Product inspection turning device for continuous sterilizer

A technology of turning device and visual inspection device, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve the problems of difficulty in meeting large-scale production, inconsistencies anyway, and insufficient processing capacity of the assembly line, so as to save manpower, accurately detect products, and quickly The effect of flipping the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Exemplary embodiments according to the present invention will be described in detail below with reference to the accompanying drawings. Here, it should be noted that, in the drawings, the same reference numerals are assigned to components having substantially the same structure and function, and redundant descriptions on components that are substantially the same are omitted in order to make the description more concise.

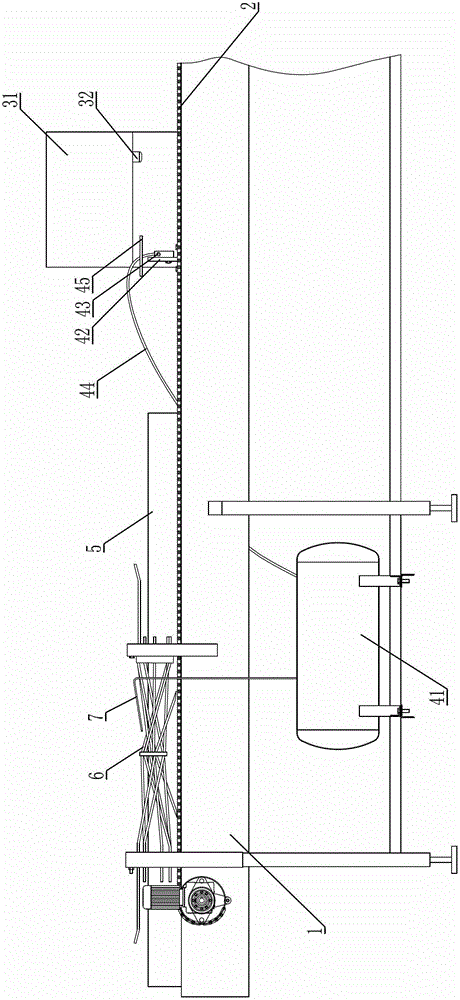

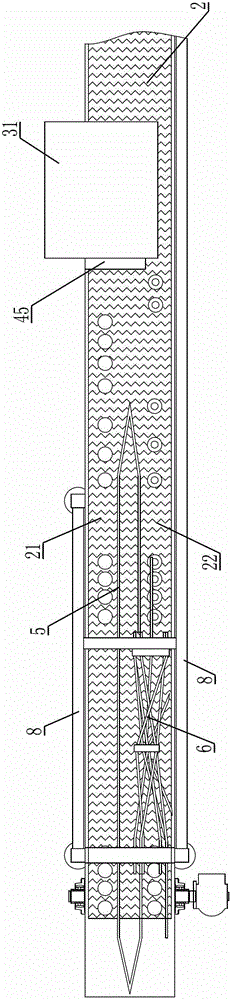

[0018] like figure 1 and figure 2 As mentioned above, the continuous sterilizer product detection and turning device includes a guide table 1, on which a product conveying network chain 2 is installed, and along the conveying direction of the product conveying network chain 2, the product conveying network chain 2 A visual detection device, a product separation device and a product separation device are provided in sequence, and a product separation control device is connected between the visual detection device and the product separation device; O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com