Sewing machine table with cloth alignment function

An alignment function, technology of sewing machines, applied in the direction of sewing machine components, cloth feeding mechanism, sewing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

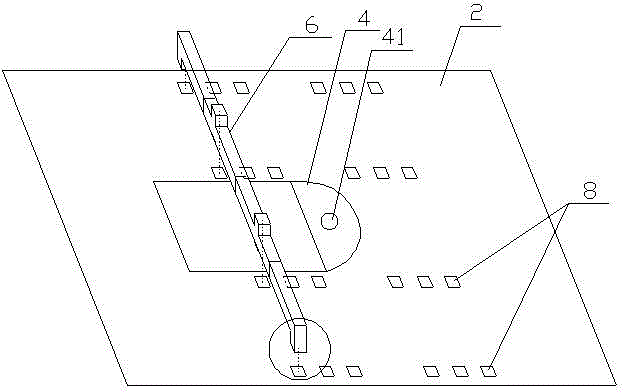

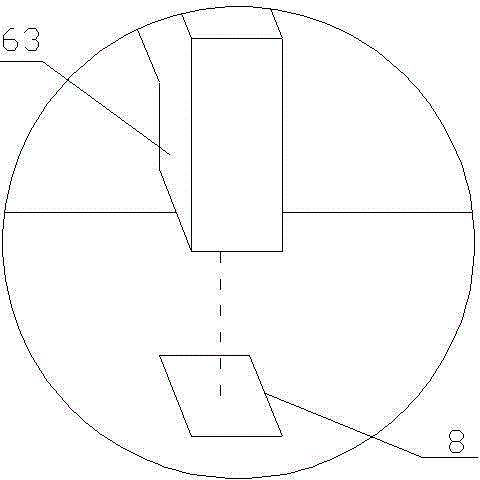

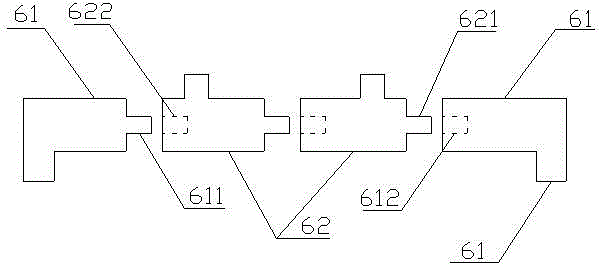

[0016] Such as Figure 1-3 As shown, a sewing machine bedplate with cloth alignment function of the present invention includes a flat body 2, and a needle plate 4 embedded in the body 2 with pinholes 41, and a needle plate 4 is provided near the body 2. There are 6 pairs of grooves 8, and a baffle plate 6 perpendicular to the body 2 is provided along the cloth passing direction. The baffle plate 6 is formed by combining and plugging 4 splicing plates, and each of the two ends is called an end splicing plate 61, and the middle ones are respectively called the splicing plates 62 in the middle. Each of the splicing plates extends transversely, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com