An energy feedback type three-phase high-voltage inverter

A high-voltage inverter and energy feedback technology, which is applied in the direction of converting AC power input to AC power output, output power conversion devices, electrical components, etc., can solve the problems of increasing the cost of inverter materials, increasing material costs, and complicated manufacturing processes. , to achieve the effect of reducing the number of solid-state power switches, prolonging the working life, and reducing the cost of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The energy feedback type three-phase high-voltage frequency converter of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments of the present invention.

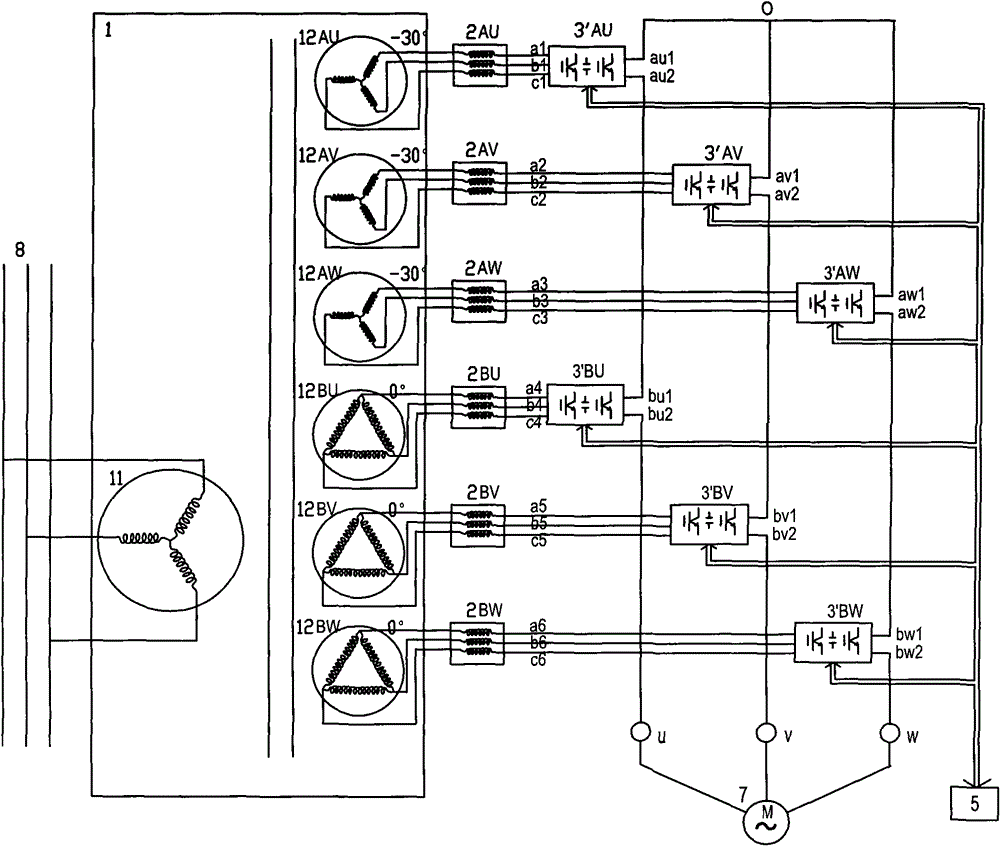

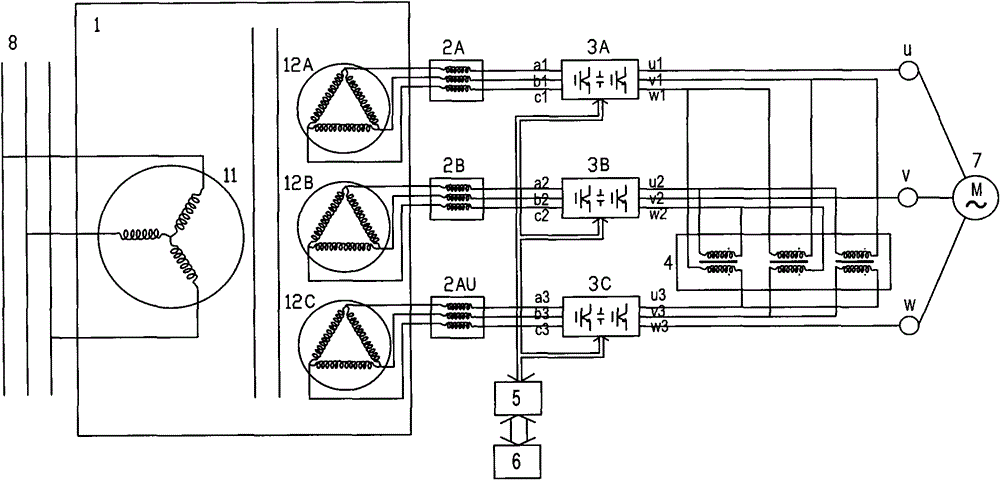

[0062] Figure 2A Describes an energy feedback type high-voltage inverter realized by three three-phase low-voltage inverters connected in series through three-phase transformer coupling output, which includes a main transformer 1, three (M=3) three-phase reactors (such as 2A), 3 An energy feedback type three-phase low-voltage frequency converter (such as 3A), a three-phase output transformer 4, a main controller 5 and a sensor circuit 6. If the input and output voltages of the low-voltage inverter are both three-phase 660V, then Figure 2A It can realize a three-phase AC 2000V voltage input-output high-voltage inverter, and its capacity is the sum of three low-voltage inverters.

[0063] The main transformer 1 is a three-phase multi-channel sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com