Control method and system of intelligent threaded rod juicer

A control system and intelligent screw technology, applied in general control systems, control/regulation systems, computer control, etc., can solve problems such as difficulty in completely avoiding the hidden danger of motor burnout, inability to select the speed of juicing, affecting the effect of juicing, etc. Complete functions, improve whipping efficiency, and improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

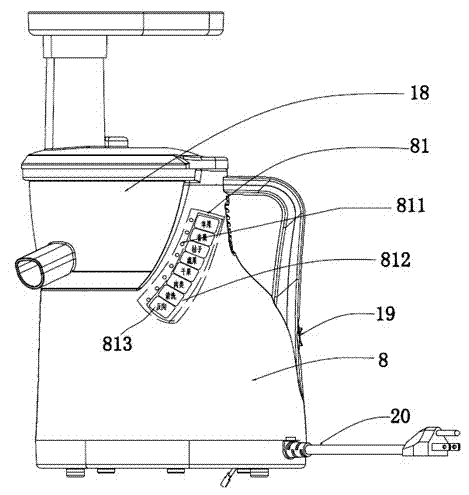

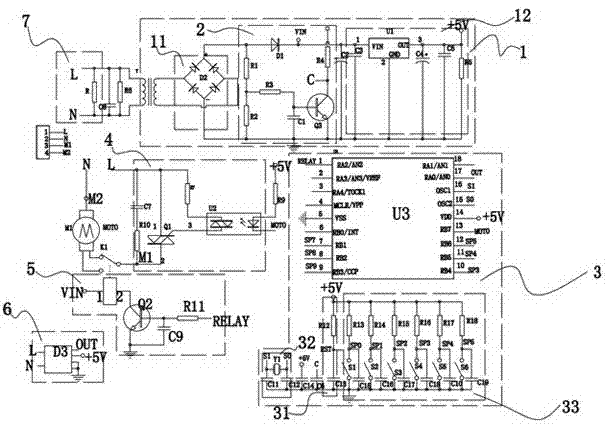

[0023] Such as figure 1 , figure 2 As shown, the control method of the intelligent screw juice extractor provided by the present invention includes a power cord 20, a host 8, a motor 9, a control system 10, a squeezing device 18 and a switch 19, the control system 10 is placed in the host 8, and the host 8 There is a control panel 81 on the top, and the control panel 81 is provided with juicer function buttons 812 for different food materials. The buttons 812 cooperate with the control system 10, and each button 812 corresponds to a different motor speed or speed change mode. And the function of feedback feeds back the information that the load is too large to the controller, thereby controlling the intermittent reverse rotation of the motor, loosening the food materials in the pressing device 18 and reducing the load.

[0024] An indicator light 811 and a reverse button 813 are provided on the control panel 81, and the reverse button 813 realizes the intermittent reverse fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com