Automatic repair welding flexible positioner of manual-operation pallet truck

A manual pallet truck and positioner technology, applied in the field of flexible positioners, can solve the problems of affecting the quality of welding processing, poor working environment, high labor intensity, etc., to improve welding quality and production efficiency, save processing site area, The effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

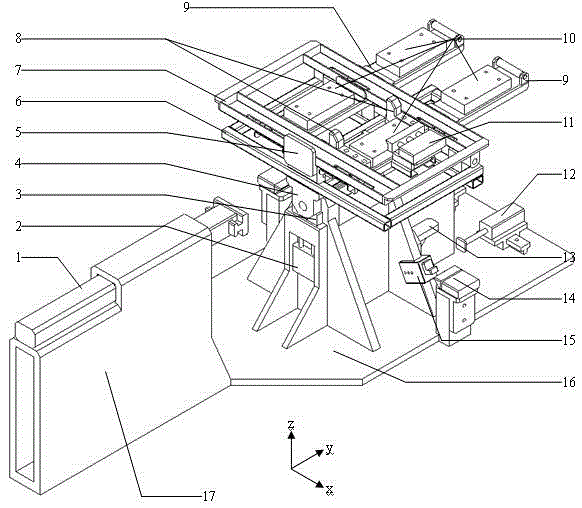

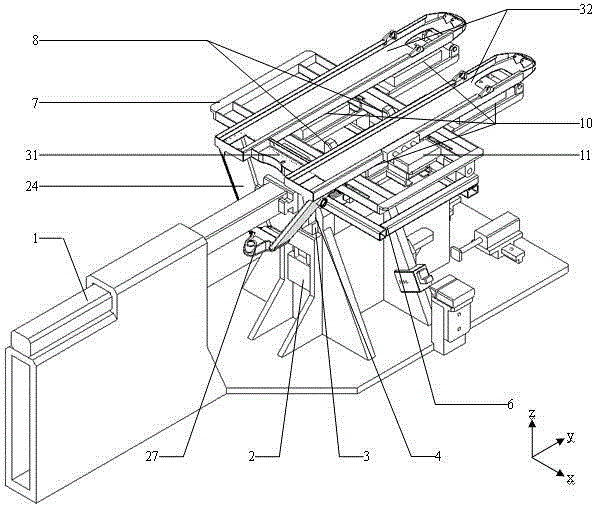

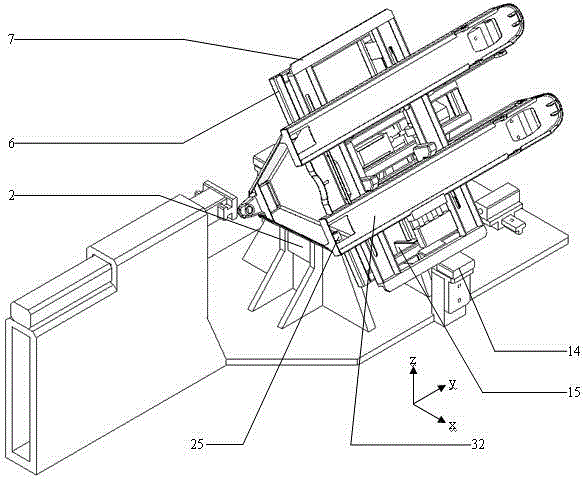

[0027] The present invention will be further described below in conjunction with accompanying drawing and example, for convenience of explanation, coordinate system definition is as follows figure 1 and Figure 5 As shown, the width installation direction of the manual pallet truck is defined as the x direction, the length installation direction of the manual pallet truck is the y direction, and the height direction of the manual pallet truck is the z direction.

[0028] Such as Figure 1 ~ Figure 4 As shown, the present invention includes a y-direction clamping cylinder 1, a horizontal positioning cylinder 2, a v-shaped groove 3, a v-shaped block 4, a y-direction positioning block 5, a lower turret 6, an upper turret 7, and an x-direction clamping cylinder 11 , base 16, auxiliary base 17, wedge block 18, wedge block driving cylinder 19, worm gear pair 21, four identical electromagnetic chucks 10 and two lower turret clamping cylinders 14 with the same structure, two upper r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com