washing (also called natural) refining is carried out. That is, the harvested fruit is directly spread on the square and dried in the sun,...

Embodiment 3

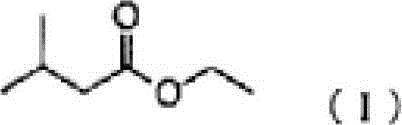

[0085] Embodiment 3 Preparation of compositions containing fragrance

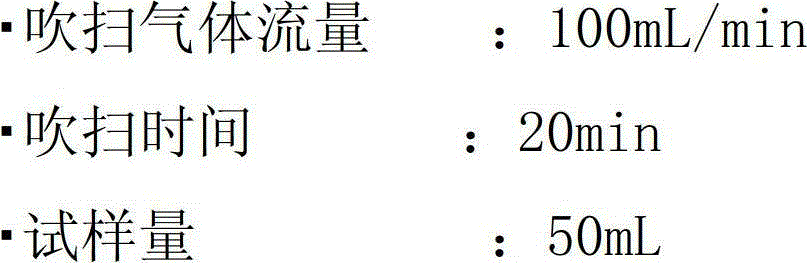

[0086] 50 kg each of the roasted and fermented coffee beans produced in Example 1 (sample 1) and the roasted and fermented coffee beans produced in example 2 (sample 4) were put together with 450 kg of room temperature water and pulverized by a wet grinder. The average particle diameter of the obtained pulverized particles was about 800 μm. This slurry is supplied to the SCC extraction device (Flavourtech company, M1,000 type) at a speed of 500L / hr. The proportion of aroma-containing condensate recovered was about 5%. The obtained condensate was cooled to 5° C. to obtain an aroma-containing condensate (aroma-containing composition) (invention products 1 and 2). The Brix values were all 0.19, and the concentrations of isovaleric acid in the compositions were 2.3 ppm and 380 ppb, respectively. In addition, the concentration of isovaleric acid in the composition was measured by the following method. A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com