A method for comprehensive utilization of plant ash in biomass power plants

A plant ash, power plant technology, applied in the removal of solid waste, silicon compounds, alkali metal chlorides, etc., can solve the problems that do not involve ash and slag solutions, and achieve good application prospects, increased profits, and good economic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

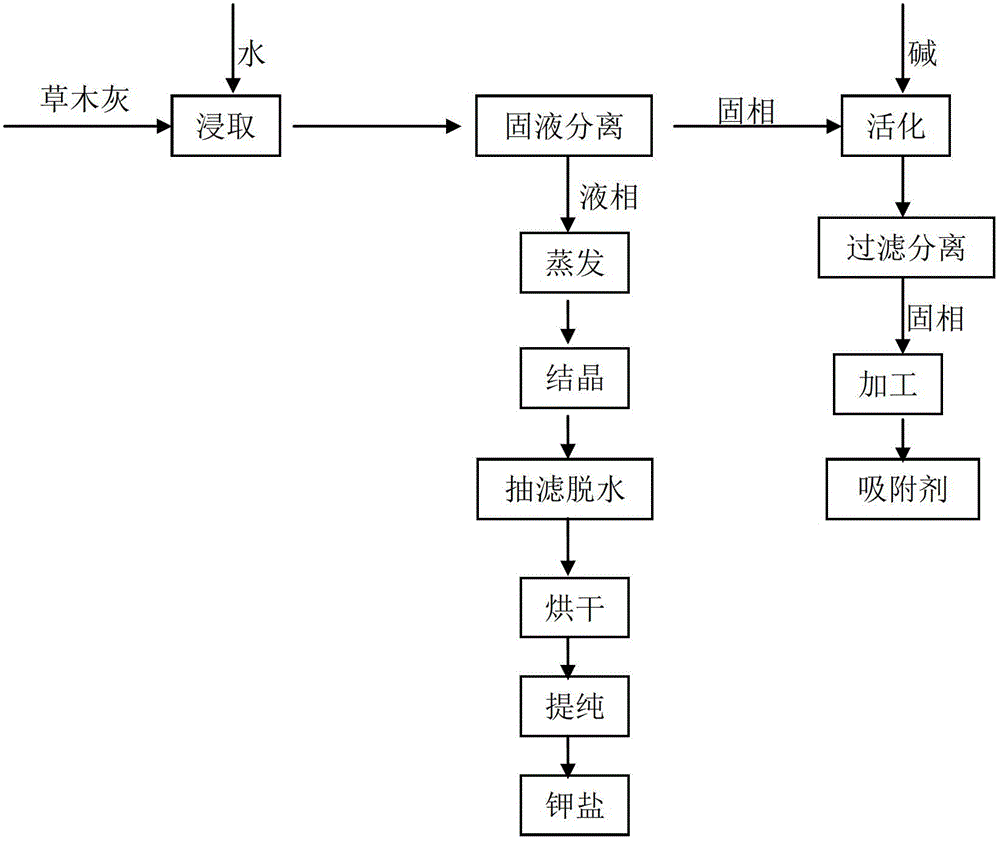

[0024] A method for the comprehensive utilization of plant ash in a biomass power plant, using the plant ash in a biomass power plant to prepare potassium salts and adsorbents, the process flow is as follows figure 1 ,Specific steps are as follows:

[0025] 1) Plant ash leaching: use deionized water as a solvent to extract plant ash produced by biomass power plants, wherein the mass content of potassium oxide is 7.54%, the mass ratio of gray to water is 1:2, and the leaching temperature is 70°C. The time is 2 hours, the stirring speed is 250r / min, so that the deionized water fully dissolves the soluble potassium salt in the plant ash.

[0026] 2) Solid-liquid separation: use a suction filtration device to separate the solid-liquid mixture, and ensure the separation effect, so that the residual potassium salt solution in the ash is as small as possible. Test the filtrate concentration with Baume meter to be 3~5°Bé.

[0027] 3) Preparation of potassium salt: The potassium filt...

Embodiment 2

[0032] A method for comprehensive utilization of plant ash in a biomass power plant, using the plant ash in a biomass power plant to prepare potassium salt and an adsorbent, the specific steps are as follows:

[0033] 1) Plant ash leaching: use deionized water as solvent to leaching the plant ash produced by biomass power plants for many times, in which the mass content of potassium oxide is 7.54%, the mass ratio of gray to water is 1:8, and the leaching temperature is 40°C. The leaching time is 4 hours, and the stirring speed is 250r / min, so that the deionized water can fully dissolve the soluble potassium salt in the plant ash.

[0034] 2) Solid-liquid separation: use a suction filtration device to separate the solid-liquid mixture, and ensure the separation effect, so that the residual potassium salt solution in the ash is as small as possible. Test the filtrate concentration with Baume meter to be 3~5°Bé.

[0035] 3) Preparation of potassium salt: The potassium filtrate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com