Variable reluctance motor and rotor structure thereof

A variable reluctance, rotor technology, applied in the shape/style/structure of the magnetic circuit, the rotating parts of the magnetic circuit, the static parts of the magnetic circuit, etc. Variable reluctance motor limitation and other problems, to achieve the effect of improving vibration and noise problems, reducing iron loss, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

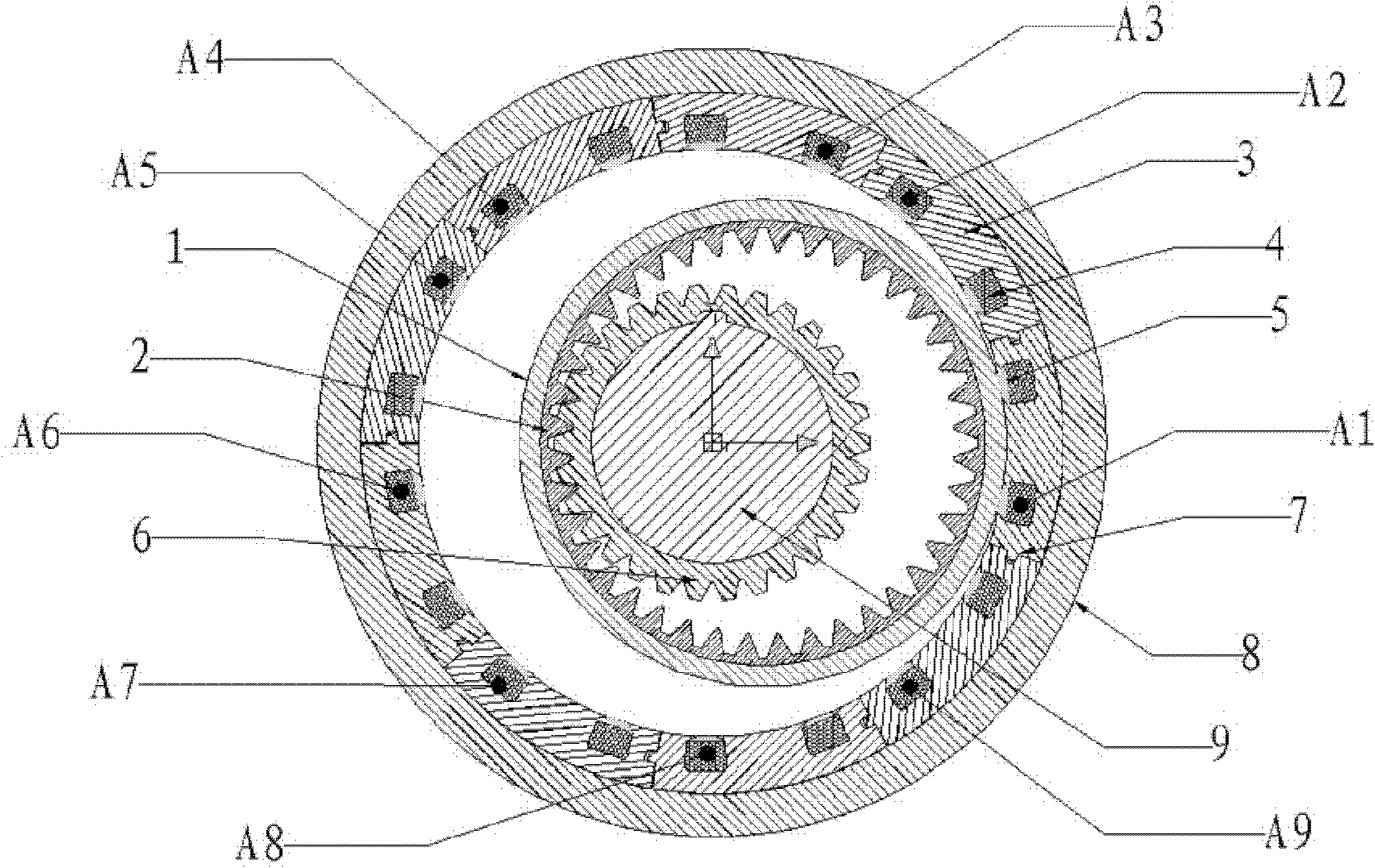

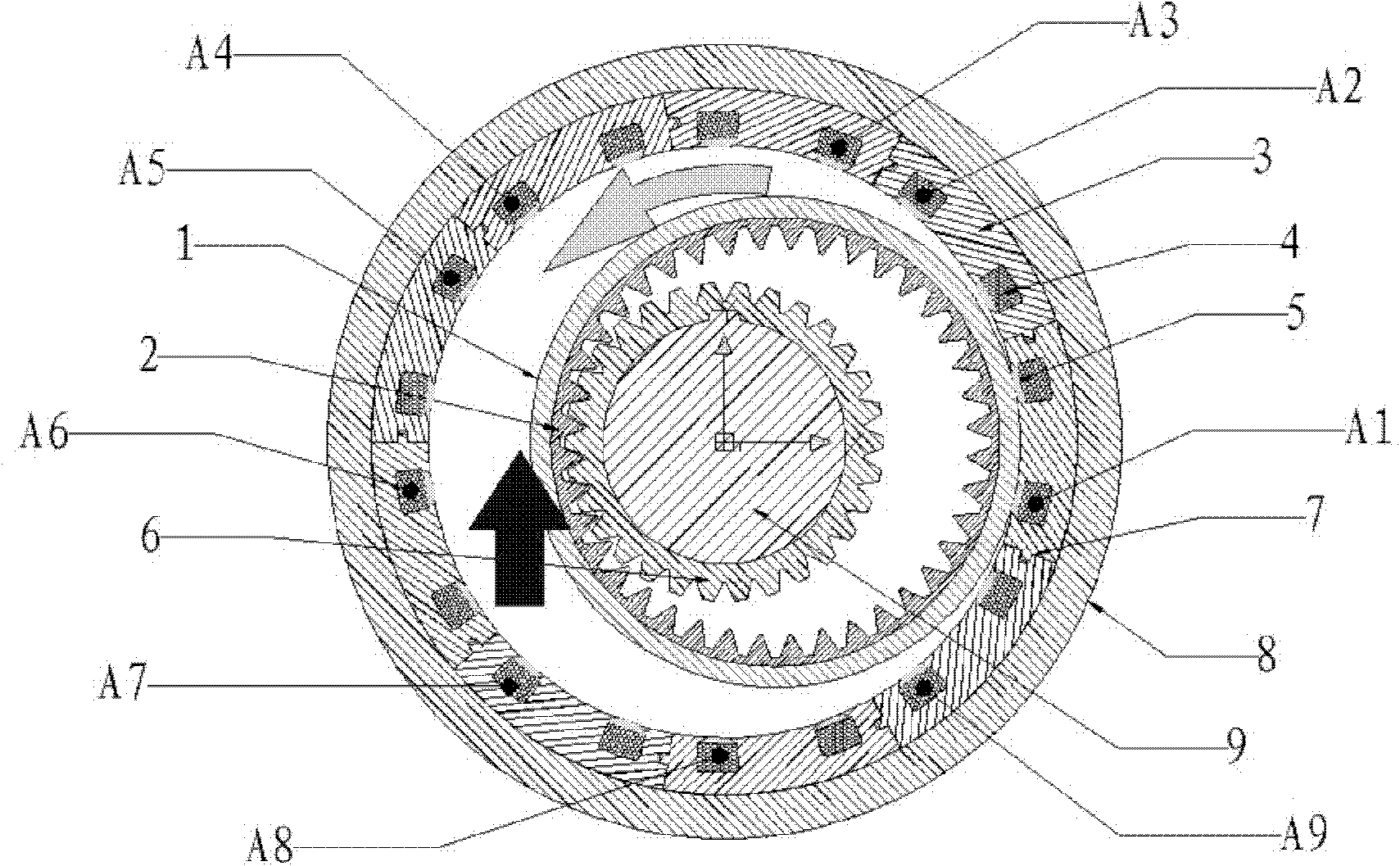

[0031] refer to figure 1 , the figure is a schematic structural diagram of a specific embodiment of the variable reluctance motor of the present invention.

[0032] The variable reluctance motor of this embodiment includes a stator part, a rotor part and an excitation winding 4. In addition, in this embodiment, the stator part includes a plurality of E-shaped stator segments 3, and the plurality of E-shaped stator segments 3 are The circumferential direction is evenly arranged, and the inner circular surface of the stator can be cylindrical or drum-shaped. The above stator segment 3 is installed in the inner circular surface of the motor base 8, and each E-shaped stator segment assembly is spaced from each other by a certain air gap 7 Or evenly installed along the inner circle of the machine base without air gap. In the specific implementation, the E-shaped stator segment 3 components can be laminated with soft magnetic material sheets, and the openings of the two slots of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com