Diesel heating device for vehicle

A diesel heating and diesel technology, which is applied in the direction of fuel heat treatment device, charging system, engine components, etc., can solve the problem of increased local airflow resistance, broken teeth of drive gear pairs, and limited environmental adaptability of vehicle diesel heating devices, etc. problem, achieve the effect of improving the air circulation state and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

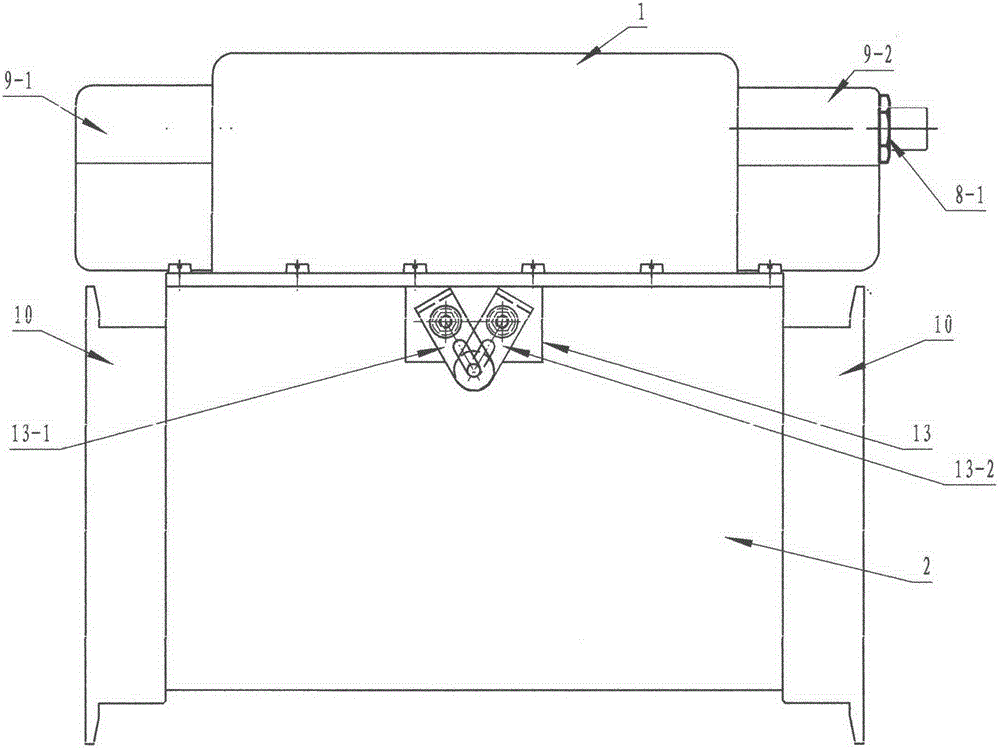

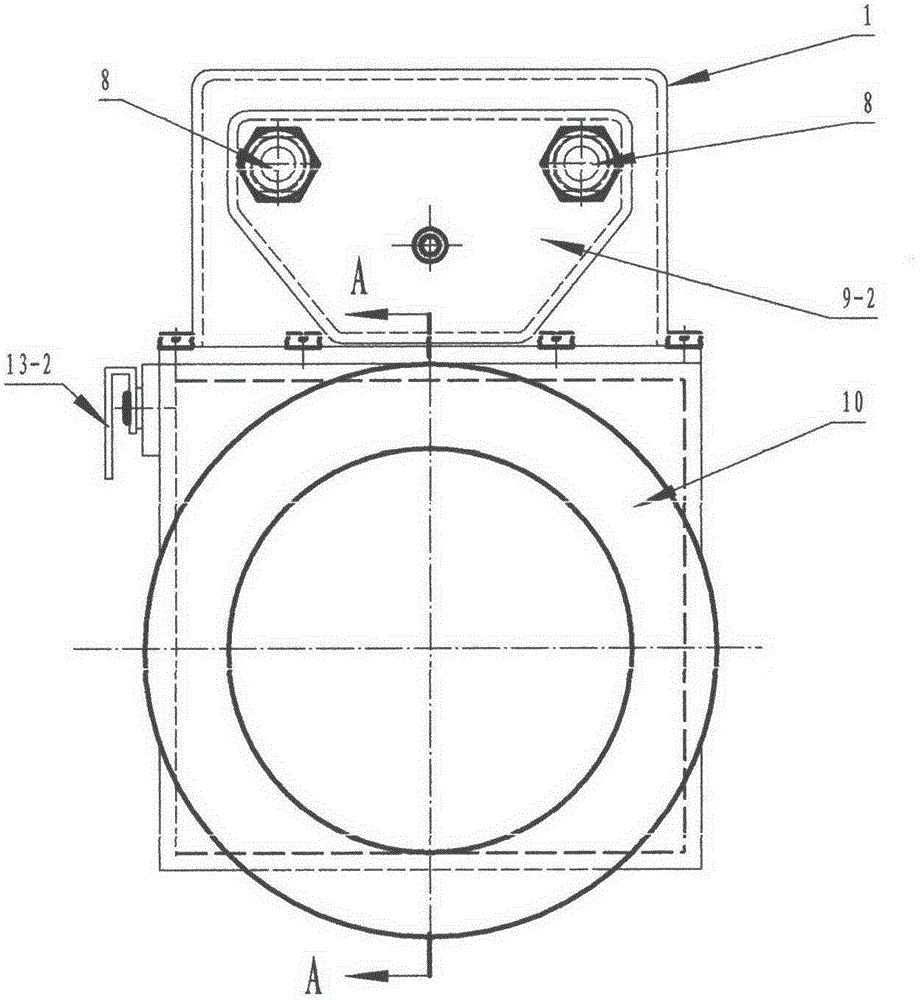

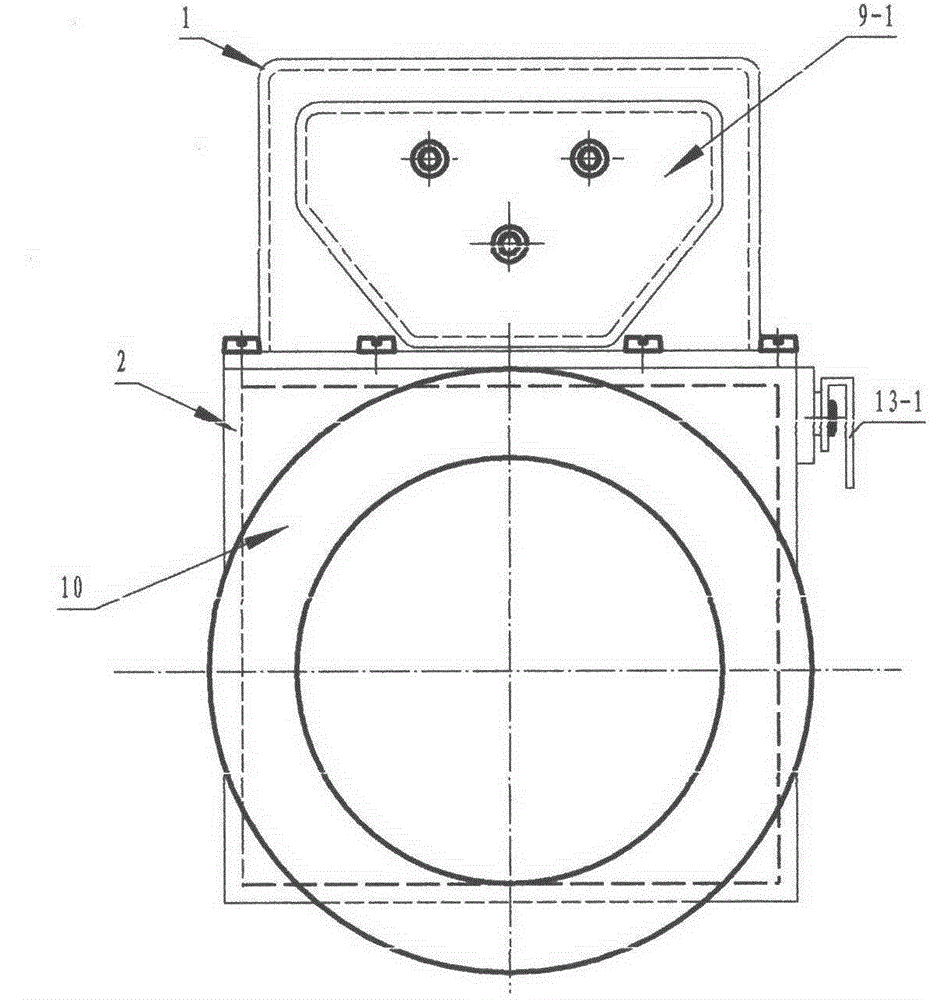

[0043] see Figure 4 , combined with figure 1 , figure 2 , image 3 . The vehicle diesel heating device is an assembly of upper and lower structures composed of the exhaust heat collection and exchange box (1) and the exhaust flow control box (2) connected by bolts. The exhaust flow control box is equipped with diversion control Plate synchronous drive system (13).

[0044] see Figure 4 , combined with Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 . Exhaust gas heat collection and exchange box (1) is a combination of fixed wall panels (1) and movable wall panels (6) on both sides through a concave-convex tenon structure. The bottom of the box is opened as an exhaust gas inlet and outlet channel (15). The other three sides are closed box-shaped boxes; the movable wallboard (6) is provided with heat pipe support holes (7), and there are sealing grooves for placing graphite sealing rings (16) and cover connecting seats (14) in the support h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com